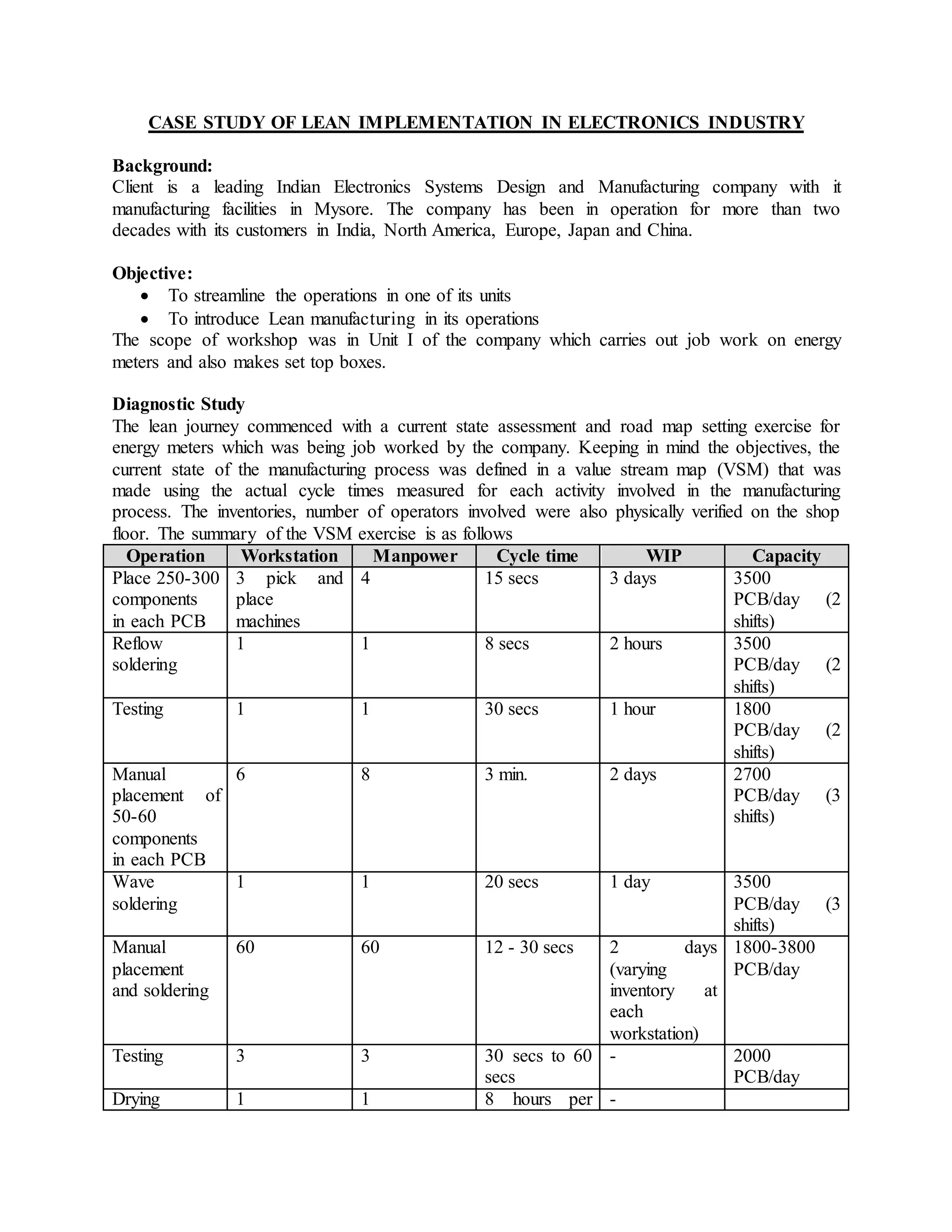

The document summarizes a case study of implementing lean manufacturing principles in an electronics company. It describes conducting an analysis of current operations, identifying areas for improvement, and implementing changes. Key points:

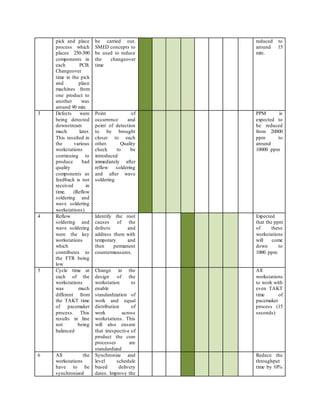

1) The company aimed to streamline operations and introduce lean. An analysis found throughput time varied from 4-6 days with quality issues.

2) Improvements included establishing flow between workstations, reducing changeover times from 90 minutes to 15 minutes, and moving quality checks closer to where defects occurred.

3) Results included reducing throughput time to 2 days, floor space by 60%, and improving quality levels and production flexibility. The lean implementation improved operations and addressed original objectives.