This document discusses mechanical measurement and provides definitions and explanations of key concepts. It covers:

1) The need for mechanical measurement in control systems, research, quality control, and decision making.

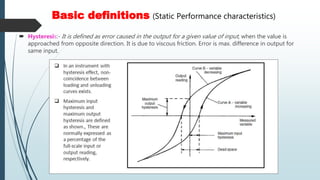

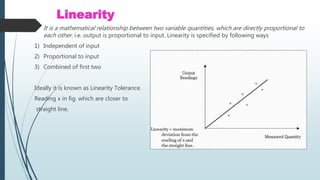

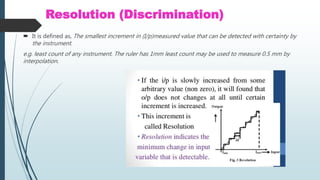

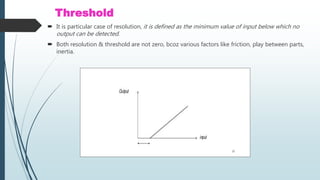

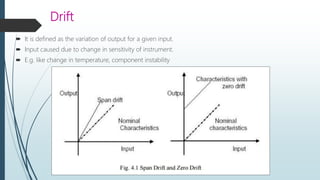

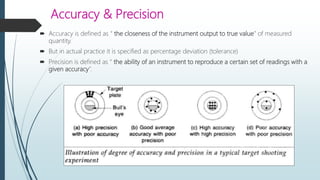

2) Definitions of static performance characteristics like hysteresis, linearity, resolution, threshold, drift, and zero stability.

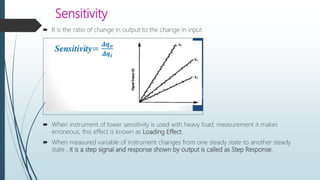

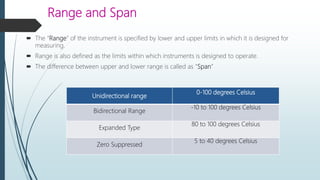

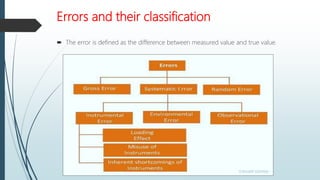

3) Explanations of sensitivity, accuracy, precision, range, span, dead band, and types of errors.

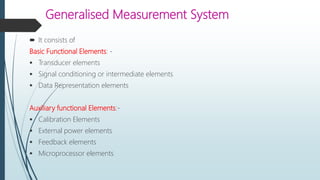

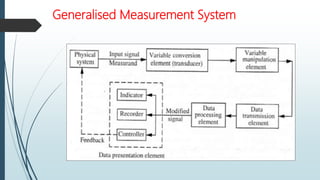

4) Descriptions of direct and indirect measurement methods and the general components of a measurement system.