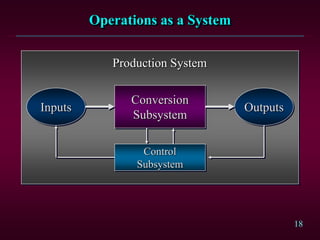

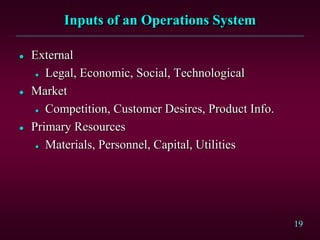

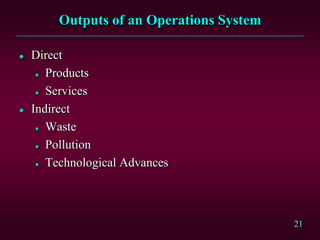

This document provides an overview of production management. It discusses the historical milestones in operations management such as the Industrial Revolution, scientific management, and the computer revolution. It also covers the different ways of studying operations management, including viewing production as a system and the three types of decisions: strategic, operating, and control. The goal of operations management is to efficiently manage an organization's resources and production process.