1. Geotextiles are permeable geosynthetics made solely of textiles that are used in geotechnical engineering and construction as an integral part of structures and systems. They serve separation, reinforcement, filtration, drainage, and sealing functions.

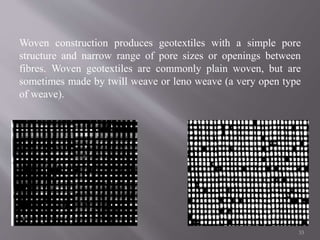

2. Geotextiles can be woven or nonwoven. Woven geotextiles have high strength in two directions and low elongation, while nonwoven geotextiles are thicker and have a felt-like structure formed through needle-punching, heat-bonding, resin-bonding, or a combination of methods.

3. Geotextiles are used widely in construction applications such as roads, railways, drainage systems