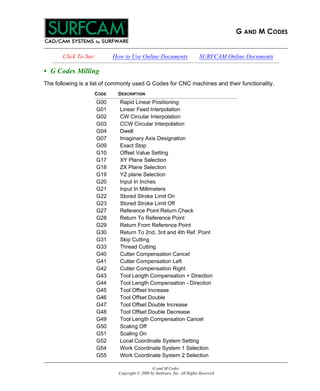

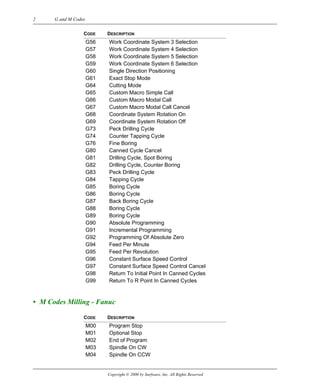

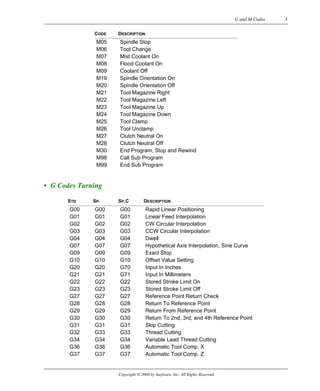

This document provides lists of commonly used G and M codes for CNC milling machines and turning centers. It includes over 50 G codes for functions like linear and circular interpolation, coordinate system selection, canned cycles, and more. It also lists over 20 M codes for functions like program stop, spindle control, coolant control, and calling subprograms. The document serves as a reference for the standard G and M code functions for CNC machining.