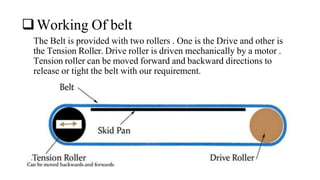

This document provides an overview of belt conveyor systems. It begins with an introduction to conveyors and their use in transporting materials in industries. It then discusses different types of conveyors, focusing on belt conveyors. The key components and working of belt conveyors are explained. The document discusses belt materials, properties, advantages, and limitations of belt conveyor systems. It concludes that belt conveyors can improve efficiency in industries by transporting raw materials and products through production processes.