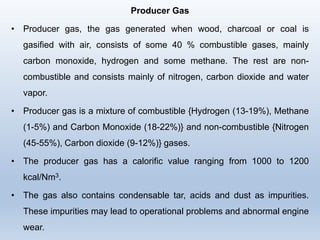

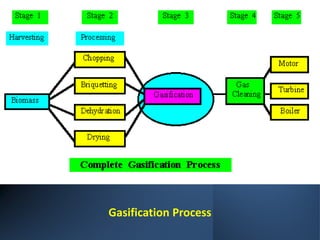

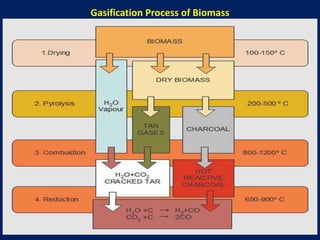

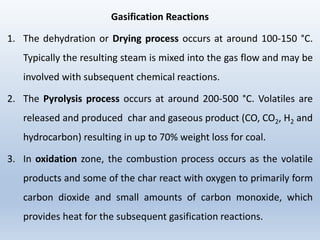

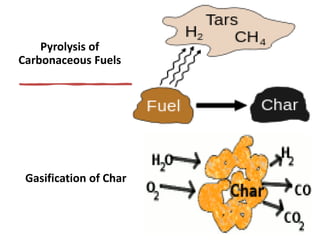

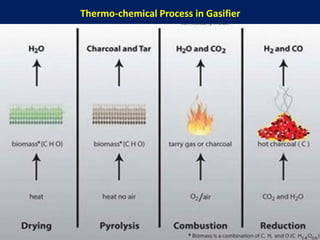

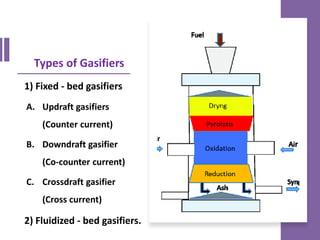

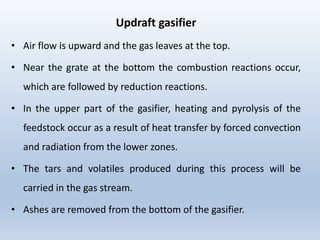

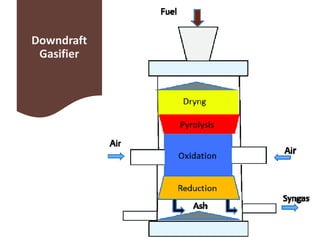

This document discusses principles of gasification and different types of gasifiers. Gasification involves partially oxidizing biomass at high temperatures to produce a gaseous fuel called producer gas. Producer gas consists mainly of combustible gases like carbon monoxide, hydrogen and methane, as well as non-combustible gases like nitrogen, carbon dioxide and water vapor. Several factors affect gasification including biomass properties and moisture content. Common types of gasifiers include updraft, downdraft, crossdraft, and fluidized bed gasifiers. Updraft gasifiers have high efficiency but produce tarry gas, while downdraft and crossdraft gasifiers produce tar-free gas but with lower efficiency. Fluidized bed gasifiers allow