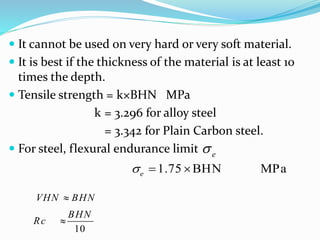

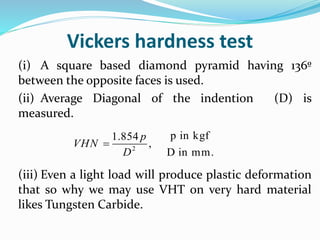

Hardness is a material property that describes resistance to indentation. It is influenced by factors like carbon content in steel. Common hardness tests include Brinell, Rockwell, Vickers, and microhardness Knoop testing. Brinell testing involves indenting a specimen with a hard ball under load and measuring the diameter. Rockwell uses an indenting cone to measure depth. Vickers and Knoop are for very hard materials and measure indention diagonal length. Hardness values correlate to other properties like tensile strength. Hardness testing is used to evaluate properties but is not the only factor in assessing mechanical behavior.