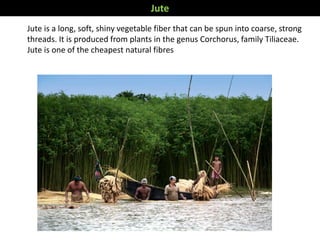

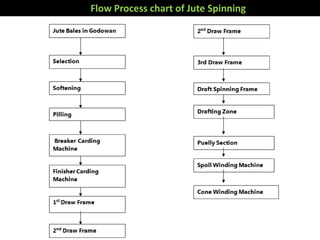

The document provides information on the process of manufacturing jute yarn. It begins with an overview of jute fiber characteristics and proceeds to describe the steps in detail:

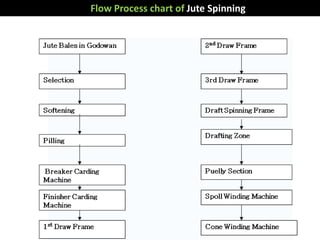

1) Raw jute bales are brought to jute mills and stored.

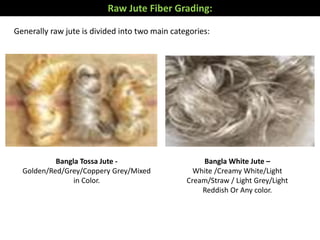

2) The bales are graded and a batch is selected based on fiber properties and desired yarn quality.

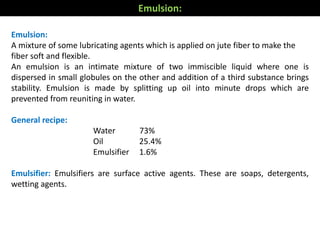

3) An emulsion is prepared using water, oil, and emulsifier to soften the fibers.

4) The fibers pass through softening machines with spiraled rollers where emulsion is applied to make them flexible for spinning.