Some key points made in the document include:

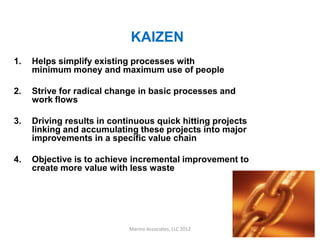

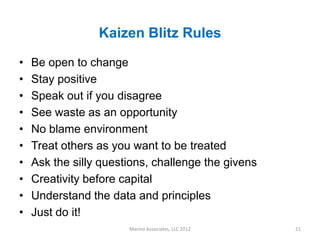

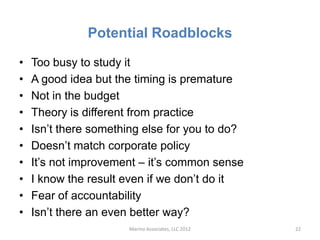

1. Kaizen aims to make incremental improvements to simplify processes and drive radical change through quick projects.

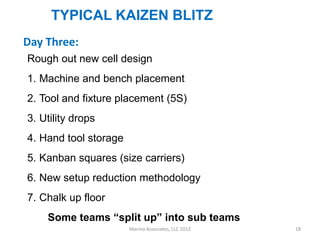

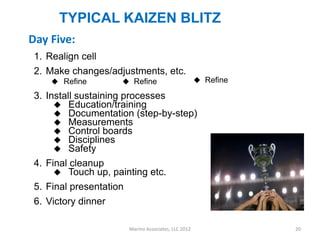

2. A Kaizen Blitz is a focused, short-term event (typically 5 days) to drive major improvements in a specific process.

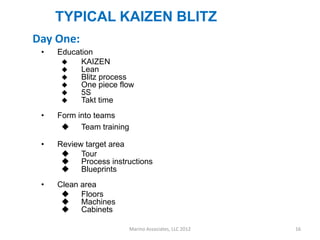

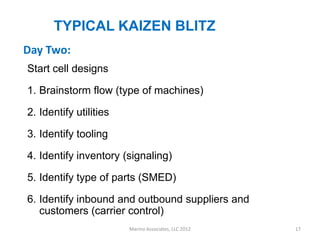

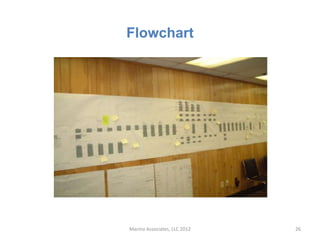

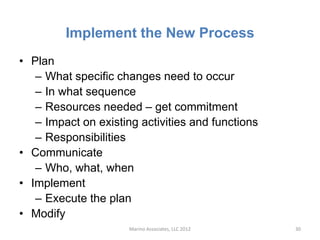

3. The Kaizen Blitz process involves forming a team, understanding the current process, designing and implementing the new process, and establishing controls to sustain improvements.