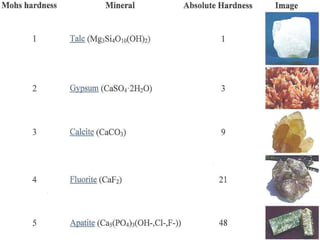

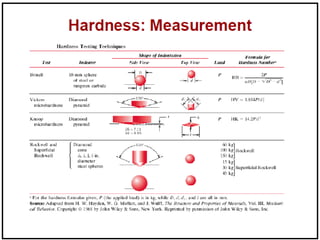

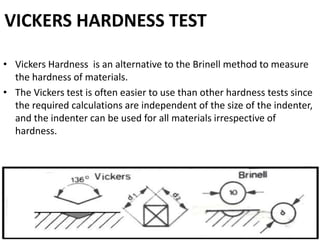

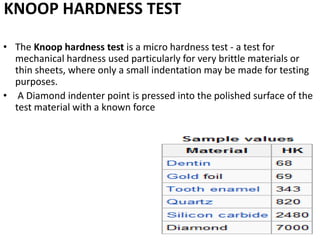

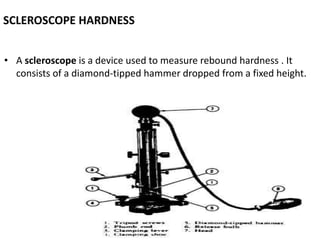

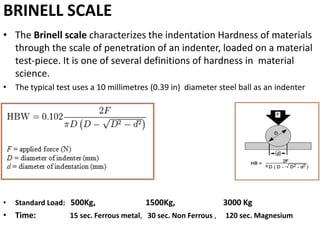

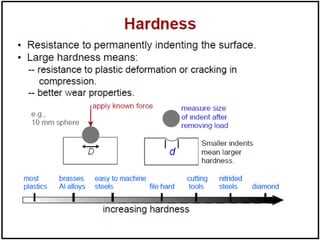

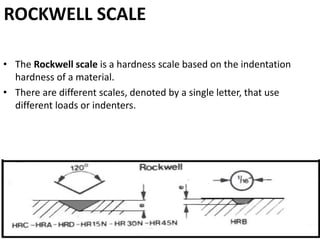

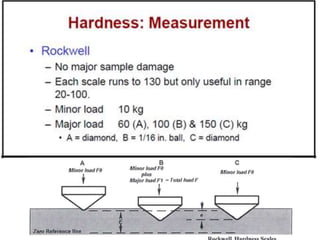

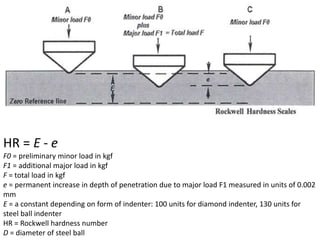

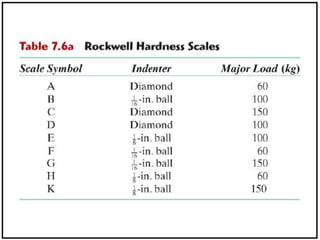

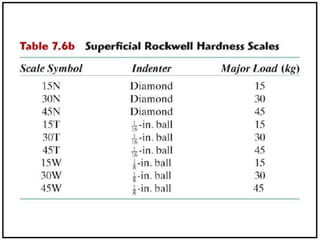

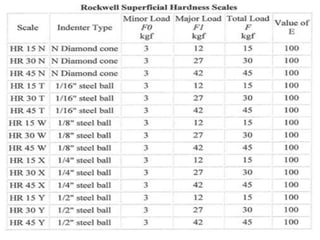

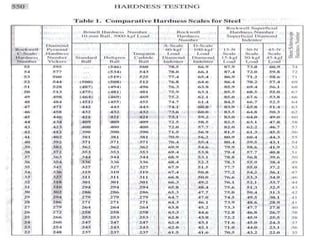

One if the mechanical properties that may be important to consider is hardness which is a measure of material’s resistance to localized plastic deformation. There are several different tests to measure hardness, including Mohs, Vickers, Knoop, Scleroscope, Brinell, and Rockwell. The Vickers test uses a diamond indenter and measurements are independent of indenter size, while the Knoop test is used for brittle materials where only a small indentation can be made. The Scleroscope test measures rebound hardness using a dropped diamond-tipped hammer, and the Brinell test uses a steel ball indenter under a standard load and time. The Rockwell test indentation hardness that uses different loads or