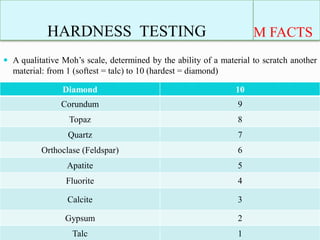

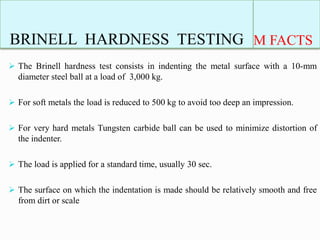

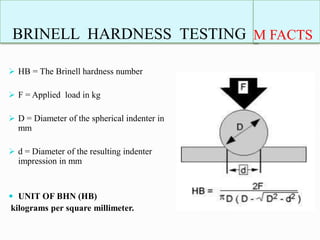

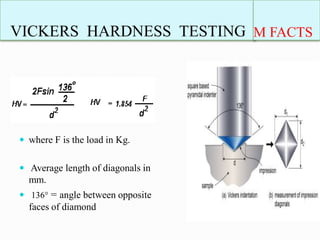

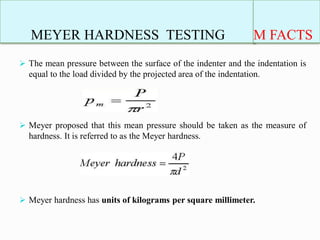

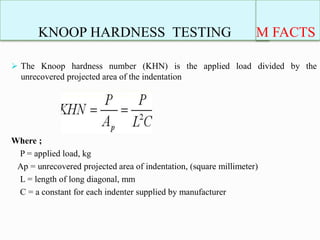

The document discusses different hardness testing methods. It describes Brinell hardness testing which uses a 10mm steel ball indenter under a load of 3000kg to test hardness. Vickers hardness testing uses a diamond pyramid indenter under loads ranging from 1-120kg. Rockwell hardness testing utilizes indentation depth under constant load to measure hardness using diamond cone or steel ball indenters under major loads of 60, 100, or 150kg. Microhardness testing uses Knoop indenters and low loads down to 25g to test small areas. Hardness is a measure of resistance to plastic deformation from indentation or abrasion.