The document discusses corrosion of rotary kiln shells caused by chemicals from waste fuels penetrating the refractory lining. It proposes using a water-based ceramic coating and sacrificial stainless steel membrane welded to the kiln shell to protect it. The coating and steel membrane combination has proven most effective in the author's experience at minimizing shell corrosion and the high replacement costs. Additional measures like using mortar instead of shims for brick installation and selecting bricks with low thermal conductivity can further reduce corrosion.

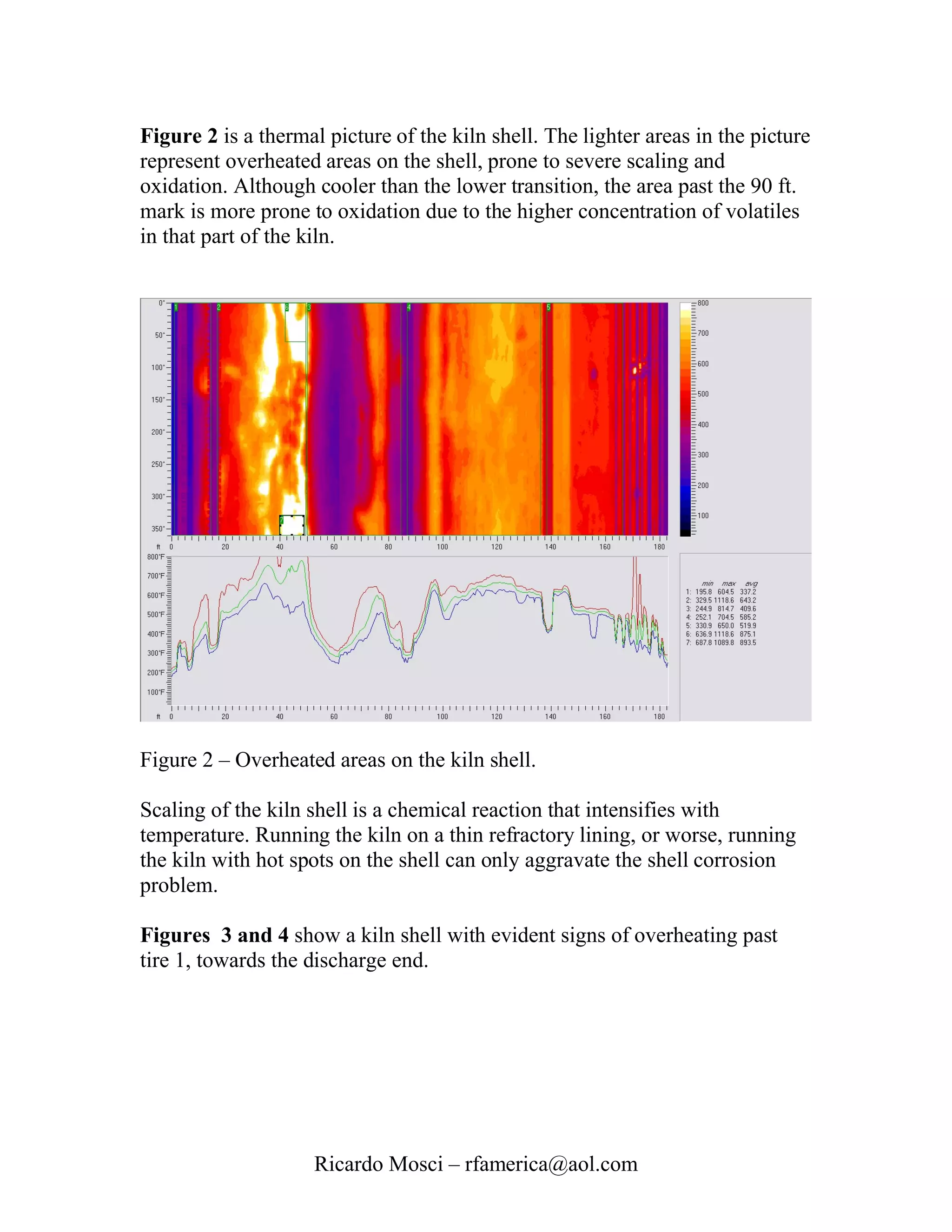

![CORROSION MECHANISM

Chlorine, possibly from waste fuels, reacts with Potassium in circulation

forming Sylvite (KCl). Sylvite has a very high vapor pressure and it

penetrates through the brickwork open porosity and joints, in vapor form.

Next it condenses into liquid and the liquid migrates towards the kiln shell

where it condenses in cristal form. The Sulphur follows a similar path but

SO3 is known to attack CaO in the brick and carry it towards the kiln shell

as Anhydrite or even CaS, if the kiln conditions are reducing.

Once these salts collect against the carbon steel shell, it only takes a kiln

shutdown to get the missing link in the corrosion process: water. Being

hygroscopic, these salts absorb and react with water, providing the anions

[SO4]-2, [SO3]-2, Cl-, which in turn attack the steel forming magnetite

(Fe3O4), hematite (Fe2O3), pyryte (FeS), goethite (Fe3+O(OH) ). Chlorine is

the oxidizing element and takes part in the corrosion process, but it is rarely

found attached to iron in corrosion products.

Usually the products of oxidation show a layered composition: Wustite

(FeO) on the cold face, Magnetite (FeO.Fe2O3) in the middle and Hematite

(Fe2O3) towards the brick lining. The problem with these oxides is that they

are porous and consequently cannot protect the steel shell against further

attack.

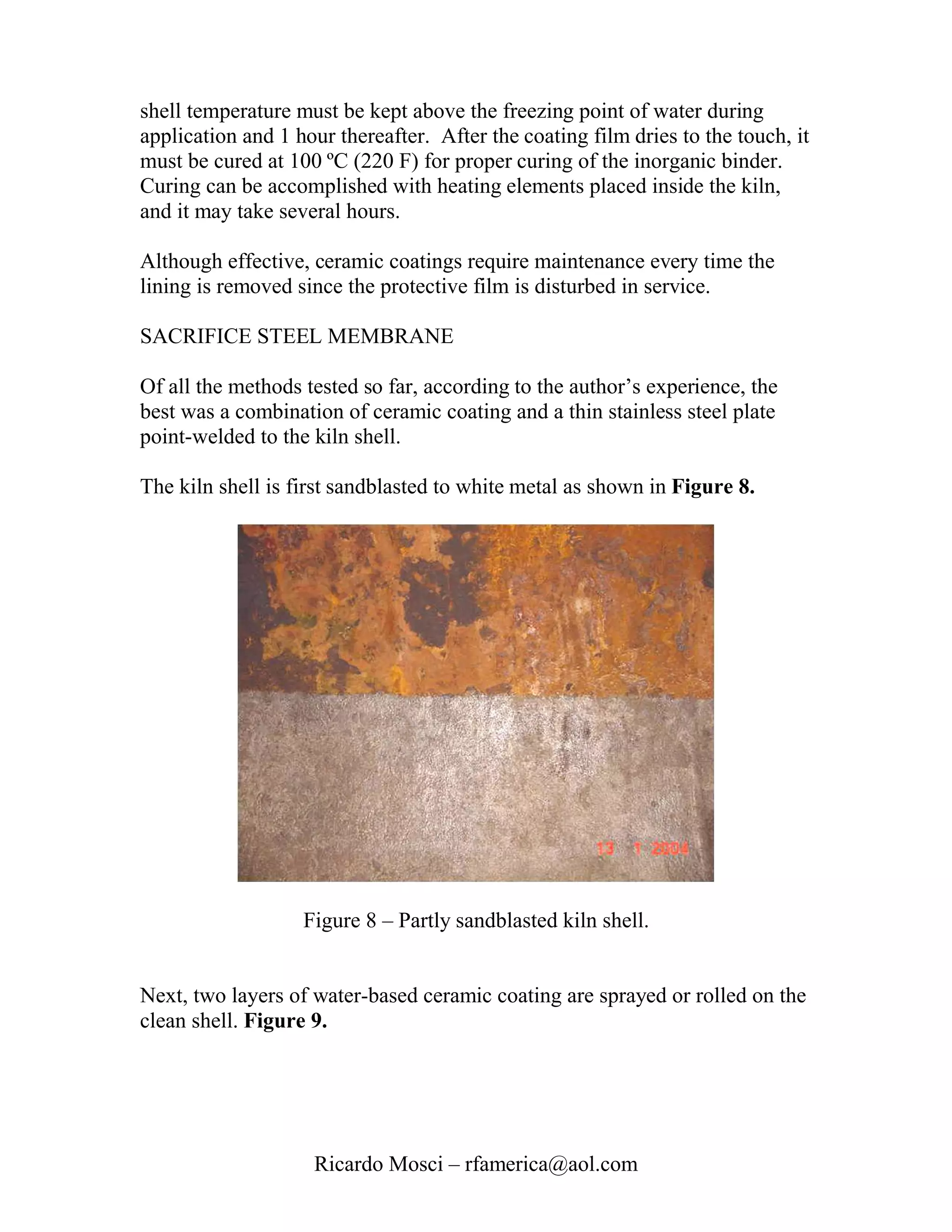

Figure 1 shows a corroded kiln shell after removal of the brick lining.

The corrosion process is in its preliminary stages since the oxides layer is

relatively thin.

Figure 1 – Mild corrosion of the kiln shell.

Ricardo Mosci – rfamerica@aol.com](https://image.slidesharecdn.com/2shellcorrosion-13009777609991-phpapp02/75/Kiln-Shell-Corrosion-2-2048.jpg)