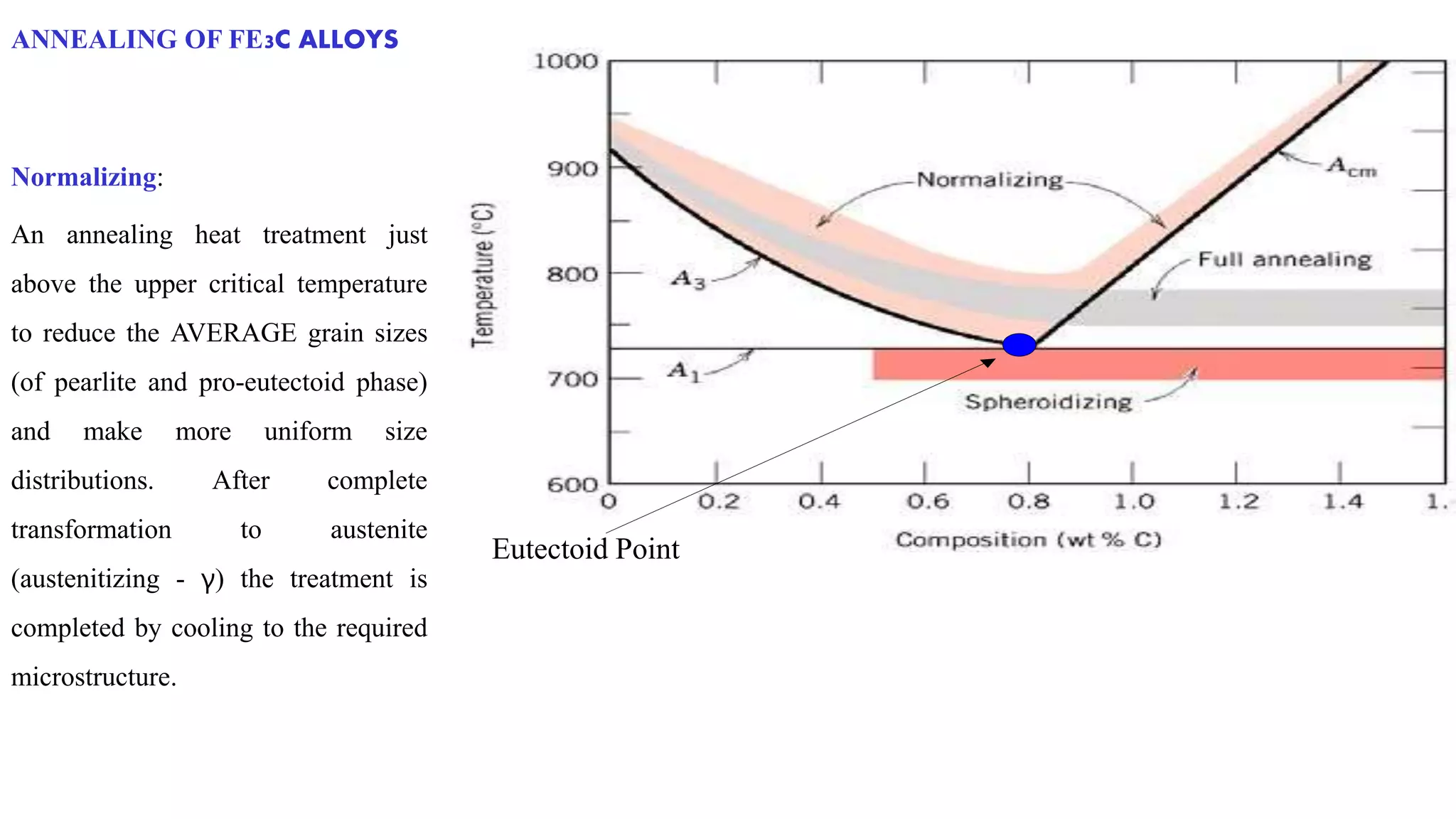

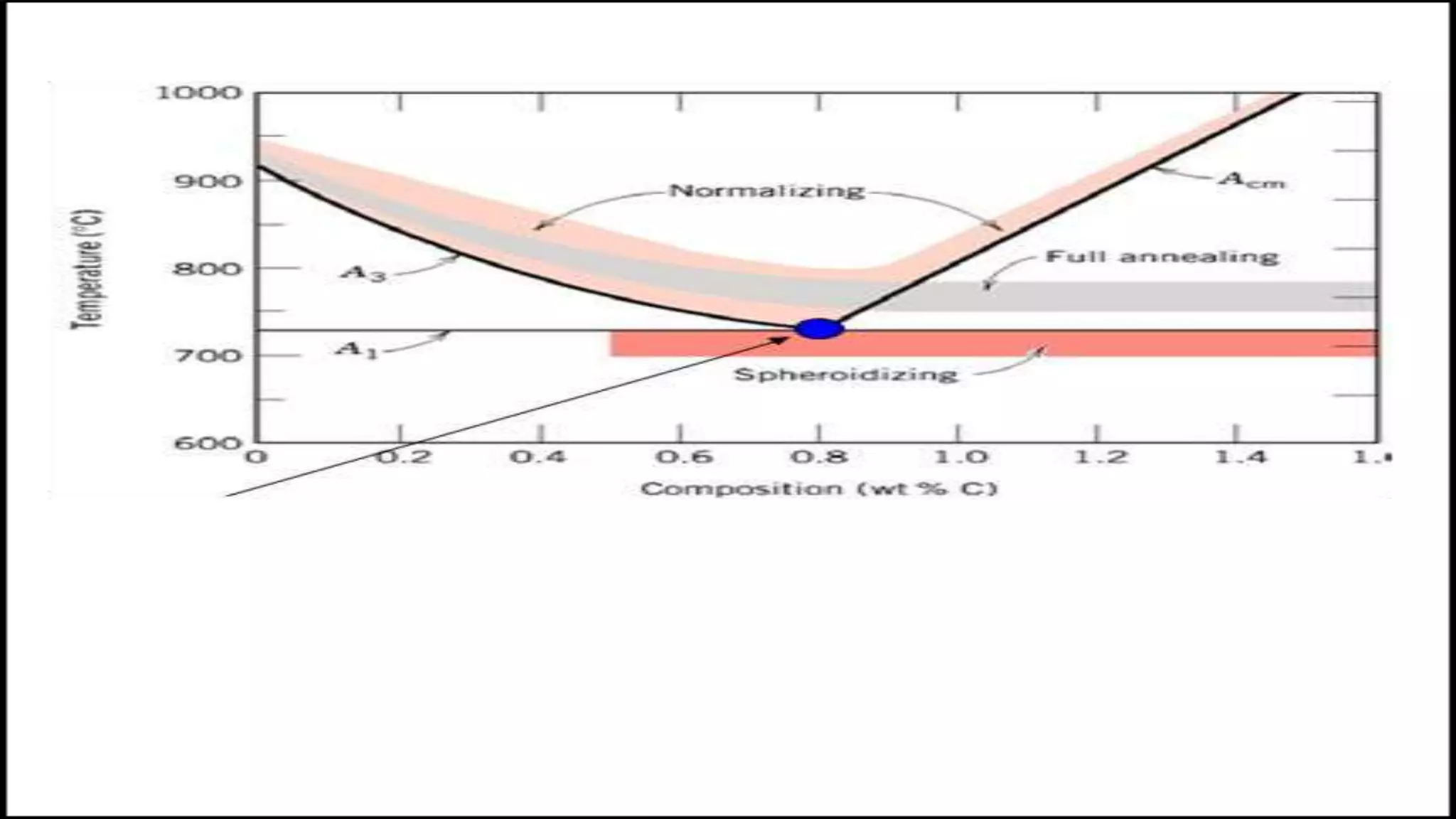

This document discusses various metal fabrication processes and heat treatments. The main metal fabrication processes covered are cutting, folding, punching, shearing, welding, forging, rolling, extrusion and drawing. Common raw materials used include plate metal, tube stock, welding wire, castings and fittings. Annealing heat treatments are also summarized, which involve heating metal to high temperatures to relieve stresses, increase softness and ductility, and produce desired microstructures, followed by controlled cooling. The stages of annealing and different types of annealing like normalizing and full annealing are defined.