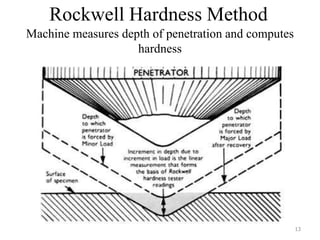

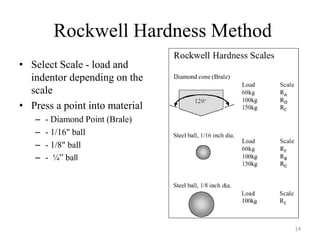

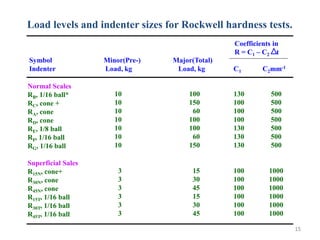

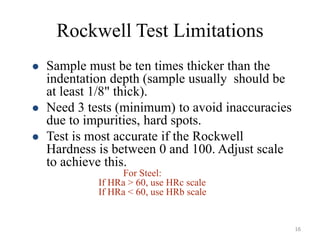

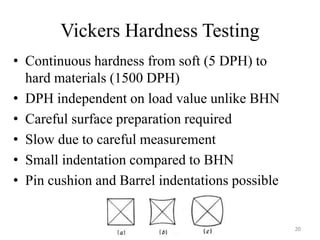

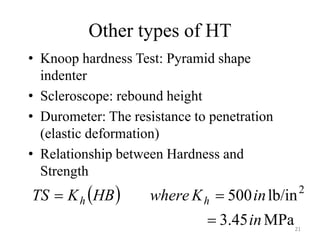

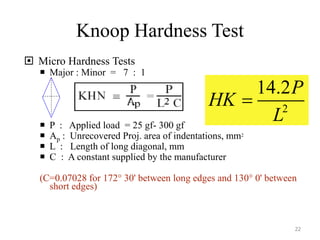

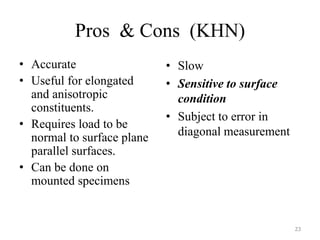

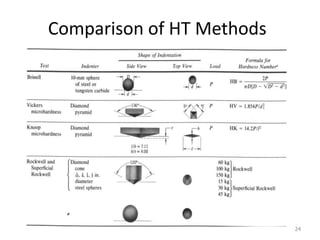

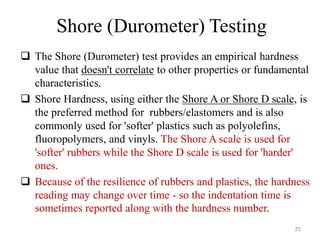

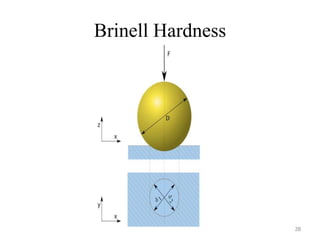

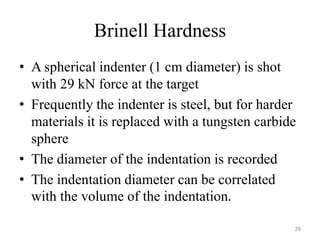

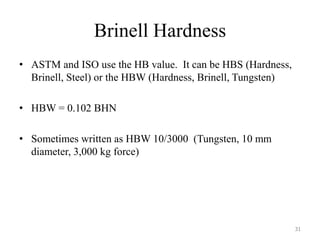

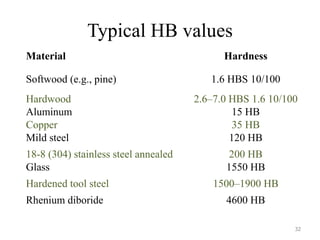

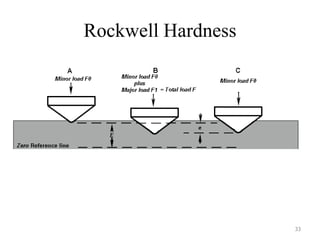

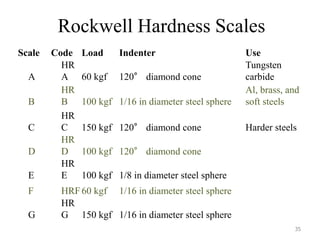

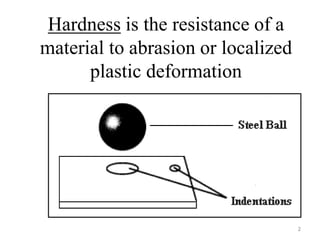

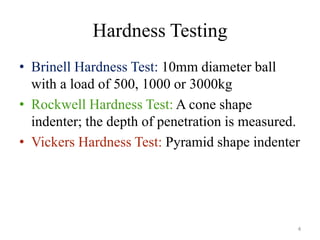

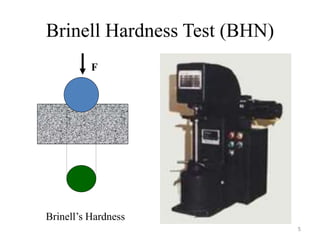

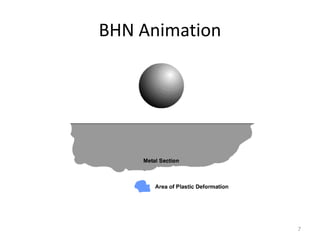

This document discusses different methods of hardness testing, including Brinell hardness testing, Rockwell hardness testing, Vickers hardness testing, and Shore hardness testing. Brinell hardness testing involves indenting a material with a 10mm diameter steel ball under a load and measuring the diameter of the indentation. Rockwell hardness testing uses different indenters and loads depending on the scale to measure depth of penetration. Vickers hardness testing uses a pyramid shaped indenter to measure hardness. Shore hardness testing provides an empirical hardness value for rubbers and elastomers using either the Shore A or Shore D scale.

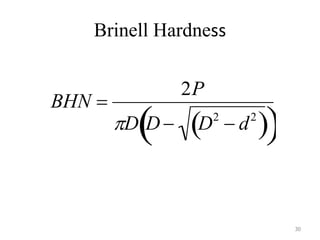

![Brinell Test Protocol

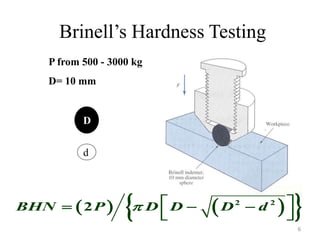

1. Press a 10mm (3/8") diameter ball into

material with a known amount of load.

2. Measure diameter of the indentation.

3. BHN = Load = 2L

Surface Area D[D-(D2-d2)1/2]

a) L = Load placed on ball, usually 3000 kg , but 1500 kg, and

500 kg can also be used.

b) D = Diameter of steel ball ( = 10 mm)

c) d = diameter of dent, measured by looking thru a Brinell

microscope.

8](https://image.slidesharecdn.com/56136194736135867052-231105072541-7c0b7c97/85/Materials-Testing-Lab-Presentation-8-320.jpg)