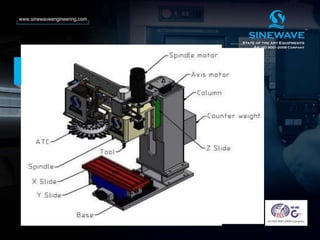

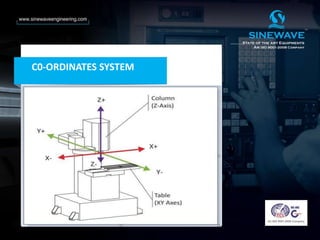

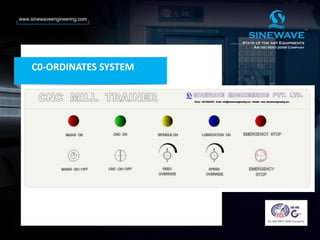

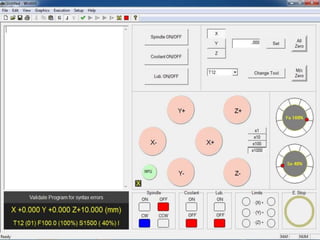

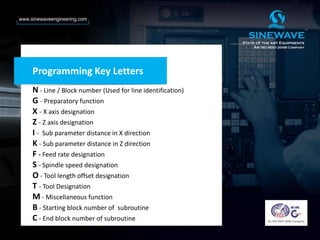

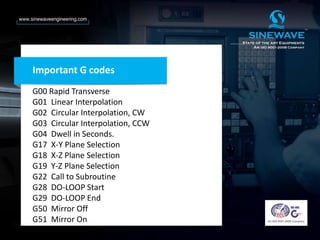

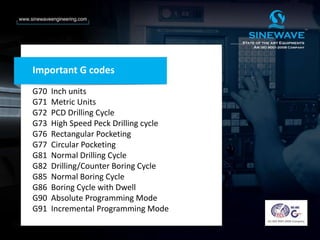

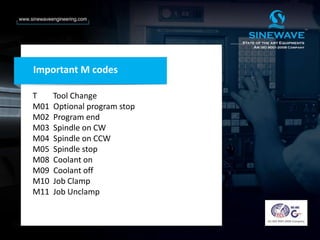

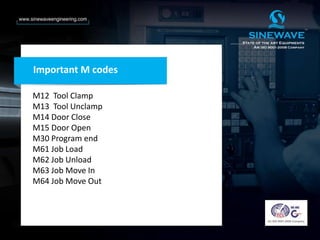

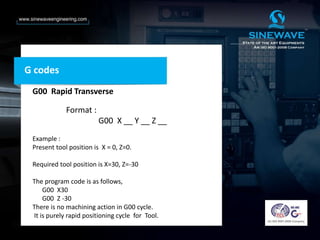

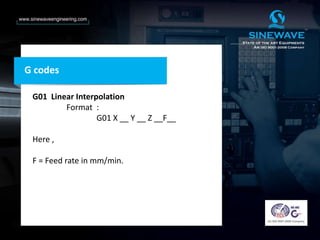

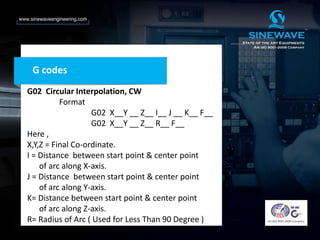

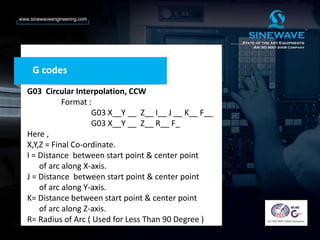

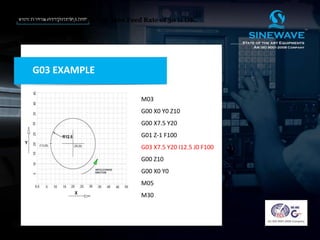

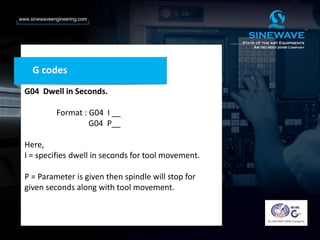

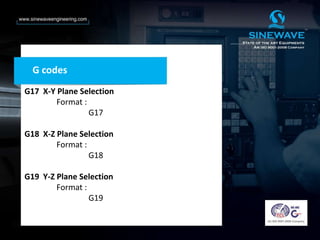

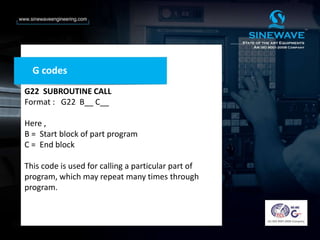

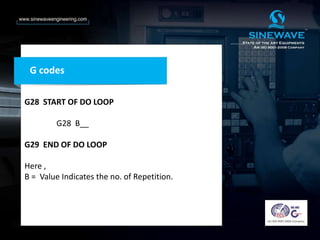

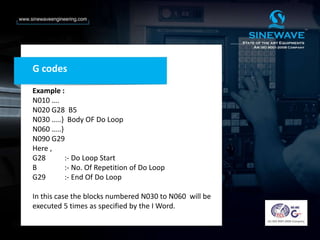

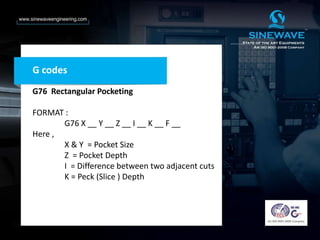

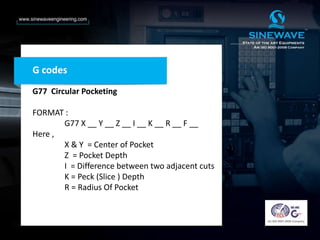

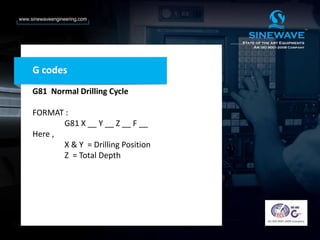

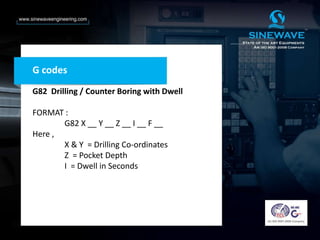

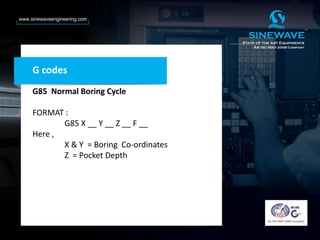

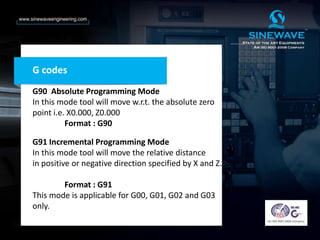

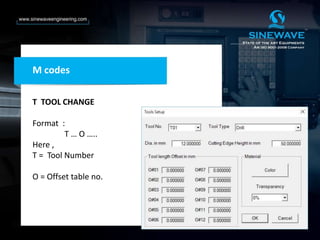

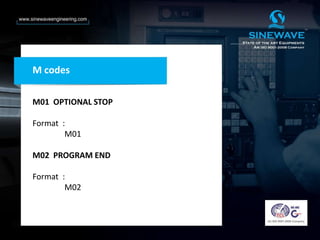

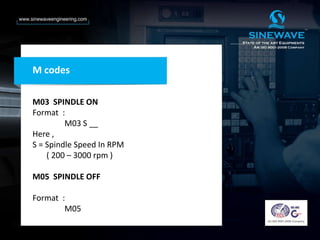

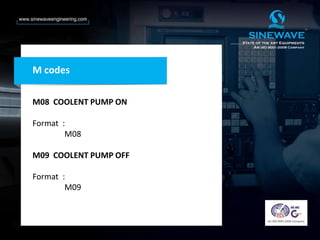

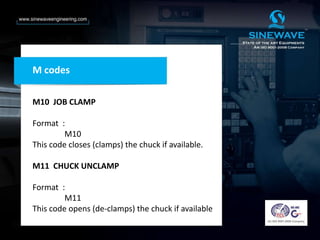

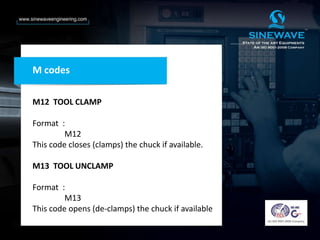

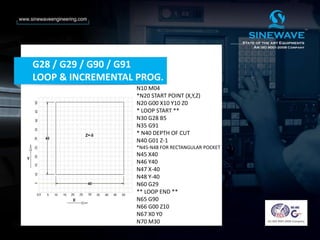

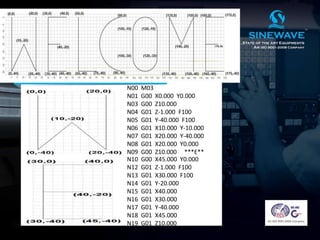

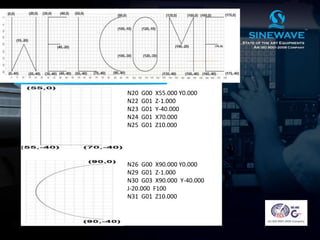

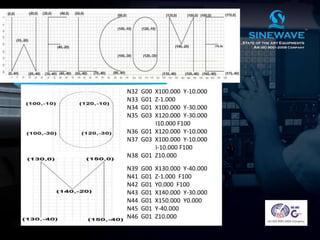

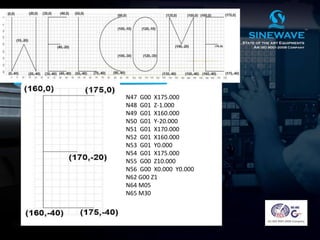

This document provides an overview of CNC milling machine programming. It introduces coordinate systems, important G and M codes for functions like linear interpolation, circular interpolation, drilling cycles, tool changes, and coolant control. Example programs are also included to demonstrate programming techniques like loops, mirroring, and subroutines.