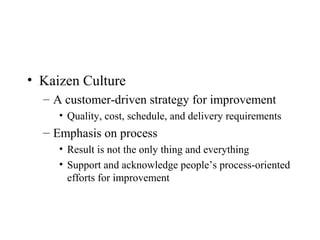

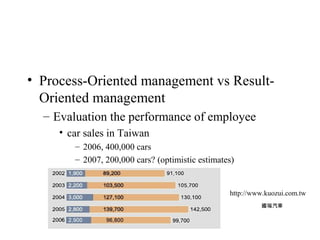

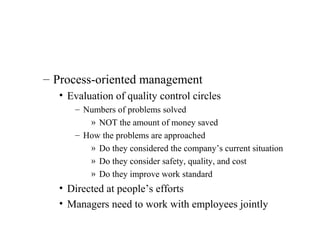

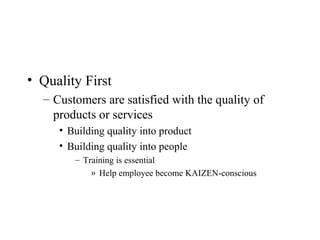

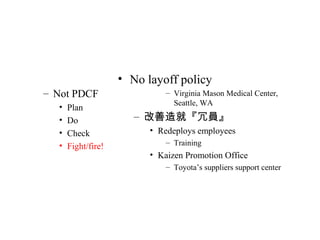

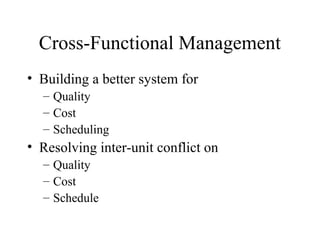

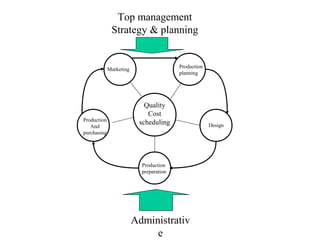

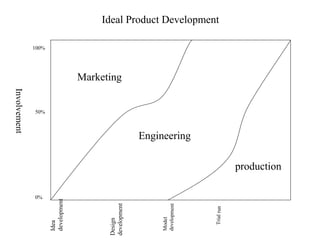

Kaizen refers to ongoing improvement involving everyone in an organization. It emphasizes a culture of supporting quality improvement through problem solving over the use of specific tools. The philosophy and systems behind the Japanese quality movement center around Kaizen. Process-oriented thinking and continuous incremental improvement differ from Western result-oriented and innovation-focused management. Key aspects of Kaizen culture include adopting a customer-driven and collaborative approach to cross-functional problem solving.