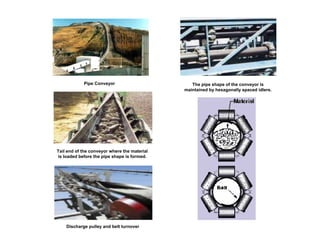

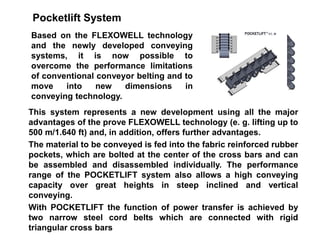

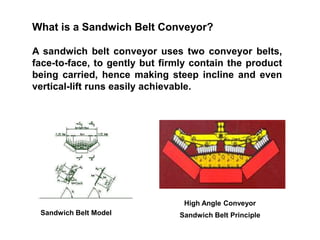

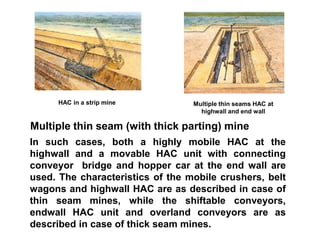

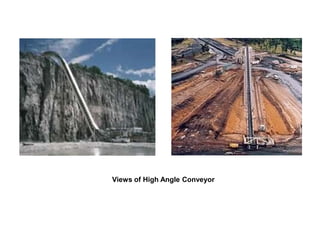

This document discusses high angle conveying systems used in surface mines as an alternative to hauling material by truck. It describes several types of high angle conveyor systems, including pipe conveyors, flexowell conveyors, pocketlift conveyors, and sandwich belt conveyors. It focuses on describing the sandwich belt conveyor system in detail, explaining how it uses two conveyor belts pressed together to gently contain material and allow conveying up extremely steep angles, sometimes vertically.