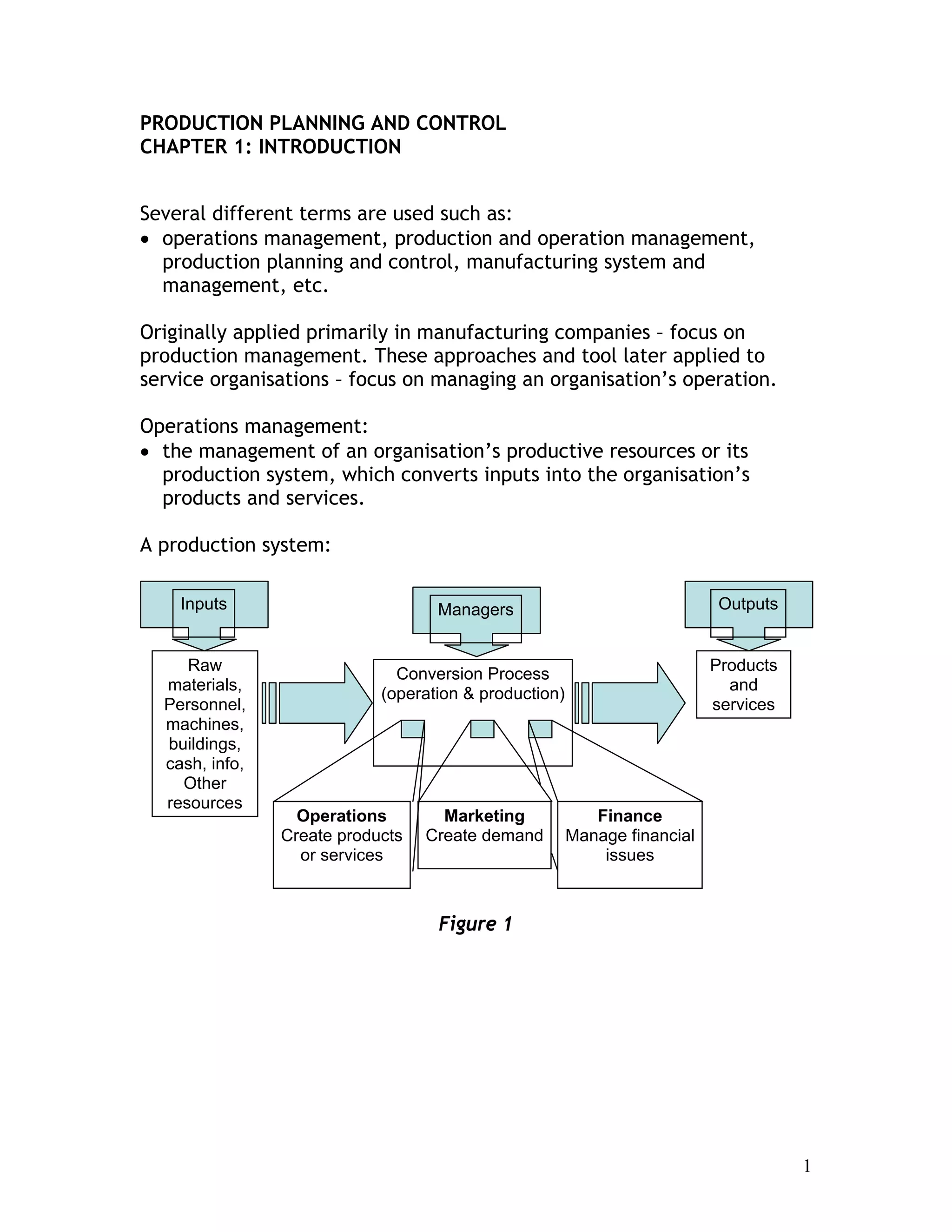

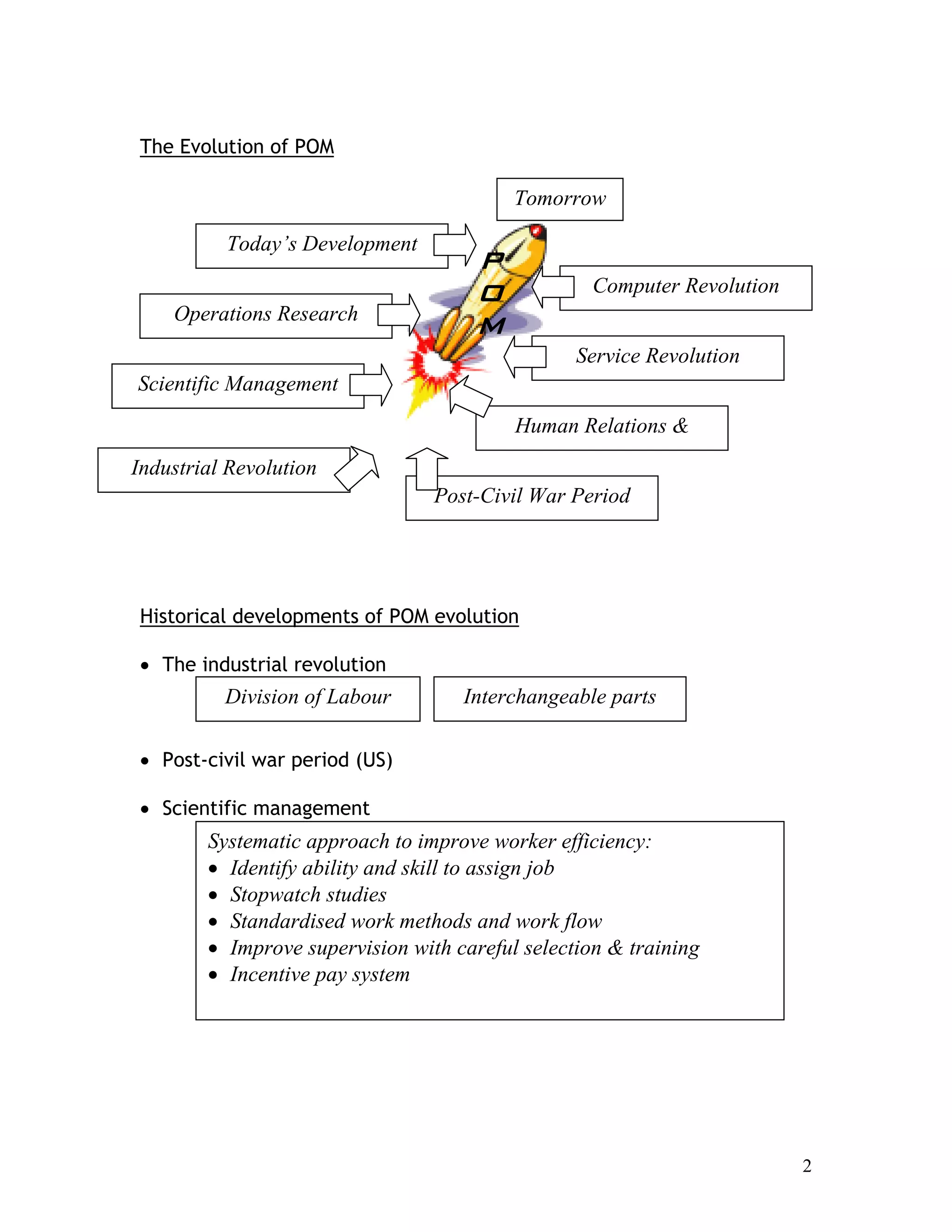

This document provides an introduction to production planning and control (POM). It discusses key terms in POM like operations management. POM focuses on managing an organization's production system to convert inputs into products and services. The evolution of POM is then summarized, from the industrial revolution to developments in scientific management, human relations, operations research, and computer technology. Influential contributors to the development of POM concepts are also listed.

![5

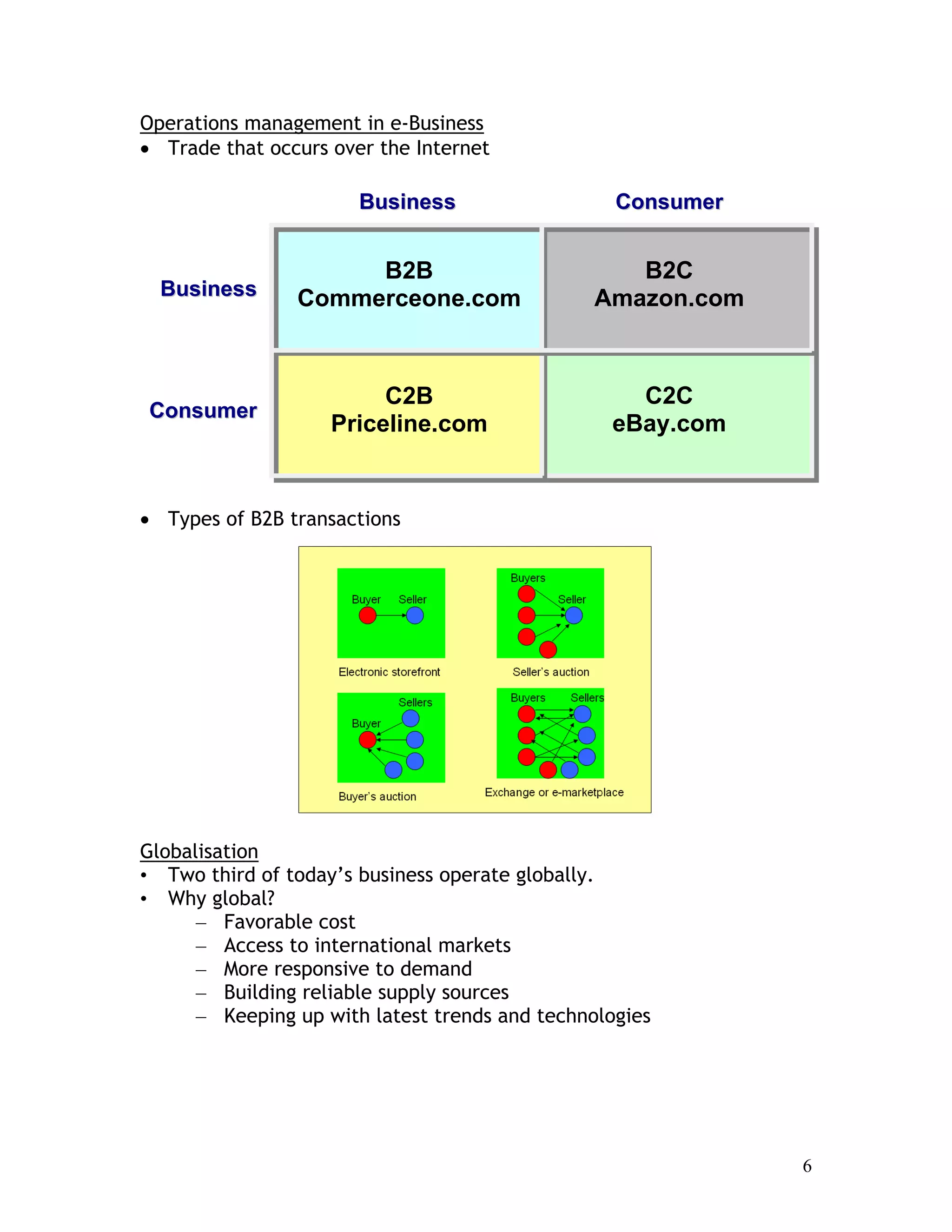

Decision making in POM

Assignment 1

Find at least three (3) entry-level jobs (in Malaysia) at three (3) different

companies which are related to the production and operations

management function. Describe the jobs and how they are related to the

production and operation management. Describe the companies,

mentioning what type of prodcution system they are, primary inputs,

conversion subsystem and outputs. You could search for the jobs at

Jobstreet (www.jobstreet.com) or JobsDB (www.jobsdb.com).

[][][]

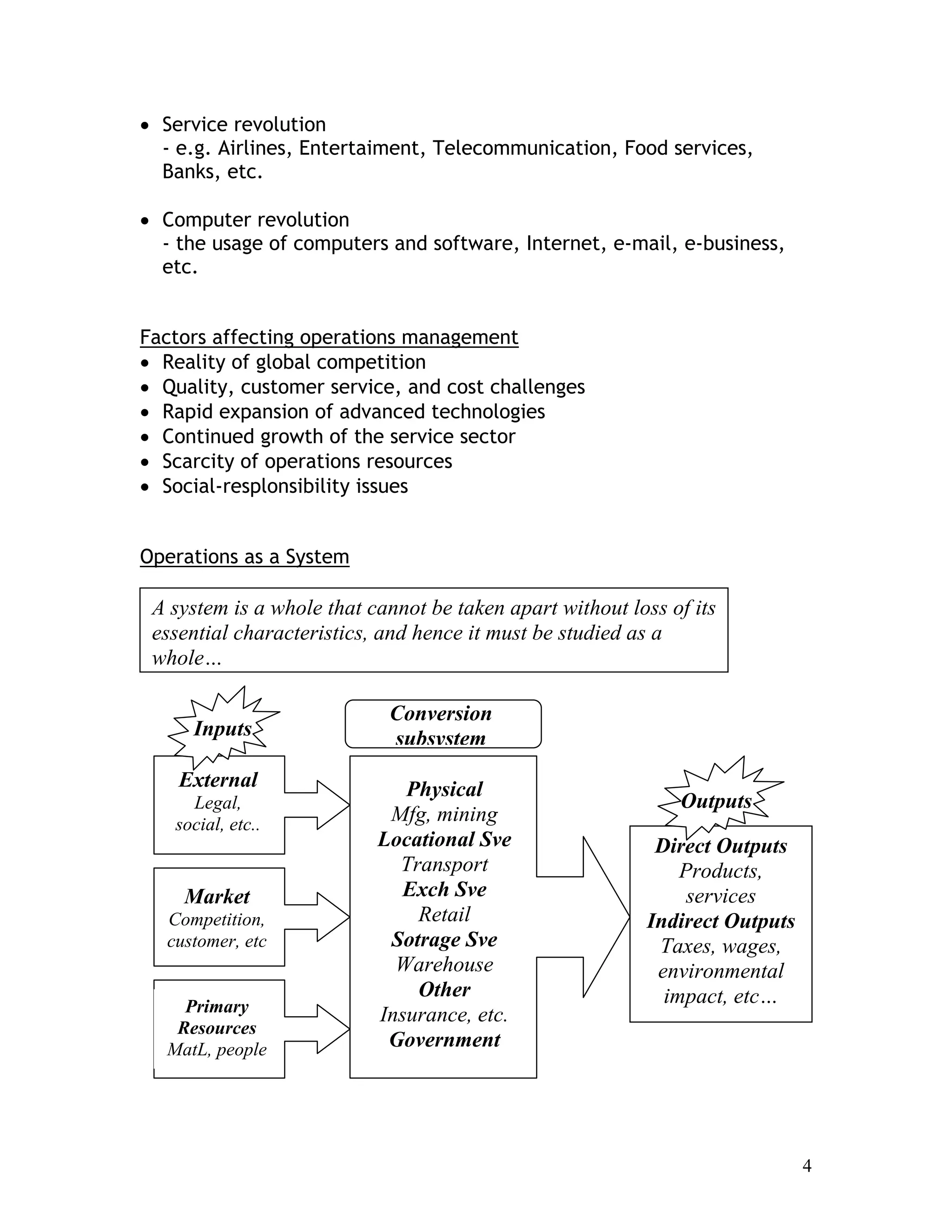

Strategic

Decision

Operating

Decision

Control

Decision

Decisions about products, processes, and

facilities. These decisions are of strategic

importance and have long-term significance for

the organisation

Decisions about planning production to meet

demand. These decisions are necessary if the

ongoing production of goods and services is to

satisfy the demands of the market and provide

profit for the company

Decisions about planning and controlling

operations. These decisions concern with the

day-to-day activities of workers, quality of

products and service, production and overhead

costs, and maintenance of equipment.](https://image.slidesharecdn.com/l2-130507022655-phpapp01/75/L2-5-2048.jpg)