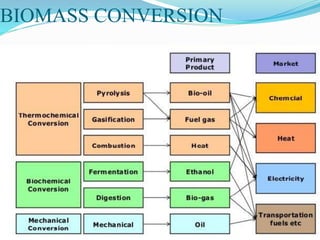

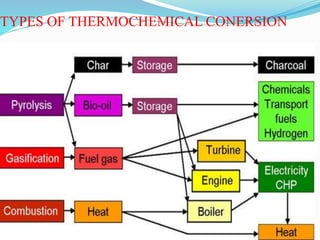

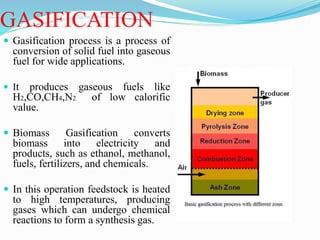

Thermochemical conversion of biomass involves processes that use heat to convert biomass into other forms. This includes combustion, gasification, and pyrolysis. Gasification converts biomass into a gaseous fuel called producer gas through a series of chemical reactions at high temperatures. It has advantages like efficiency and being carbon neutral, but requires precise control and feedstock preparation. Pyrolysis thermally decomposes biomass into solid, liquid, and gaseous products depending on temperature and residence time.