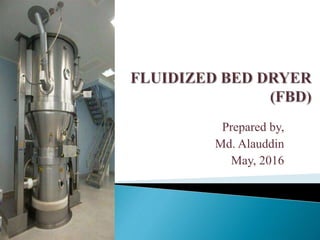

Fluidized bed drying is widely used for drying pharmaceutical powders and granules. It allows for direct contact between particles and heated air or gas, resulting in uniform and efficient drying. Hot air is passed through the granules in a perforated container, lifting the granules and suspending them in the air stream. This exposes all surfaces of the granules to the hot air, drying them quickly and uniformly. Fluidized bed drying requires less time than other methods, avoids hot spots, and allows for drying of heat-sensitive materials.