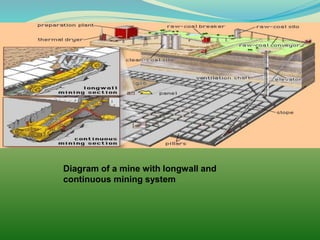

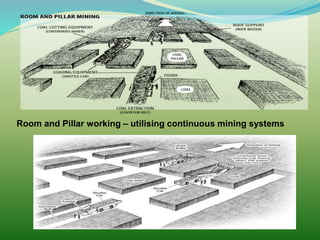

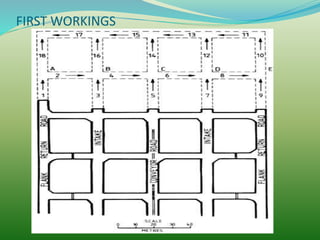

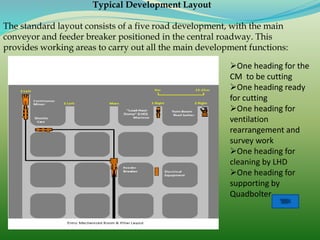

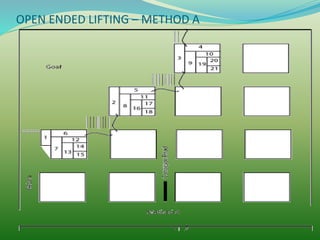

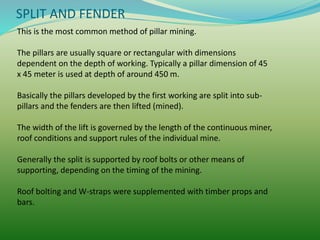

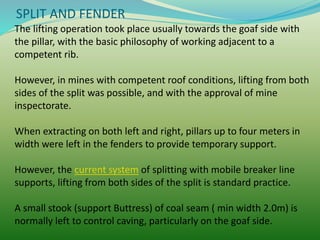

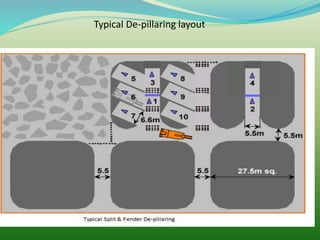

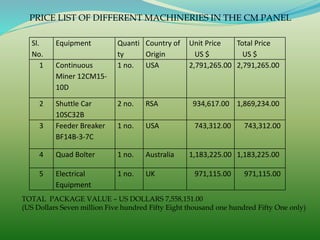

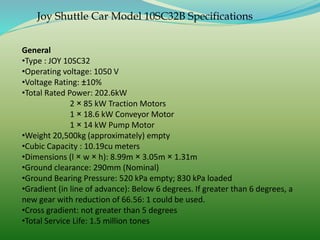

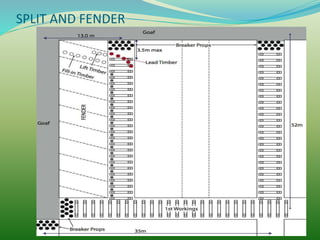

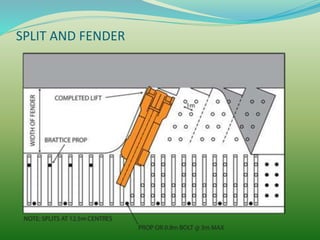

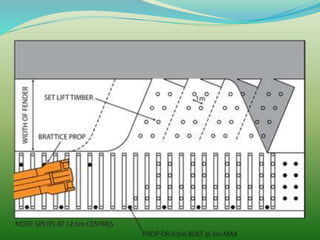

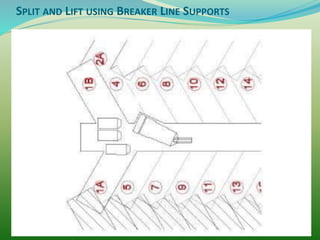

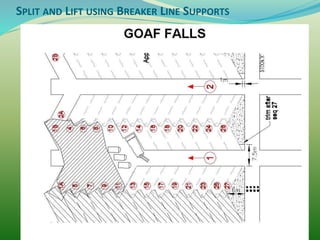

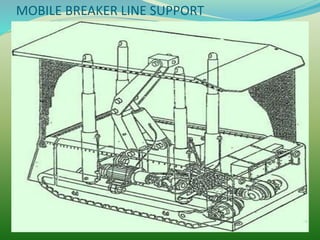

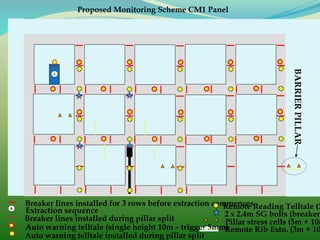

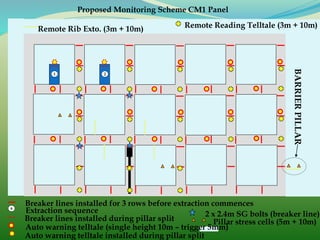

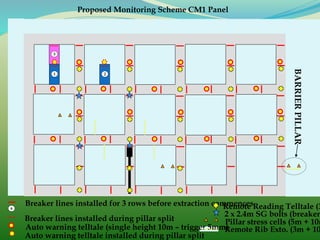

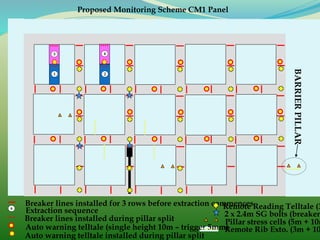

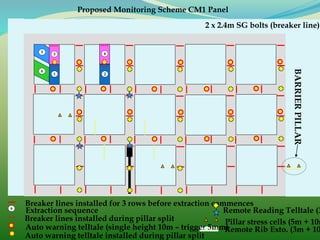

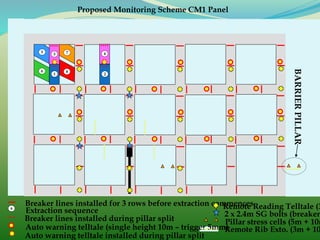

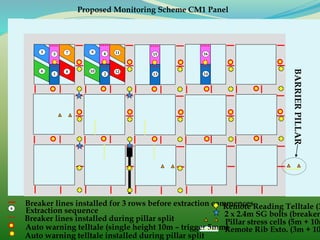

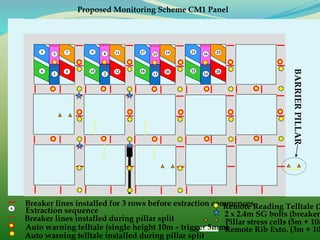

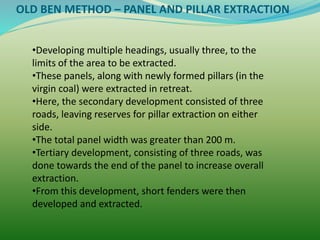

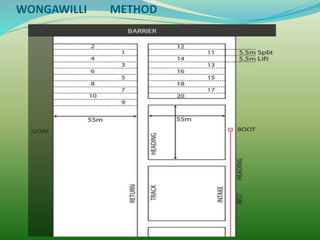

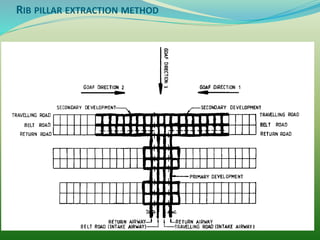

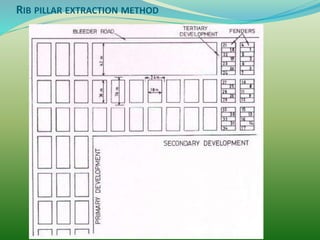

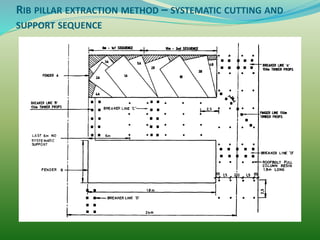

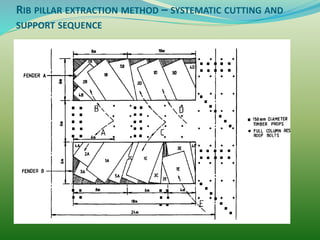

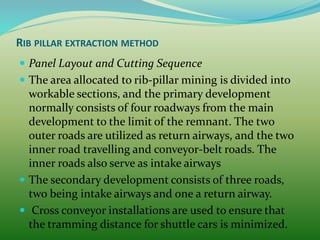

This document provides information about online test series, study materials and video lectures for various mining exams conducted in India. It also provides contact details for ordering mining books and for queries. The document discusses various continuous mining systems like longwall mining and room and pillar mining. It provides details about first workings, typical development layout, pillar extraction methods like split and fender mining and lift mining using breaker line supports. Equipment used in continuous miner panels like continuous miners, shuttle cars, feeder breakers and their specifications are also summarized.