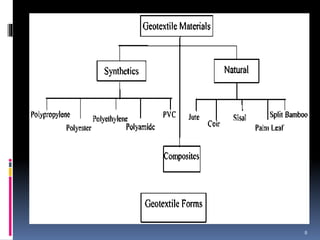

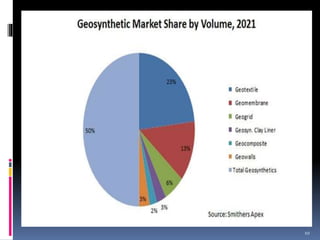

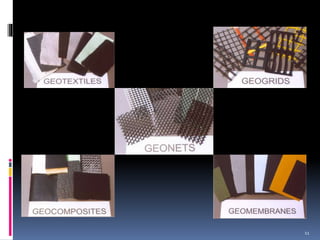

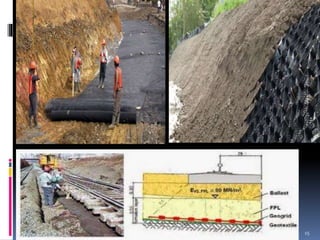

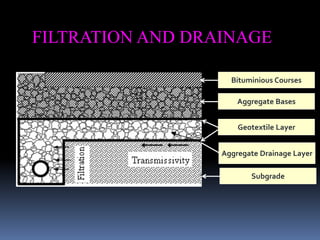

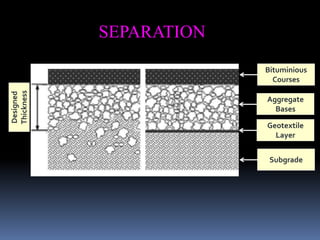

The document discusses reinforced soil and geosynthetics. It begins with an introduction that defines geosynthetics as manufactured polymer products used in geotechnical engineering works. Soil reinforcement using geosynthetics improves strength through lateral restraint between the geosynthetic and soil, forcing failure planes deeper, and supporting wheel loads. The document then discusses various types of geosynthetics like geotextiles, geogrids, and geomembranes. It provides examples of using geosynthetics for filtration, drainage, separation, and reinforcement of slopes, retaining walls, and embankments. The advantages include easier installation and higher strength compared to traditional methods.