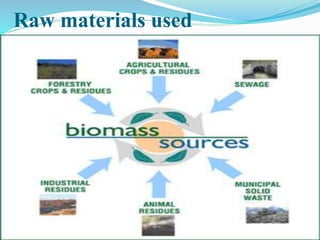

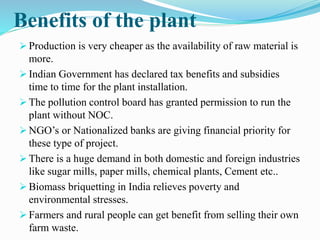

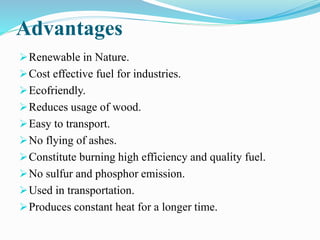

This document discusses biomass briquettes as an alternative energy source. Biomass briquettes are made through densifying agricultural and biomass waste using various machines. They can be used as fuel in industries like brick kilns, paper mills, and food processing. Setting up a biomass briquetting plant provides benefits like cheaper production costs due to abundant raw materials, tax benefits from the government, and high demand from industries. It is a renewable source of energy that can help reduce pollution and poverty.