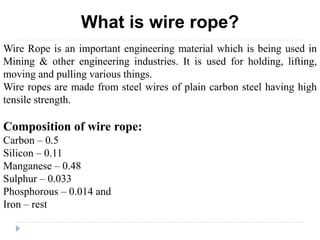

1. Wire rope is used for lifting, holding, and pulling loads in mining and other industries. It is made of steel wires twisted together.

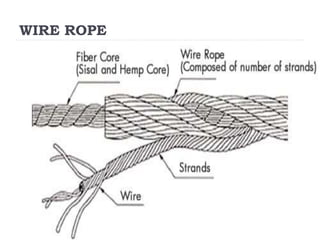

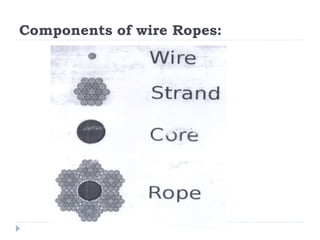

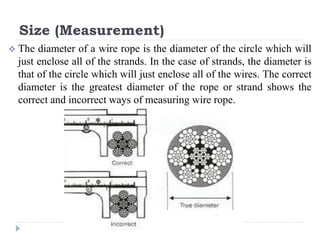

2. A wire rope consists of wires twisted together to form strands, which are then twisted together to form the rope. The core provides flexibility and lubrication.

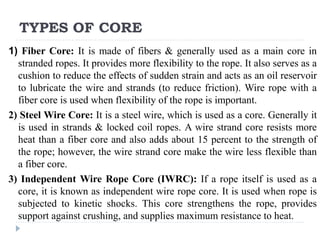

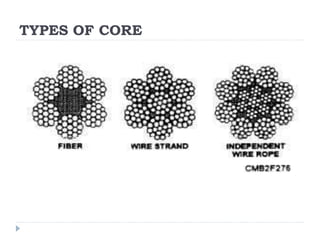

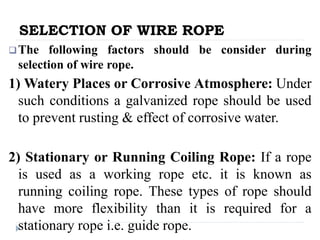

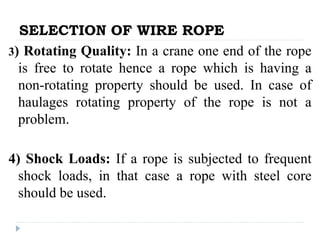

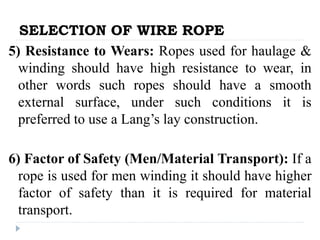

3. Wire ropes are selected based on factors like flexibility, resistance to wear, crushing strength, and whether the rope needs to be stationary or rotating. Fiber cores provide more flexibility while steel cores provide more strength.