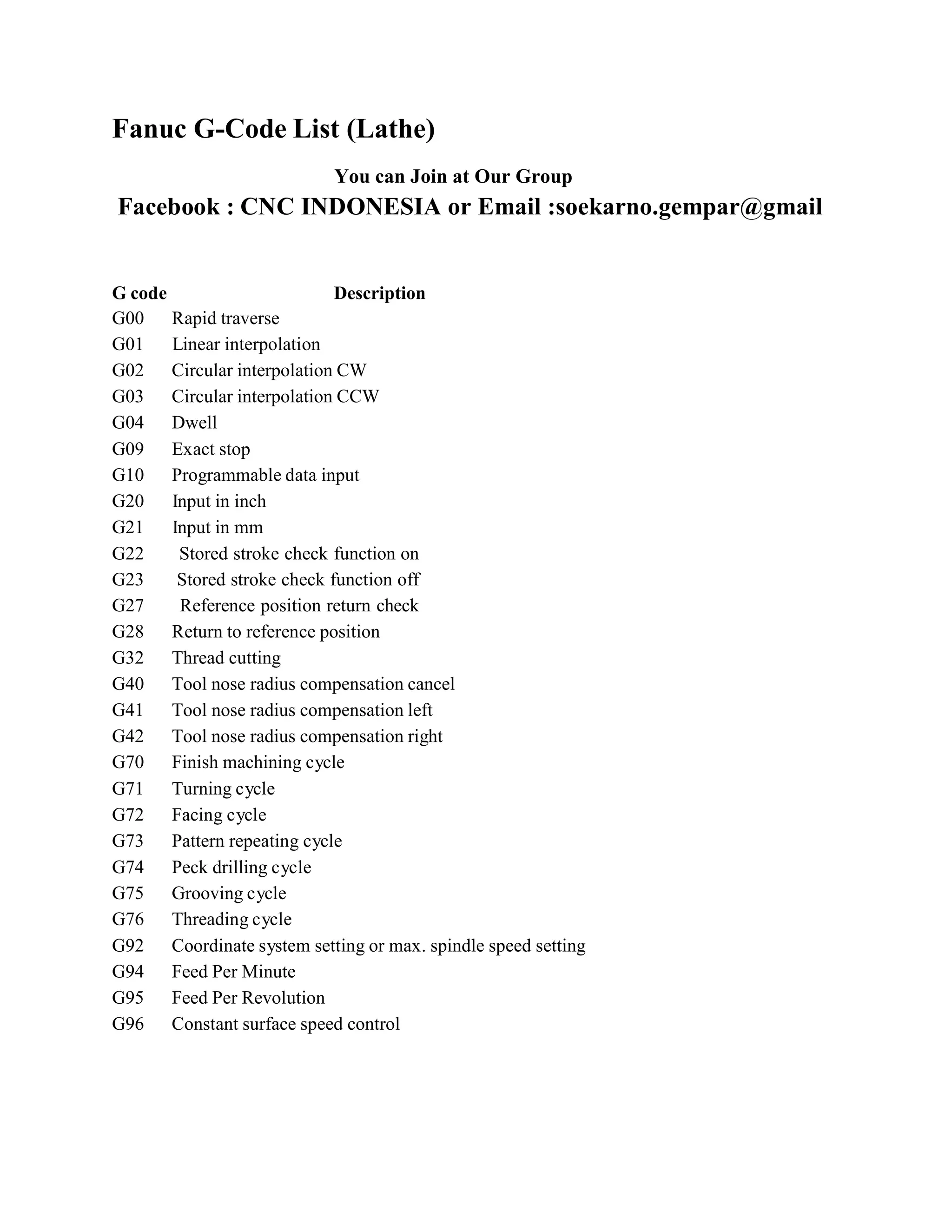

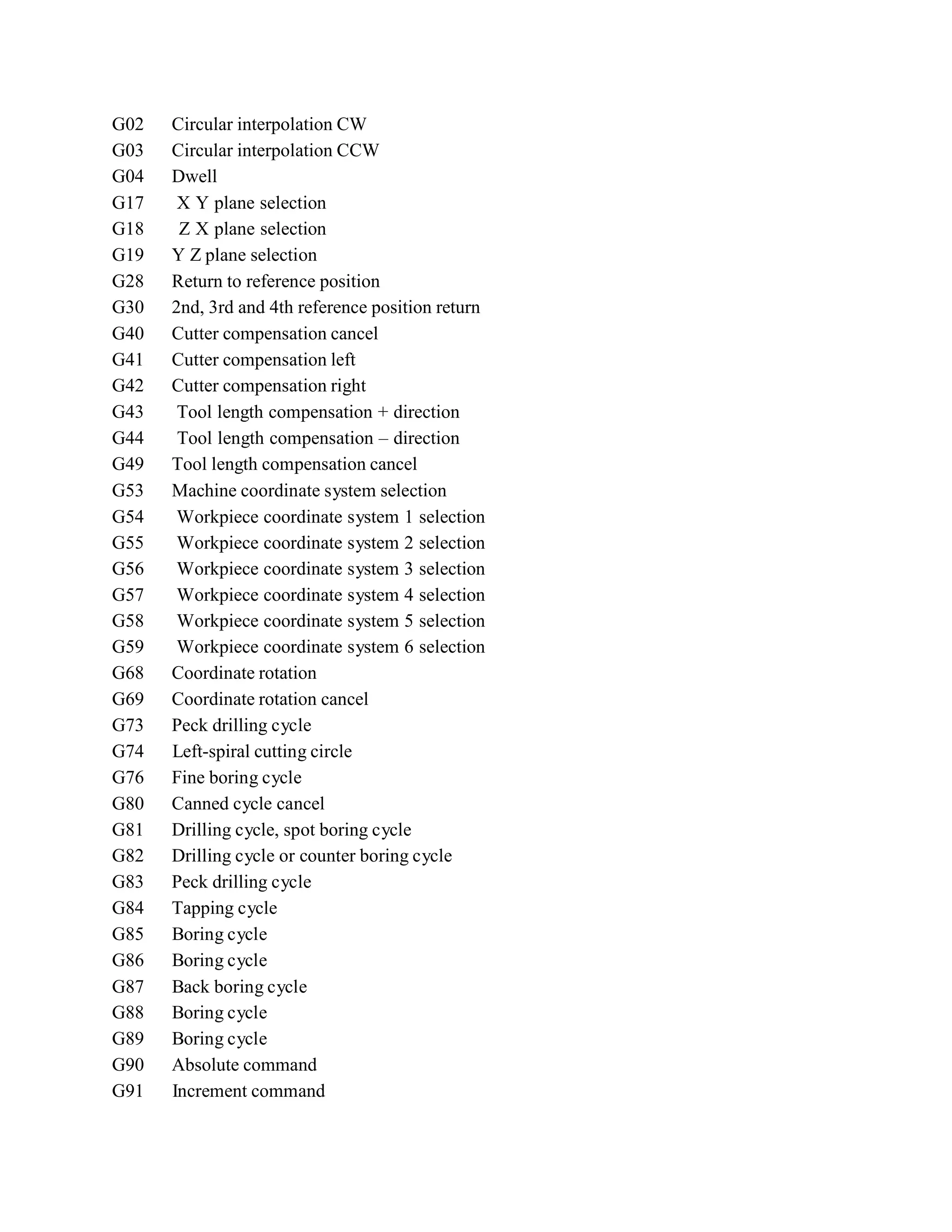

The document provides a comprehensive list of G-code commands for both lathe and mill operations used in CNC programming. It includes descriptions for various commands such as rapid traverse, linear interpolation, and different cycles for machining processes. Additionally, it offers details on coordinate system selections and tool compensation commands.