Tools and techniques of bpr

The document lists various tools and techniques used in business process reengineering (BPR), including purpose analysis, competitive comparison, process quality management, strategic capacity analysis, critical success factors analysis, change management techniques, process mapping, waste analysis, ownership analysis, benchmarking, product lifecycle analysis, Pareto analysis, segmentation, input/process/output diagrams, control systems design, measures of performance design, culture development, postponement analysis, impact/ease analysis, risk analysis, simulation, and several other techniques. Many of these techniques are taught in detail in training courses on BPR and related topics. However, innovative lateral thinking is also needed to achieve breakthrough improvements rather than just making current processes more efficient.

Recommended

Recommended

More Related Content

What's hot

What's hot (20)

Viewers also liked

Viewers also liked (8)

Similar to Tools and techniques of bpr

Similar to Tools and techniques of bpr (20)

Tools and techniques of bpr

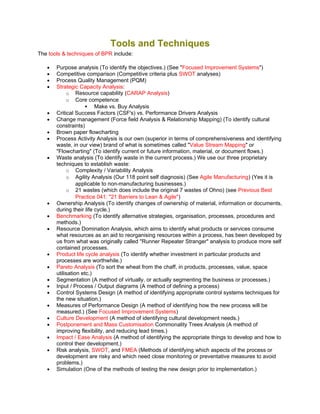

- 1. Tools and Techniques The tools & techniques of BPR include: • Purpose analysis (To identify the objectives.) (See "Focused Improvement Systems") • Competitive comparison (Competitive criteria plus SWOT analyses) • Process Quality Management (PQM) • Strategic Capacity Analysis: o Resource capability (CARAP Analysis) o Core competence Make vs. Buy Analysis • Critical Success Factors (CSF's) vs. Performance Drivers Analysis • Change management (Force field Analysis & Relationship Mapping) (To identify cultural constraints) • Brown paper flowcharting • Process Activity Analysis is our own (superior in terms of comprehensiveness and identifying waste, in our view) brand of what is sometimes called "Value Stream Mapping" or "Flowcharting" (To identify current or future information, material, or document flows.) • Waste analysis (To identify waste in the current process.) We use our three proprietary techniques to establish waste: o Complexity / Variability Analysis o Agility Analysis (Our 118 point self diagnosis) (See Agile Manufacturing) (Yes it is applicable to non-manufacturing businesses.) o 21 wastes (which does include the original 7 wastes of Ohno) (see Previous Best Practice 041: "21 Barriers to Lean & Agile") • Ownership Analysis (To identify changes of ownership of material, information or documents, during their life cycle.) • Benchmarking (To identify alternative strategies, organisation, processes, procedures and methods.) • Resource Domination Analysis, which aims to identify what products or services consume what resources as an aid to reorganising resources within a process, has been developed by us from what was originally called "Runner Repeater Stranger" analysis to produce more self contained processes. • Product life cycle analysis (To identify whether investment in particular products and processes are worthwhile.) • Pareto Analysis (To sort the wheat from the chaff, in products, processes, value, space utilisation etc.) • Segmentation (A method of virtually, or actually segmenting the business or processes.) • Input / Process / Output diagrams (A method of defining a process) • Control Systems Design (A method of identifying appropriate control systems techniques for the new situation.) • Measures of Performance Design (A method of identifying how the new process will be measured.) (See Focused Improvement Systems) • Culture Development (A method of identifying cultural development needs.) • Postponement and Mass Customisation Commonality Trees Analysis (A method of improving flexibility, and reducing lead times.) • Impact / Ease Analysis (A method of identifying the appropriate things to develop and how to control their development.) • Risk analysis, SWOT, and FMEA (Methods of identifying which aspects of the process or development are risky and which need close monitoring or preventative measures to avoid problems.) • Simulation (One of the methods of testing the new design prior to implementation.)

- 2. We teach most of these techniques in detail in our S02 Business Process Reengineering training & others in detail in a number of our other courses (See below). However a significant innovative input is required to avoid this process simply making the present process more efficient instead of more effective. This is provided by Blue Skies (breakthrough) lateral thinking.