This document provides information about belt conveyors, including their history, components, working principles, types, and advantages/disadvantages. Some key points:

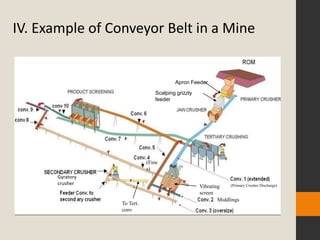

- Belt conveyors transfer material along an endless loop of belt between two pulleys and are used widely in manufacturing and mining.

- Their development began in the 19th century and they were introduced on assembly lines in 1913.

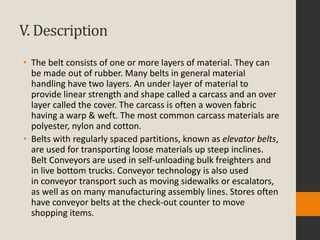

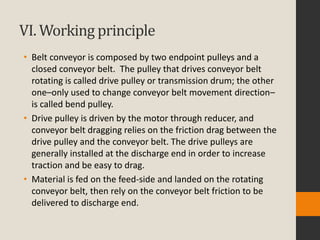

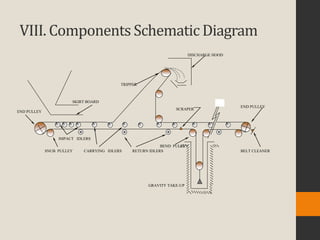

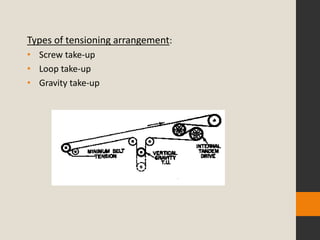

- The basic components are the belt, idlers, drive head, and tensioning system. The belt moves on pulleys and idlers while being powered by the drive head.

- Belt conveyors can be flat, trough, or other designs and are used horizontally, at inclines, or declines depending on the application.