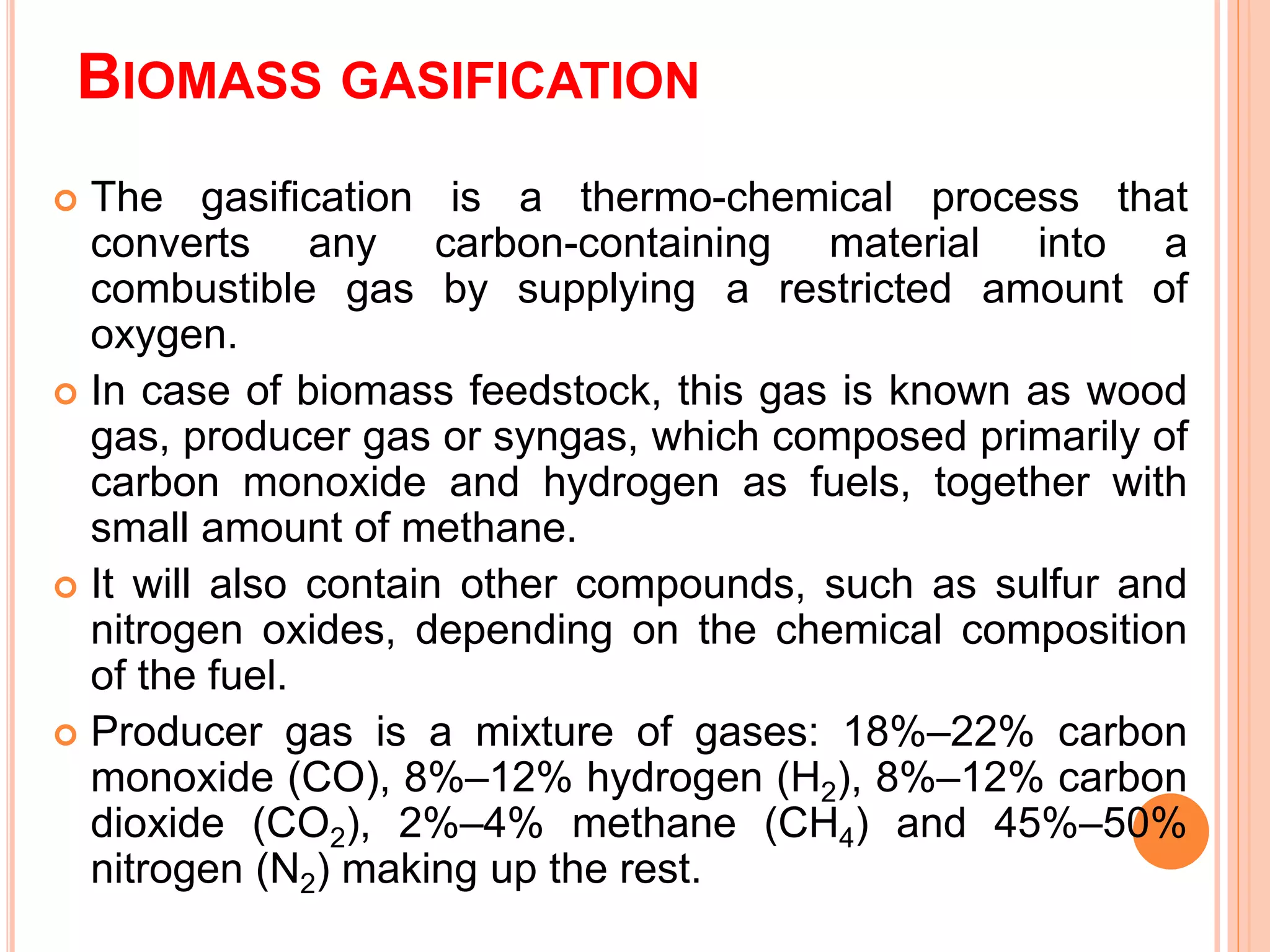

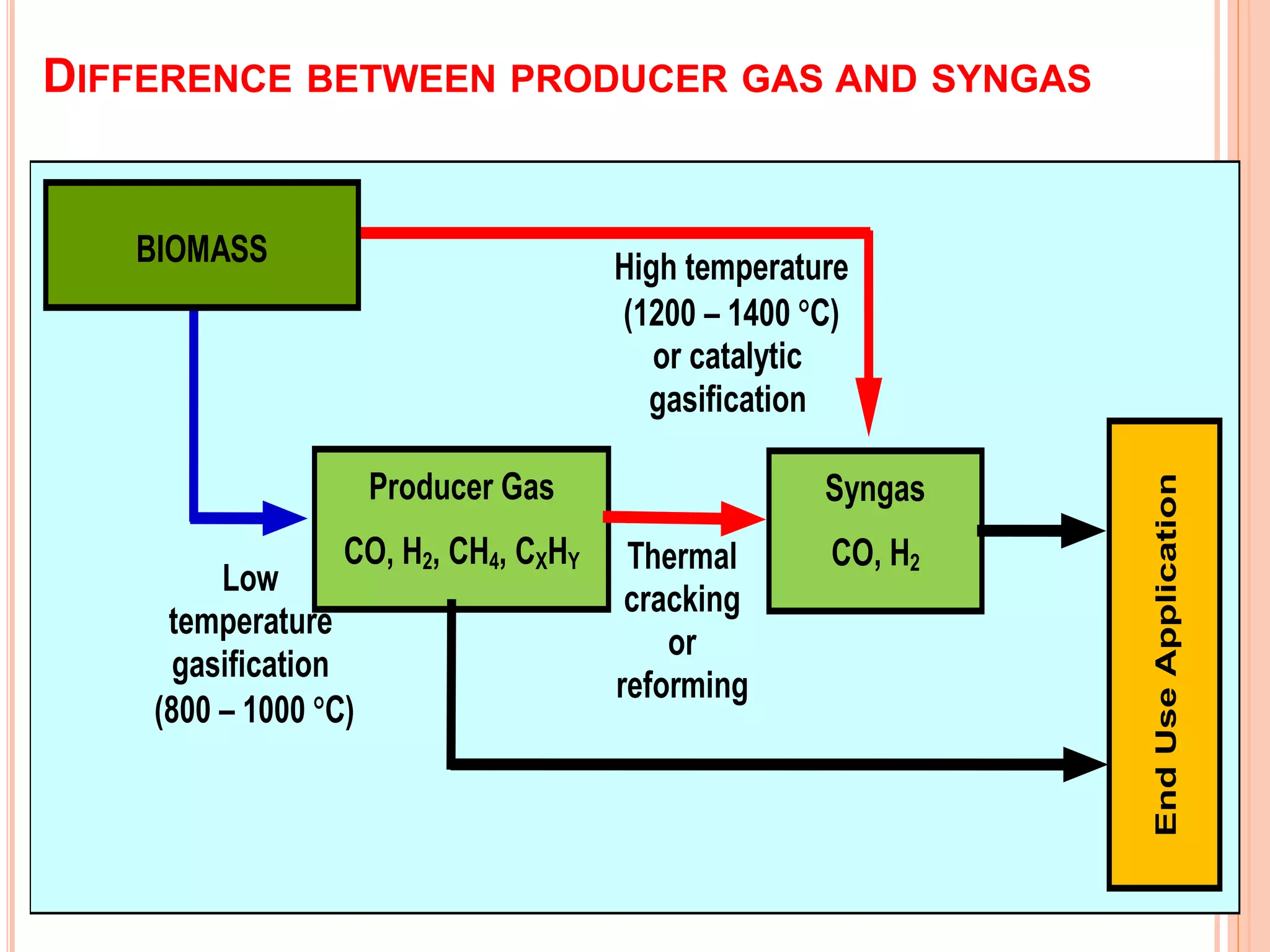

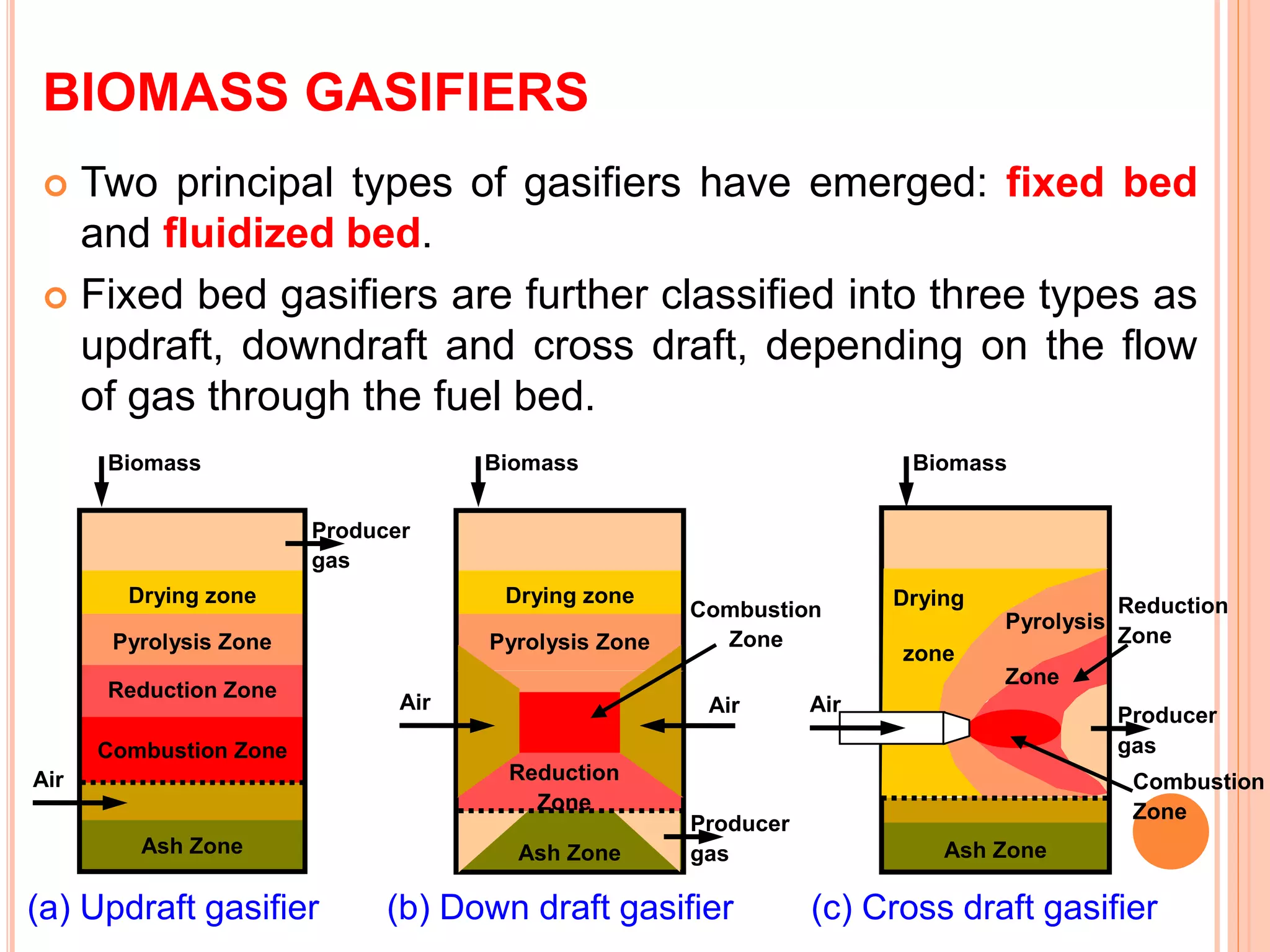

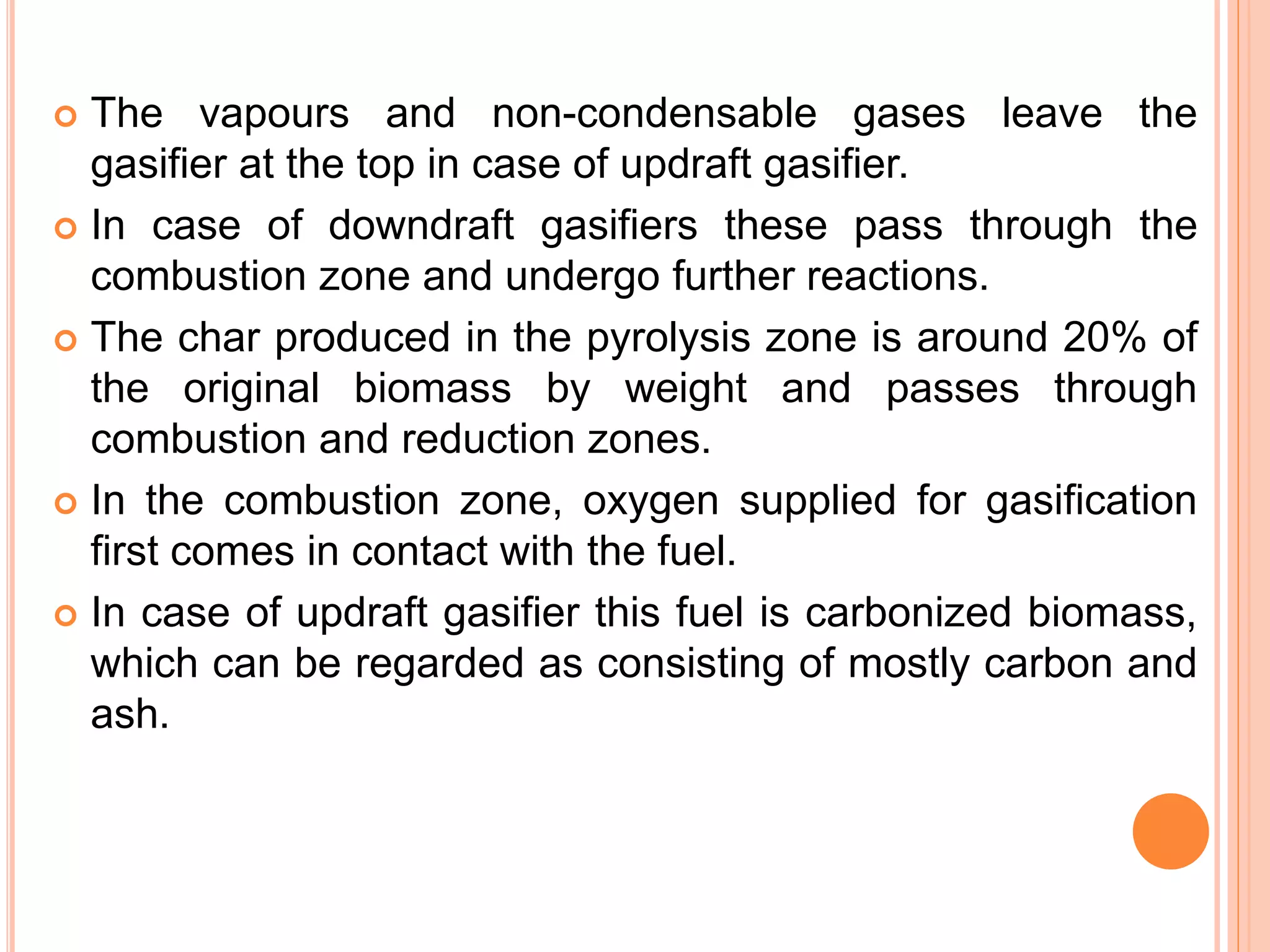

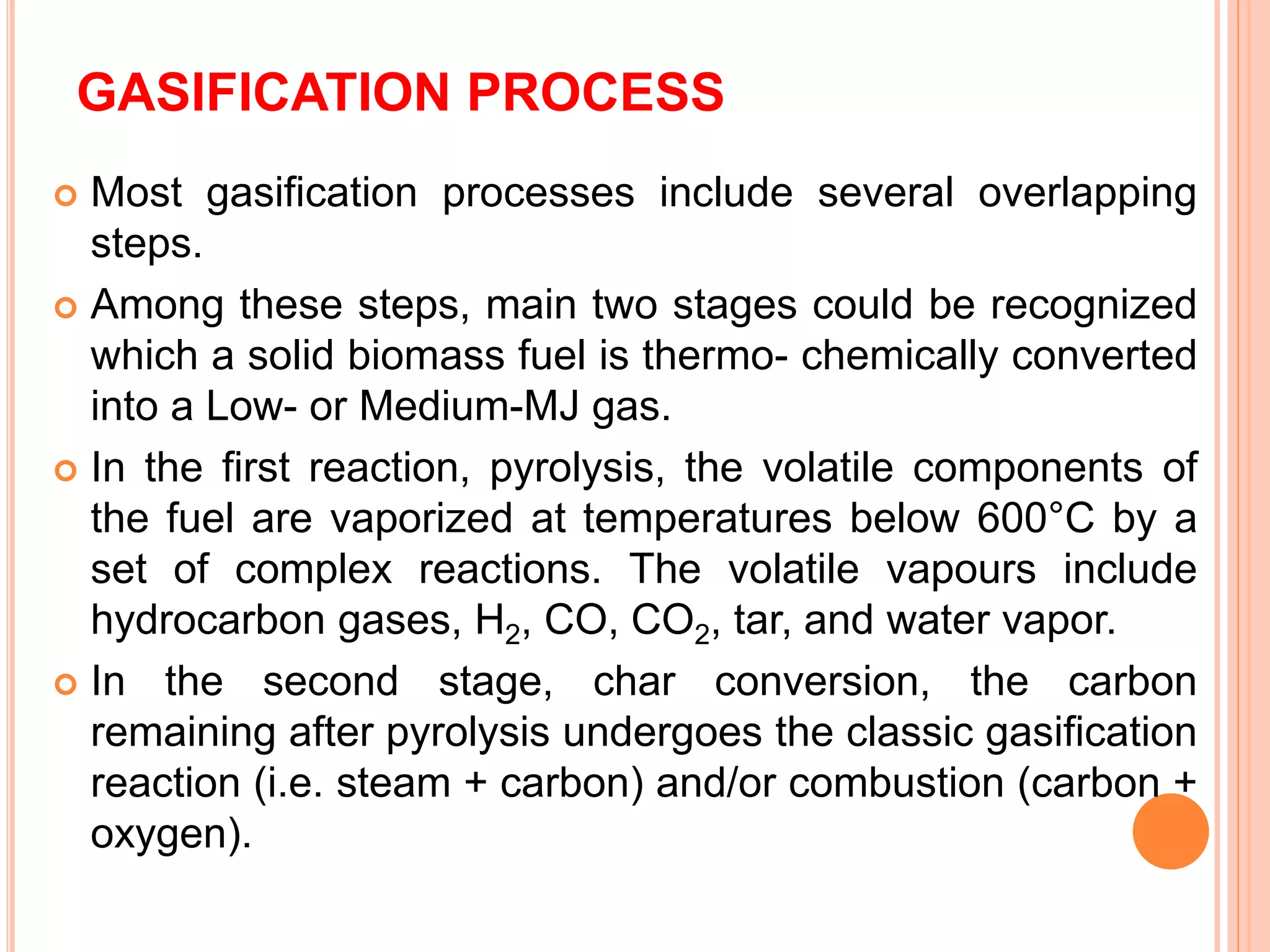

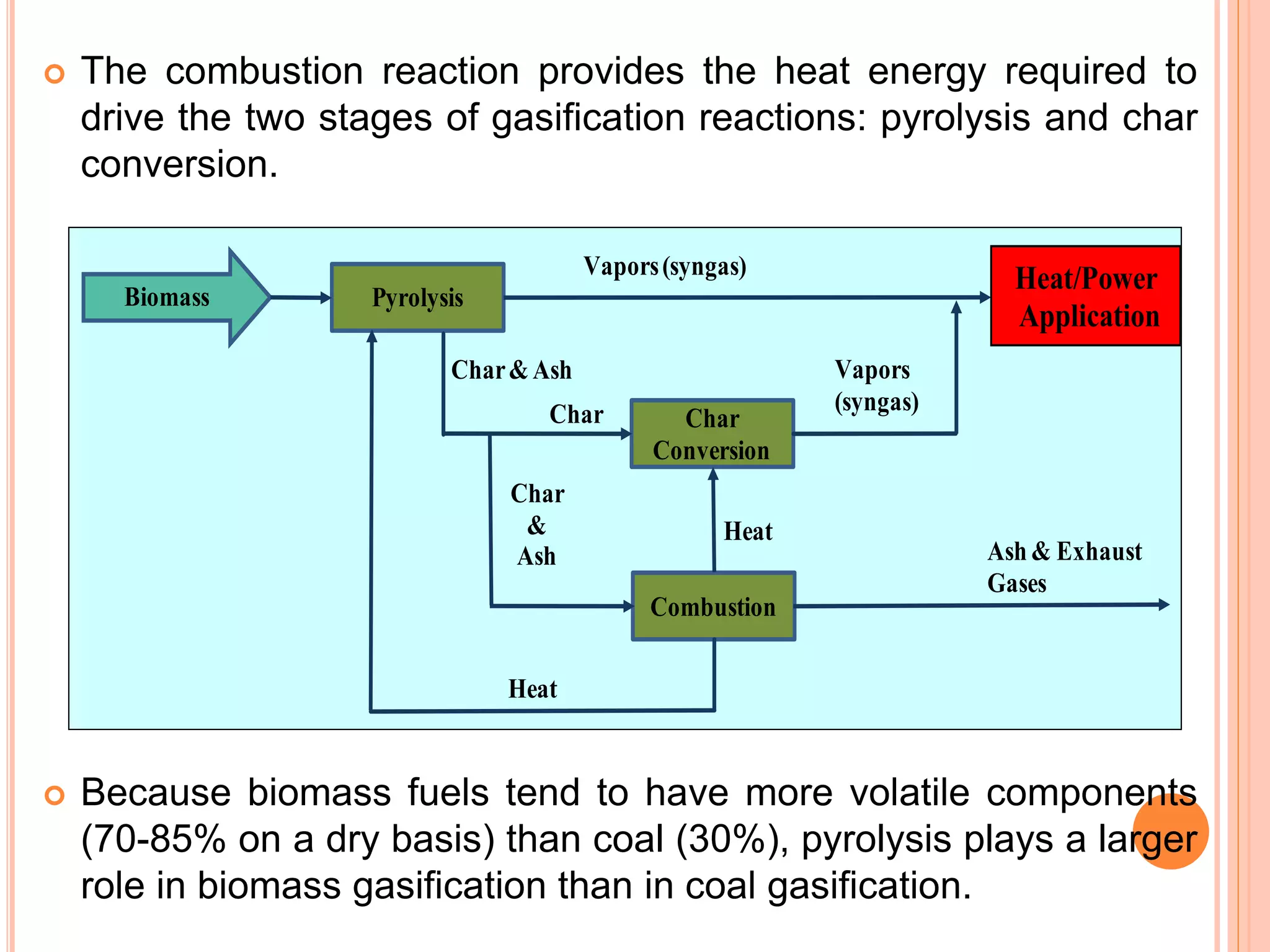

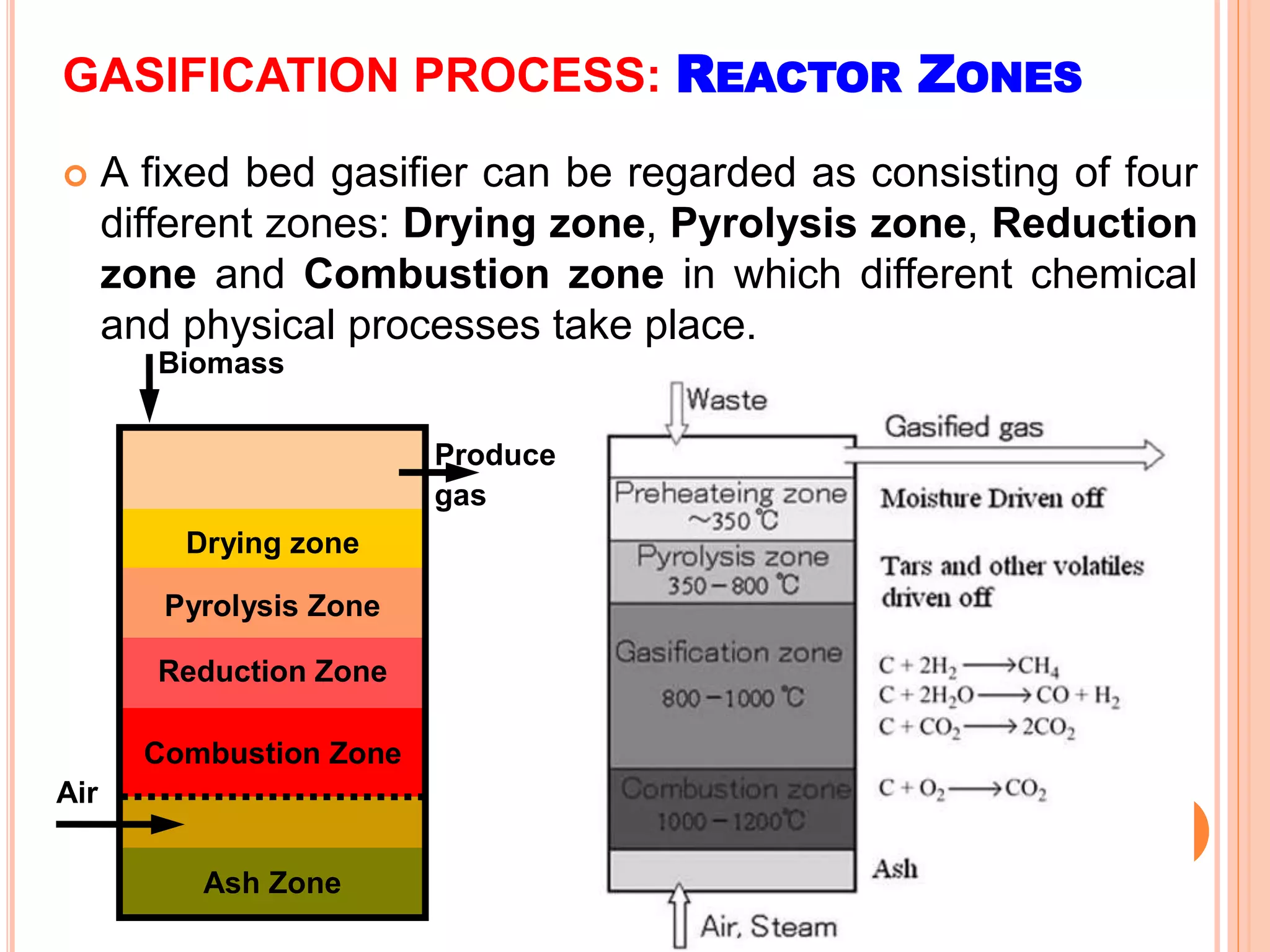

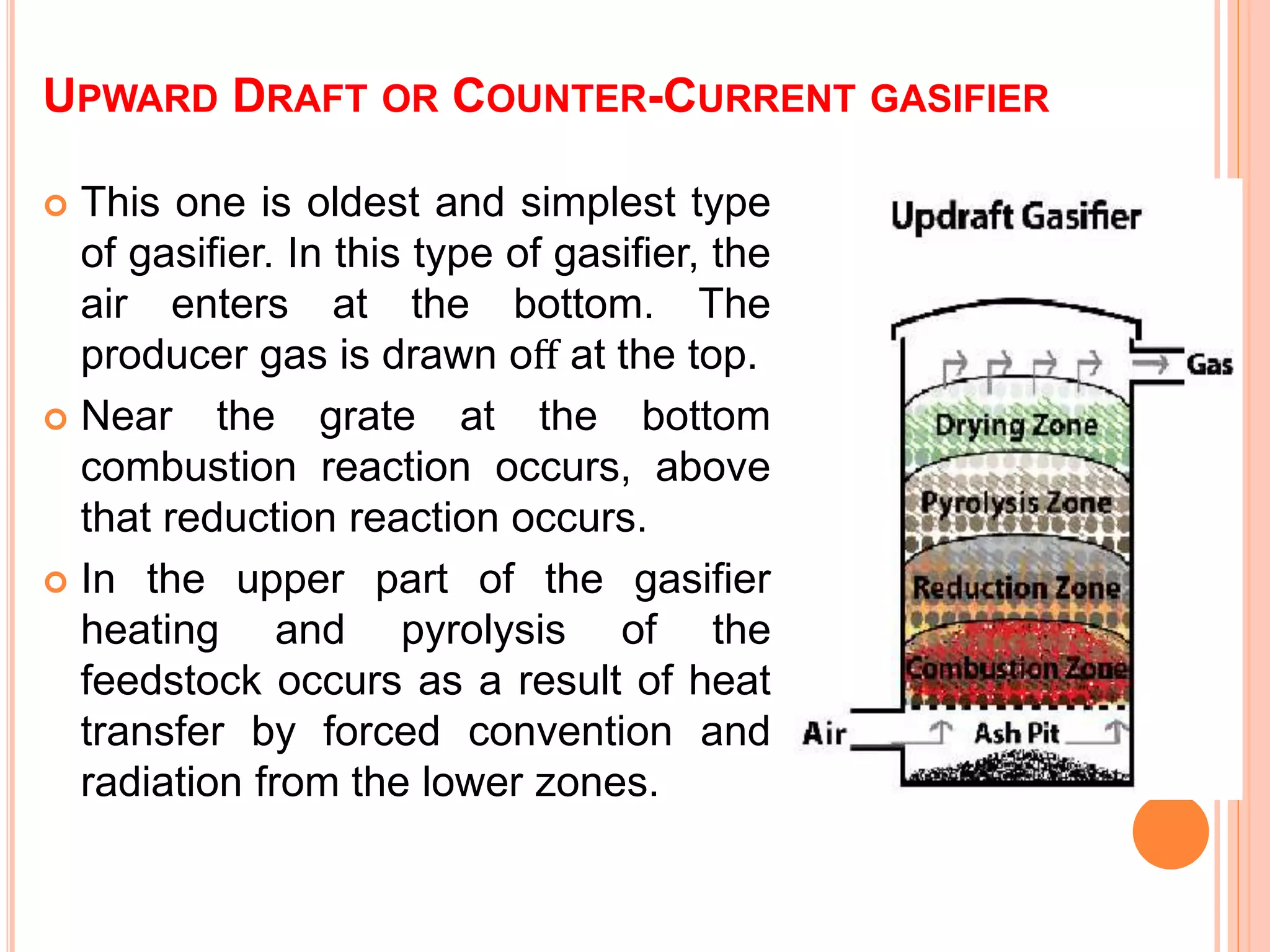

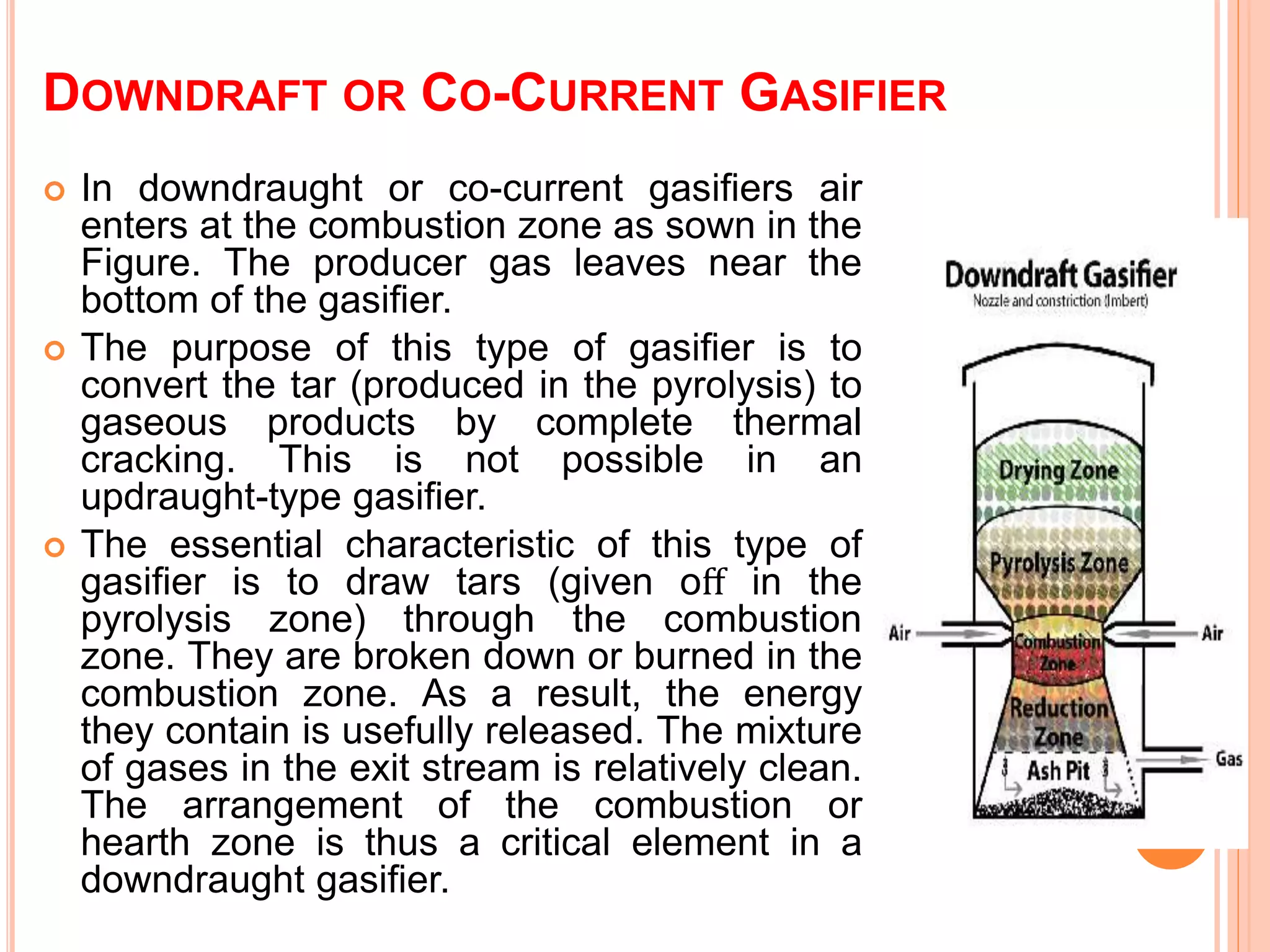

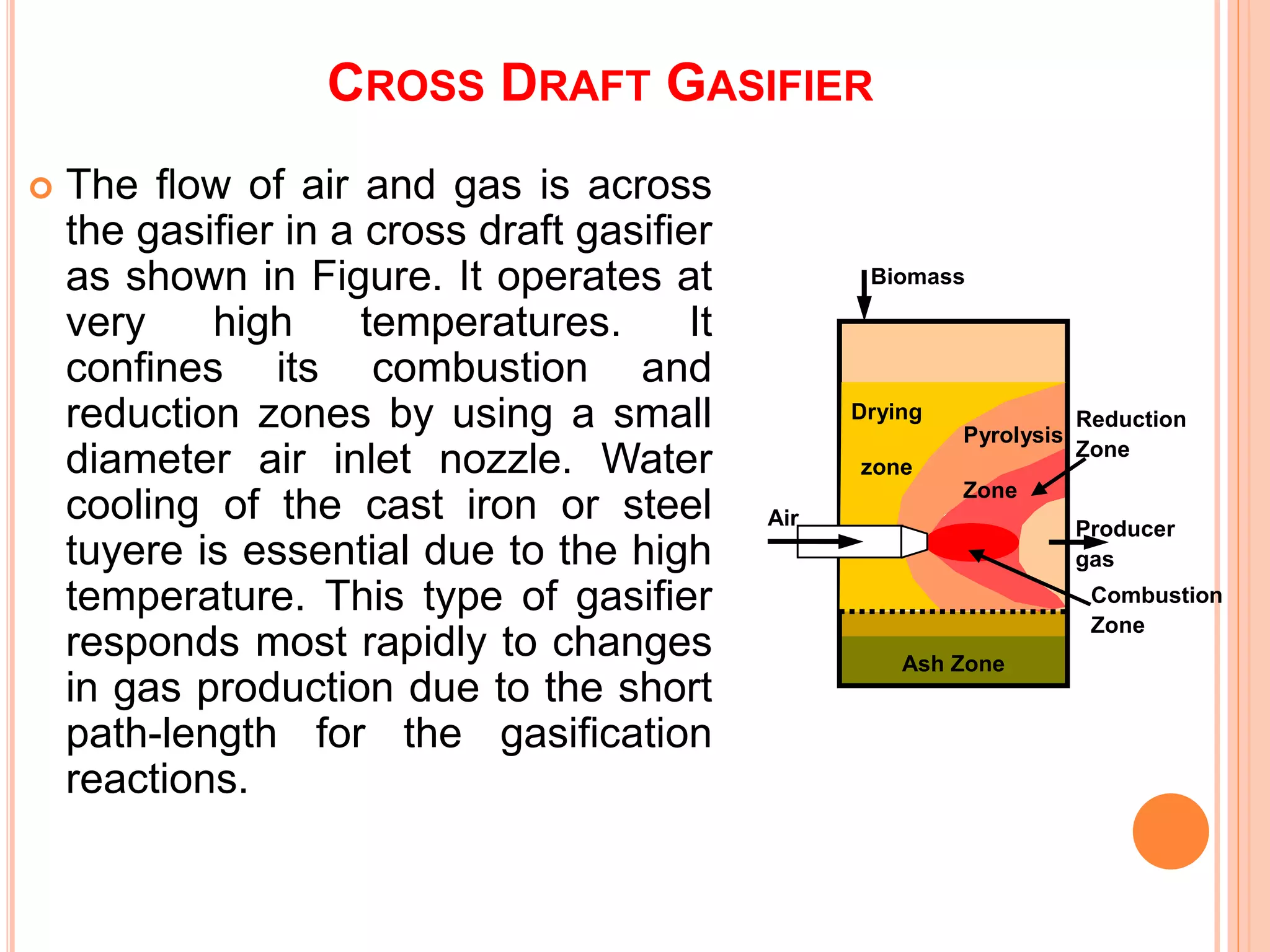

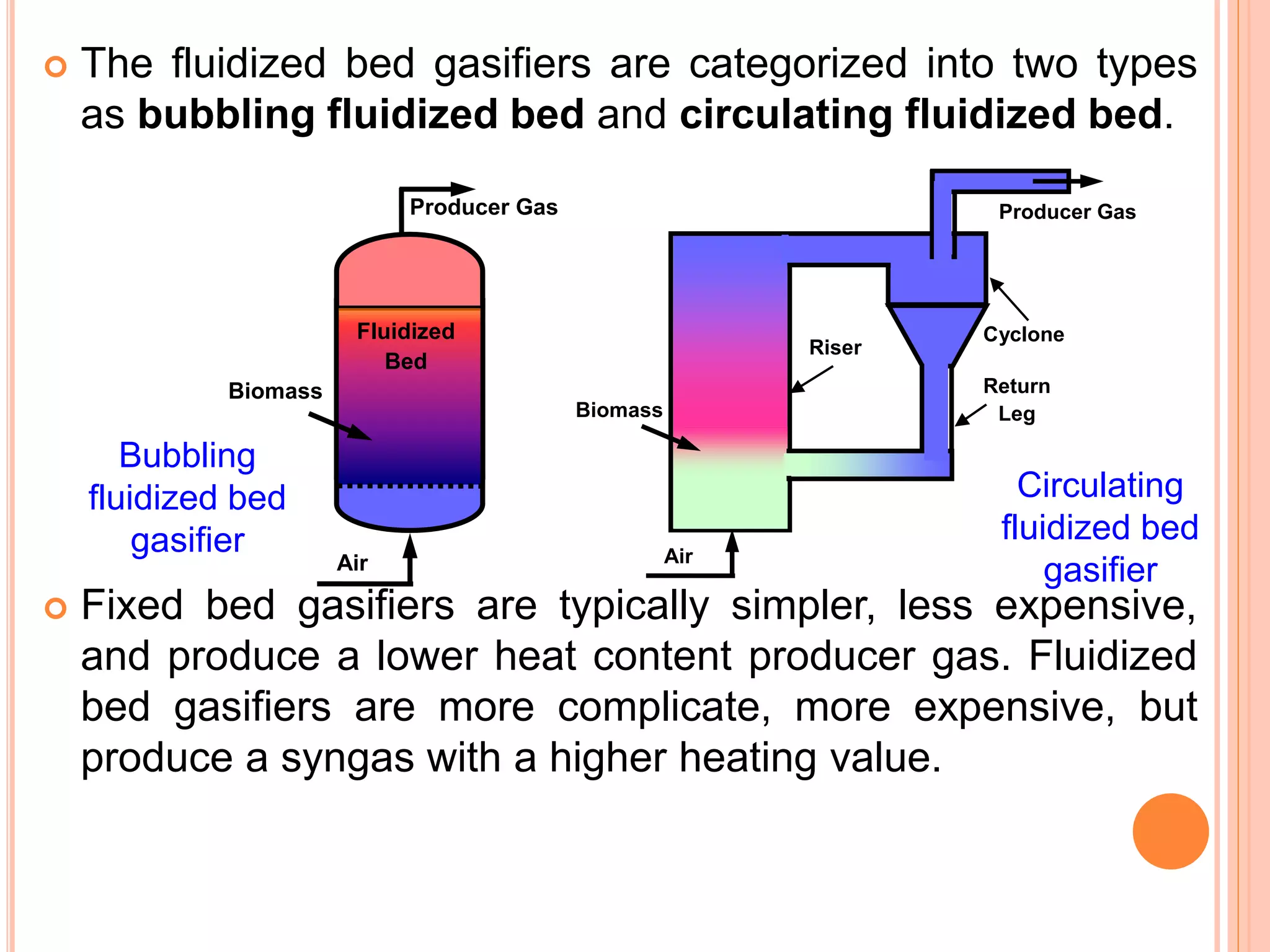

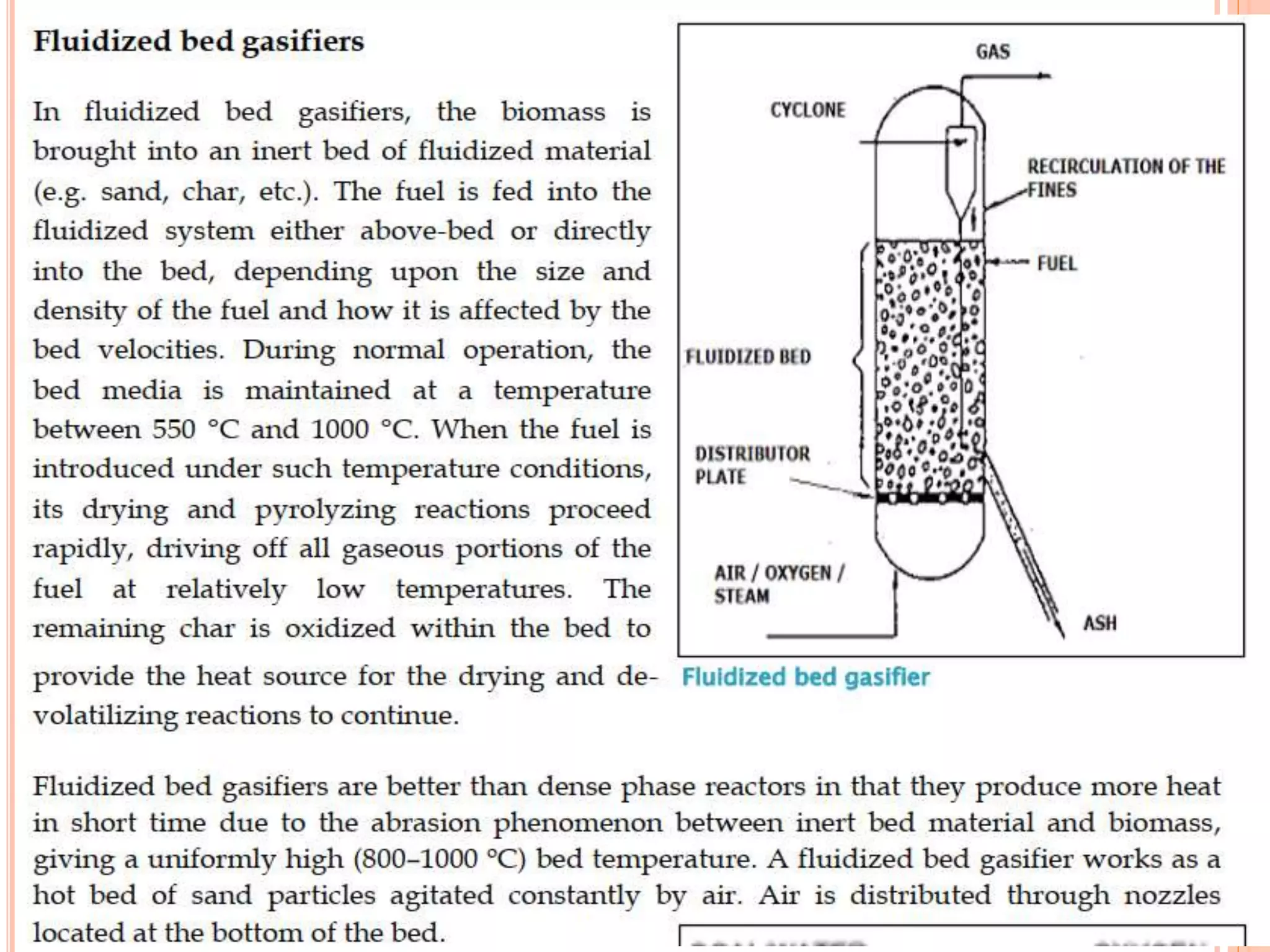

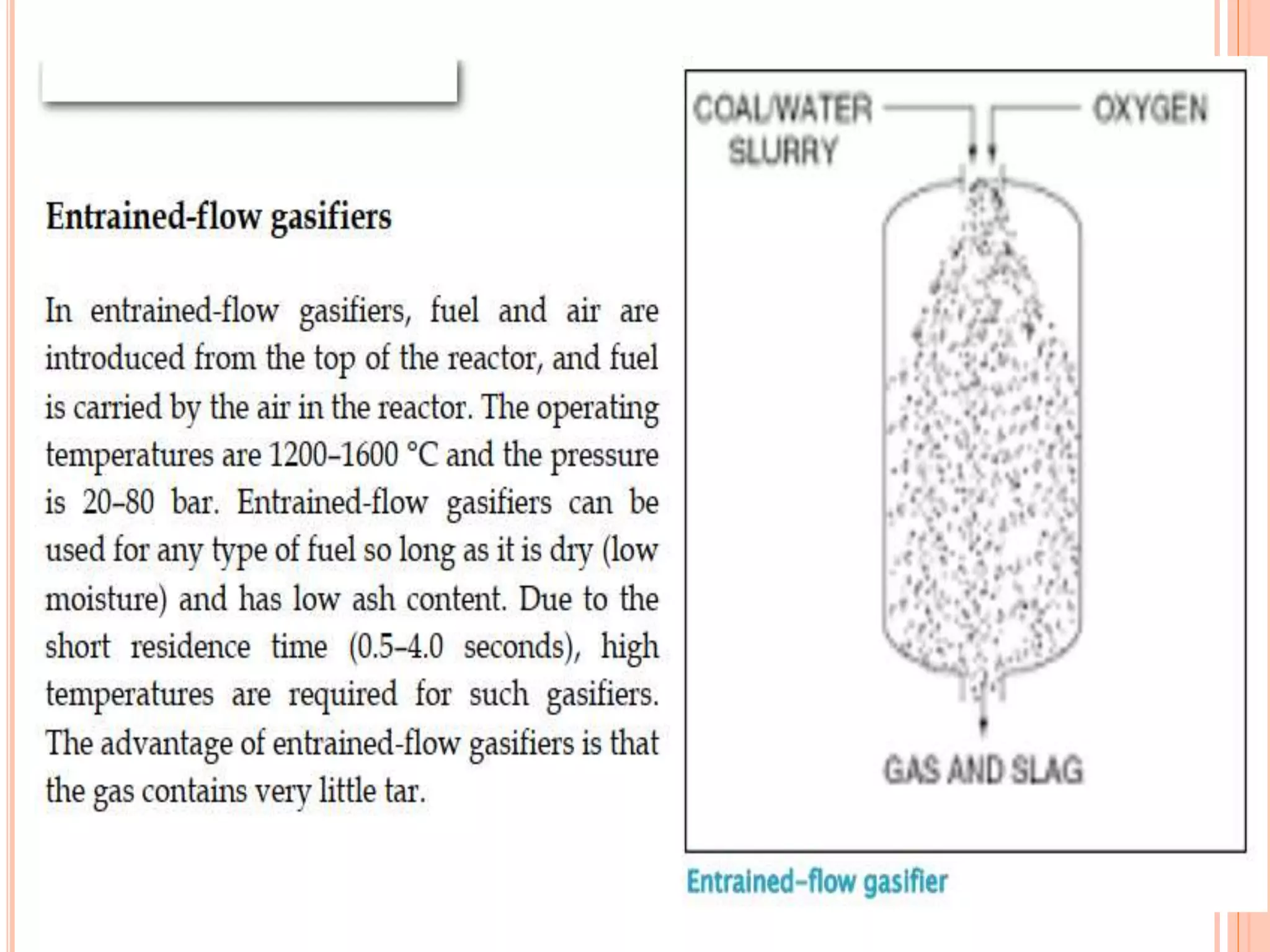

The document discusses biomass gasification and different types of gasifiers. Gasification is a process that converts carbonaceous materials into a combustible gas. There are two main types of gasification gases - producer gas produced at low temperatures, and syngas produced at high temperatures. Fixed bed gasifiers like updraft, downdraft and crossdraft gasifiers as well as fluidized bed gasifiers are described. Producer gas contains more hydrocarbons while syngas contains mainly CO and H2. The applications and advantages of biomass gasification are also summarized.