Industrial Training at Asahi India Glass Ltd.

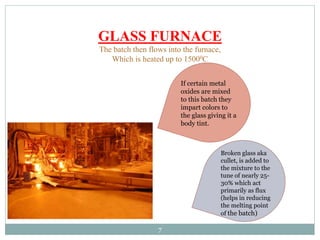

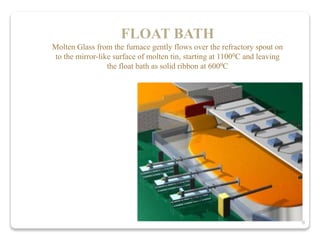

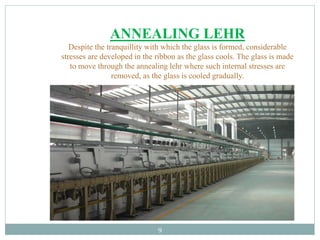

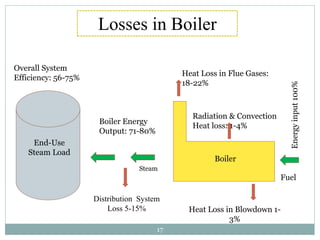

The document discusses Ajeet Kumar Saini's industrial training at Asahi India Glass Ltd (AIS Glass). It provides information on the company and describes the six step float glass manufacturing process used by AIS, from mixing raw materials to packaging the final product. It also includes calculations of the boiler efficiency at 71.67% and cooling tower efficiency at 55%.