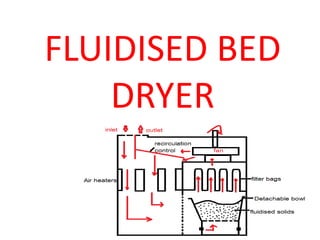

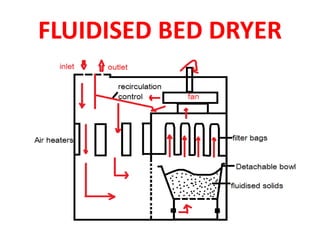

A fluidized bed dryer uses hot air to fluidize and dry granular materials. Hot air is passed through the granules in a perforated container, lifting the granules and suspending them in the air stream. This allows for uniform drying as the hot air surrounds each granule. Fluidized bed dryers can be vertical or horizontal and are made of stainless steel or plastic. They are used to efficiently dry materials for tablet production in 20-40 minutes, much faster than tray drying.