The document provides information on lathe machine operations including:

- The principle of a lathe machine is that the workpiece rotates while the tool remains stationary, and material is removed in the form of chips as feed is applied to the tool.

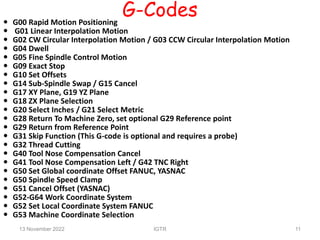

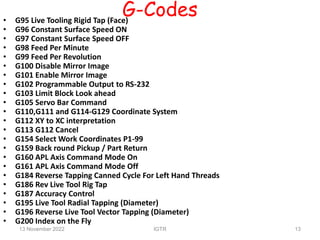

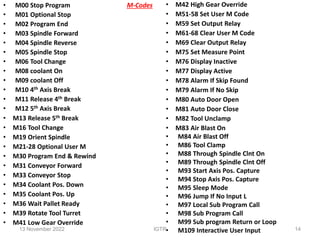

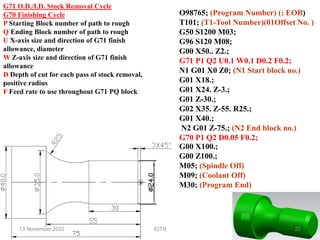

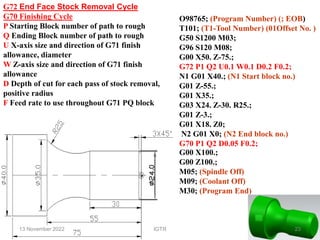

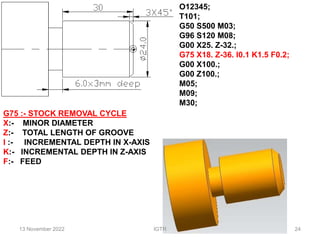

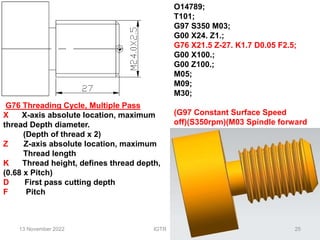

- G-codes and M-codes are listed that control lathe machine functions like spindle control, feed rates, tool changes, canned cycles for operations like drilling and threading.

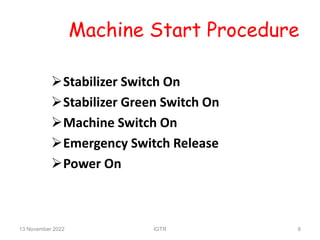

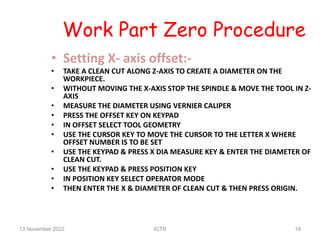

- Examples of specific canned cycles are provided, including G71 for roughing, G72 for end facing, G75 for grooving, and G76 for threading. Safety warnings and procedures for machine start up, tool and work offsets, and program runs are also outlined.