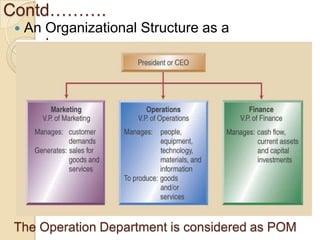

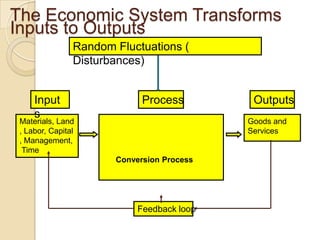

The document discusses the system approach of production functions. It states that a production function is a system comprised of various sub-systems that work together, including inputs, conversion processes, outputs, random fluctuations, and feedback. Inputs are resources that enter the production system like materials, labor, capital and time. These inputs go through a conversion process where their utility and economic value are increased. The outputs of the system are the goods and services produced. Random fluctuations are unplanned events that can influence production. Feedback is the system's control mechanism that helps adjust activities based on goals and results.