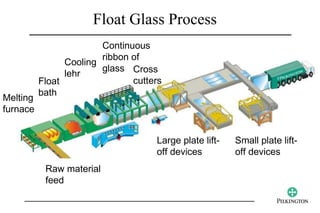

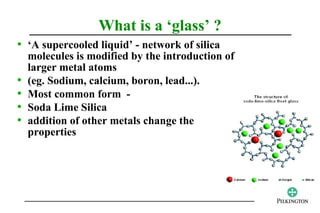

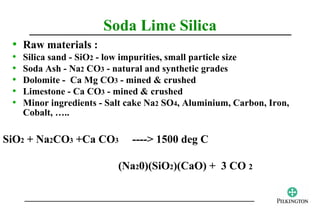

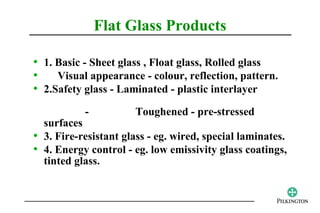

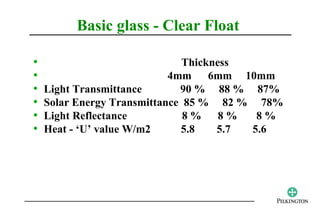

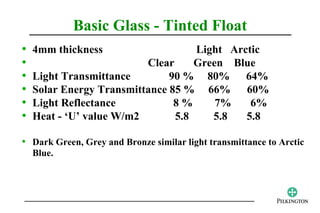

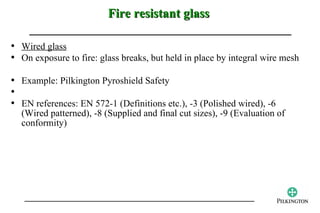

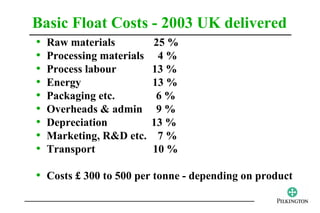

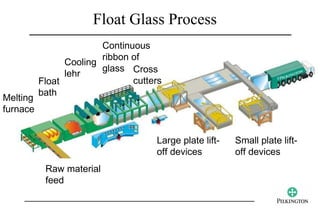

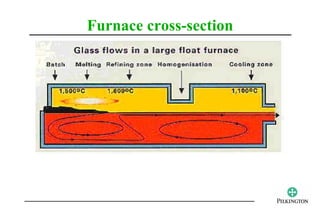

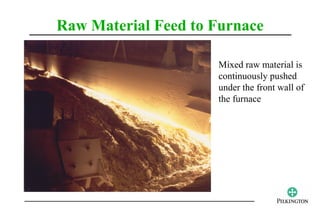

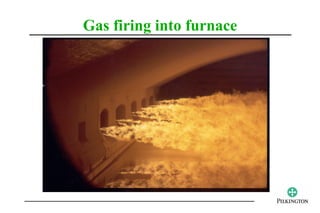

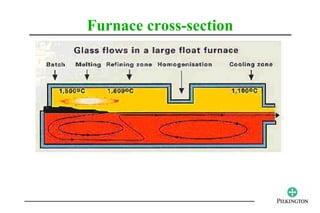

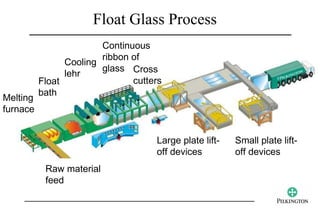

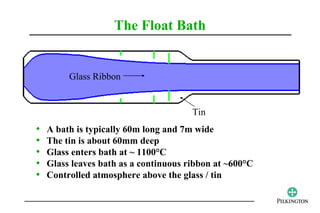

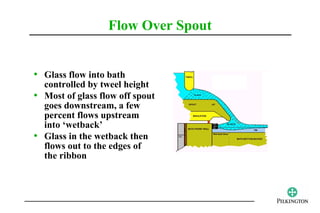

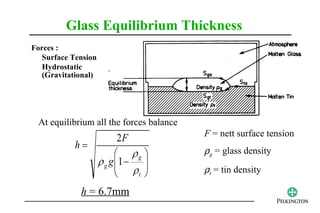

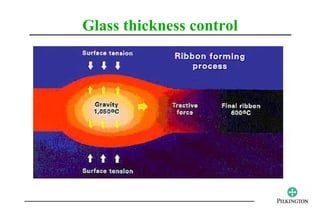

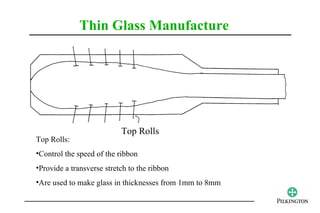

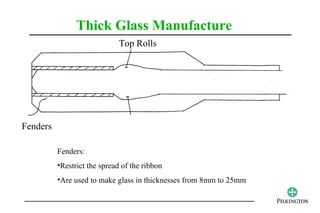

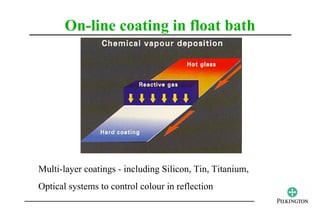

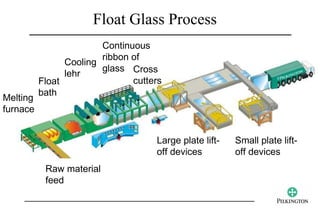

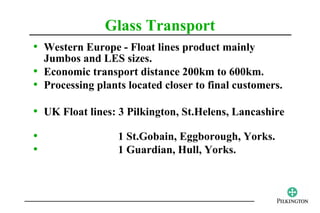

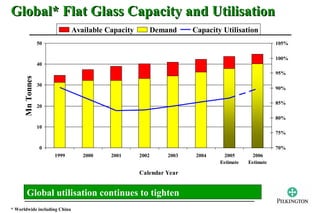

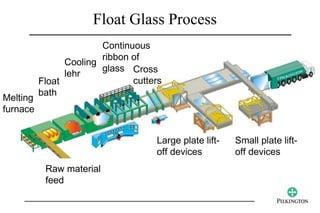

The document outlines the manufacturing process and types of flat glass products, detailing ingredients, properties, and various applications such as safety and fire-resistant glass. Key production methods include float glass processing, coating, and laminating, with specific attention to energy efficiency with low emissivity and self-cleaning features. It also provides insights into production costs and global capacity utilization trends in the flat glass market.