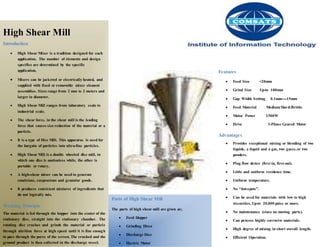

The high shear mill is a device used to reduce particle sizes through attrition force. It consists of a stationary disc and a rotating disc with a gap that particles are fed into. As the rotating disc spins at high speeds, the particles are crushed and grind against each other and the screens until they are small enough to pass through. High shear mills can be used across industries to mix, blend, and process liquids, gases, and powders. They provide efficient mixing through short processing times and uniform temperatures without hot spots. However, they also have high operating costs and produce dust during particle size reduction.