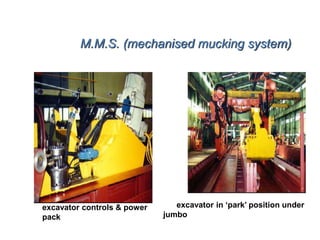

The document discusses various topics related to blasting and mucking in mines. It describes different types of cuts used for blasting weaker vs tougher rocks. It explains the common pattern of charging blast holes, with 2/3 filled with explosive and the remaining 1/3 with stemming material. It provides a formula for calculating the number of blast holes needed based on the powder factor and weight of explosives and rock. Finally, it discusses mucking, the loading of exploded materials, and the main machinery used for this in coal mines: side discharge loaders and load haul dump vehicles.