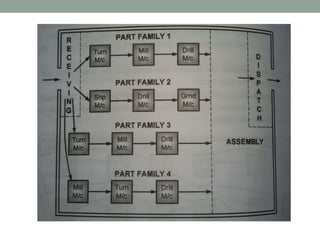

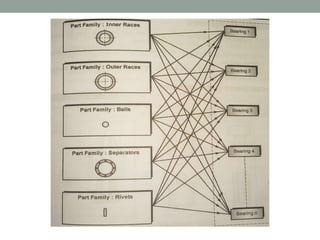

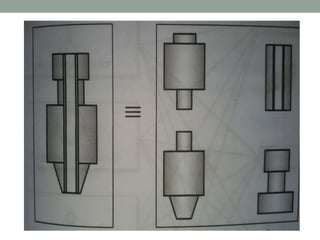

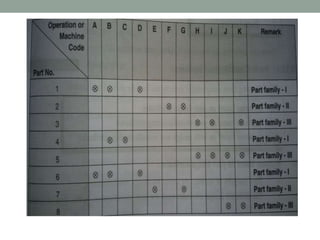

This document discusses group technology, which is a manufacturing philosophy that groups similar parts into families to take advantage of their design and manufacturing similarities. It defines part families as collections of parts that are similar geometrically or in their production steps. The document outlines four methods to group parts into families: visual inspection, composite part analysis, production flow analysis, and parts classification/coding. It also lists advantages like reduced setup times and disadvantages like difficulty in grouping parts.