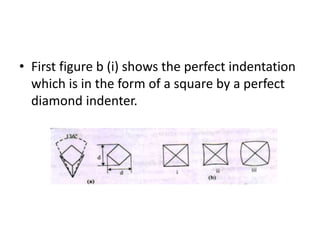

The document describes the Vickers hardness test. It uses a diamond pyramid indenter to make an indentation on the material being tested under a specified load ranging from 5 to 120 kg. The indentation left has a square shape regardless of load. The diagonal lengths of the indentation are measured under a microscope and used to calculate the Vickers hardness number, providing a continuous scale of hardness values. Factors like load, indentation shape, and temperature can affect the results. Advantages include consistency of indentation shape and suitability for testing a range of materials and surfaces. A disadvantage is it takes more time than other hardness tests.