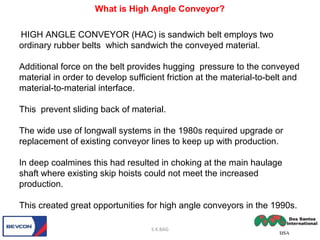

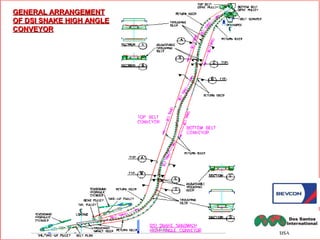

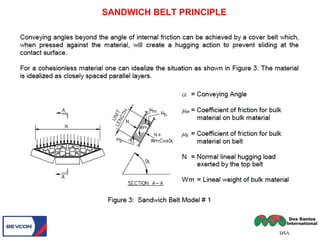

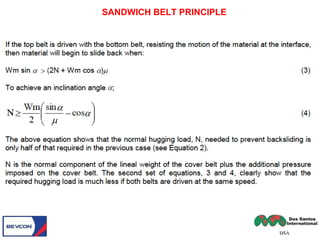

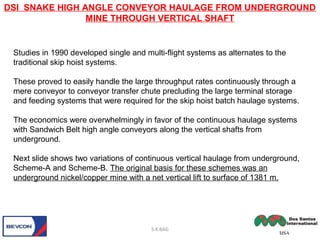

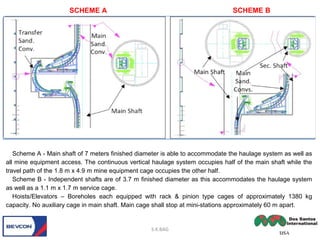

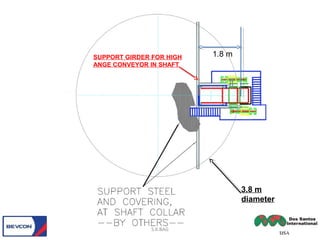

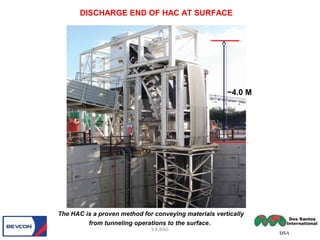

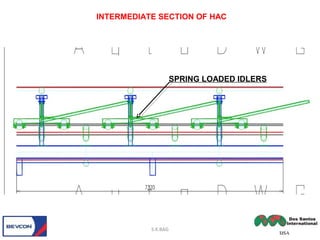

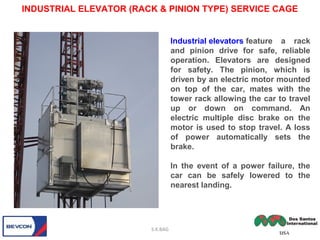

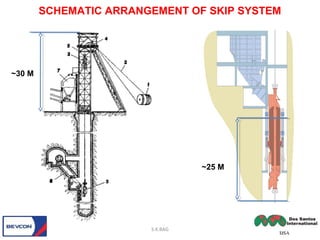

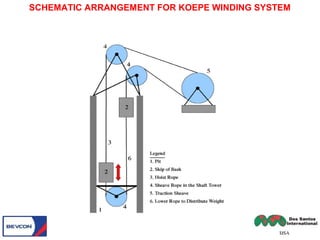

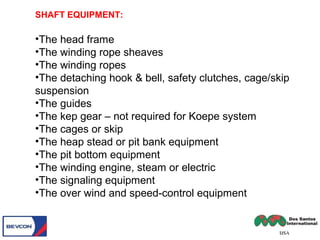

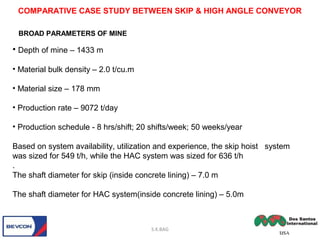

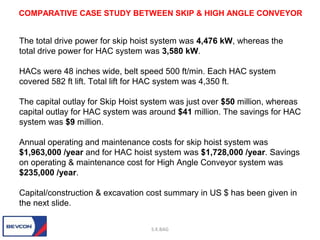

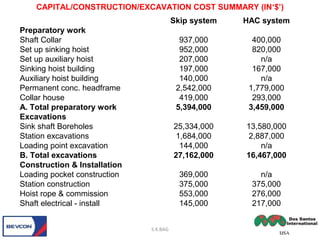

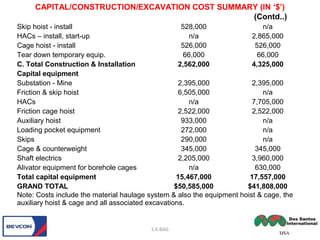

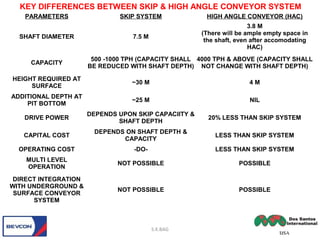

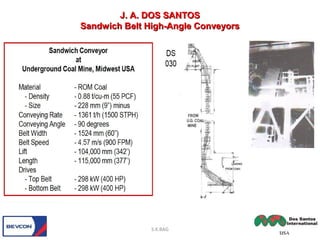

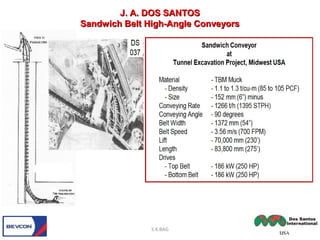

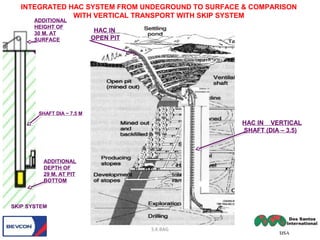

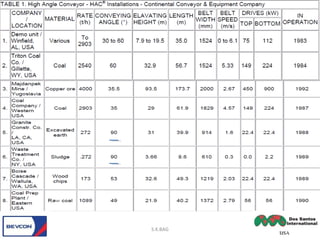

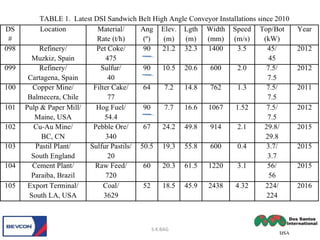

The document discusses the development and advantages of high angle conveyors, particularly the DSI Snake sandwich belt system, for vertical transport from underground mines. It highlights a comparative case study demonstrating significant cost savings and operational efficiency of high angle conveyors over traditional skip hoist systems. The author emphasizes the potential for increased production in coal mining applications through the use of high angle conveyor systems in Indian underground mines.