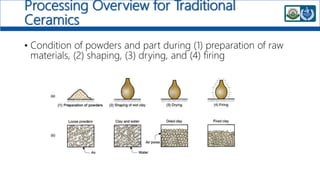

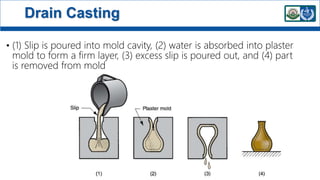

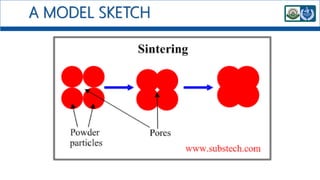

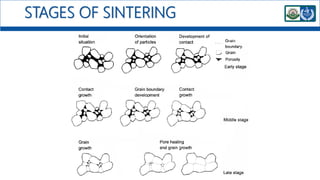

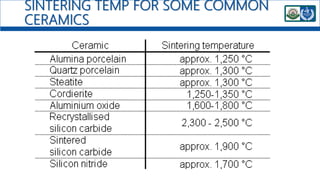

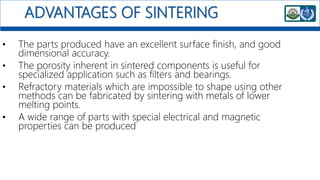

This document discusses the processing of traditional and new ceramics. It describes the key steps in ceramic processing which include preparation of raw materials, shaping, drying/dewatering, and firing/sintering. For traditional ceramics, the raw materials are naturally occurring minerals that are comminuted into powder and shaped using methods like slip casting or plastic forming before being dried and fired. New ceramics use synthetic powders and advanced shaping methods like dry pressing, hot pressing, or isostatic pressing, followed by sintering to achieve final densification. Sintering is a critical heat treatment process that bonds ceramic particles without melting by facilitating mass transfer through diffusion.

![ENGINEERING CERAMICS

MET 203

Maxwell Owusu

[BSc., MSc.]

Maxwell.owusu@stu.edu.gh/ +233-261-268565](https://image.slidesharecdn.com/ceramicprocessing-211213155712/75/Ceramic-processing-1-2048.jpg)