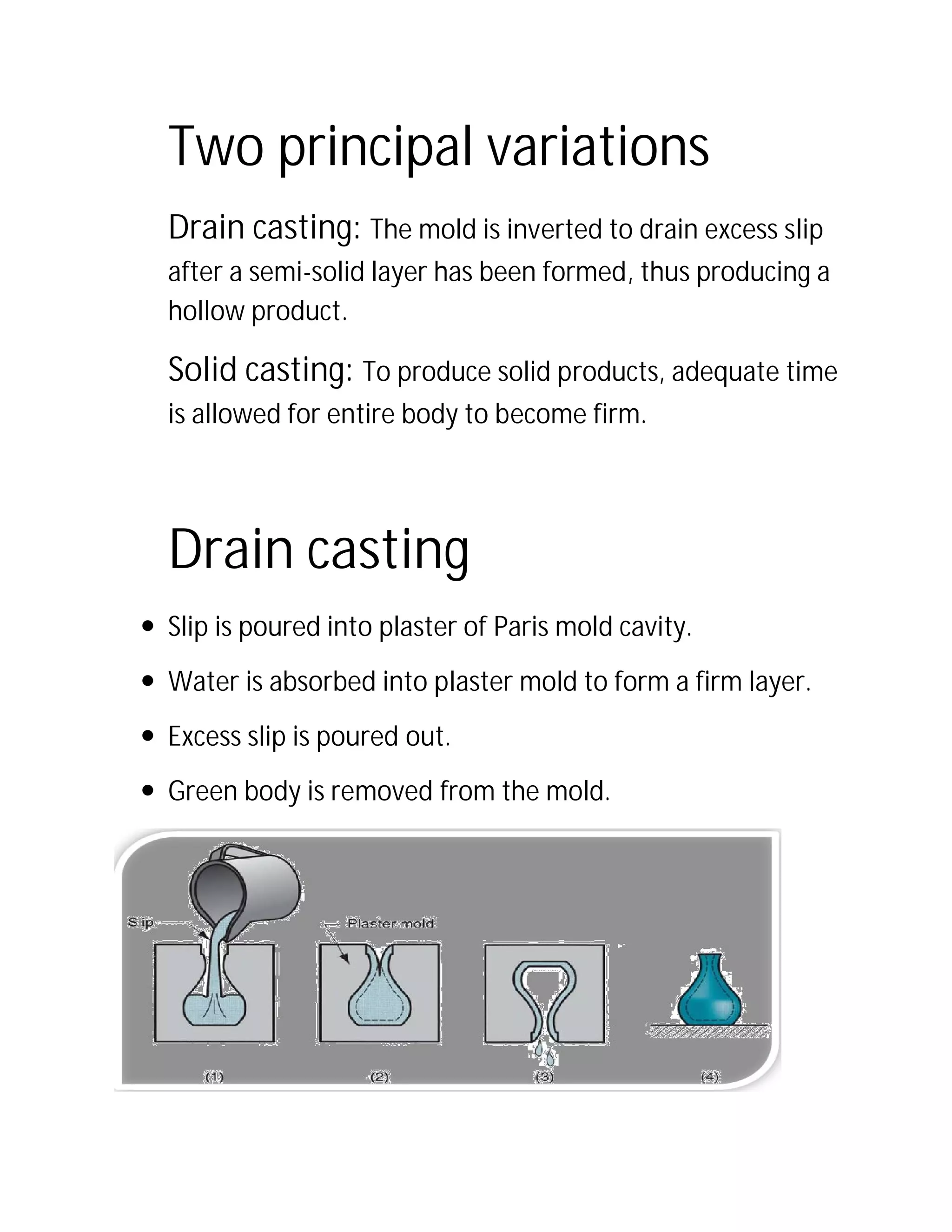

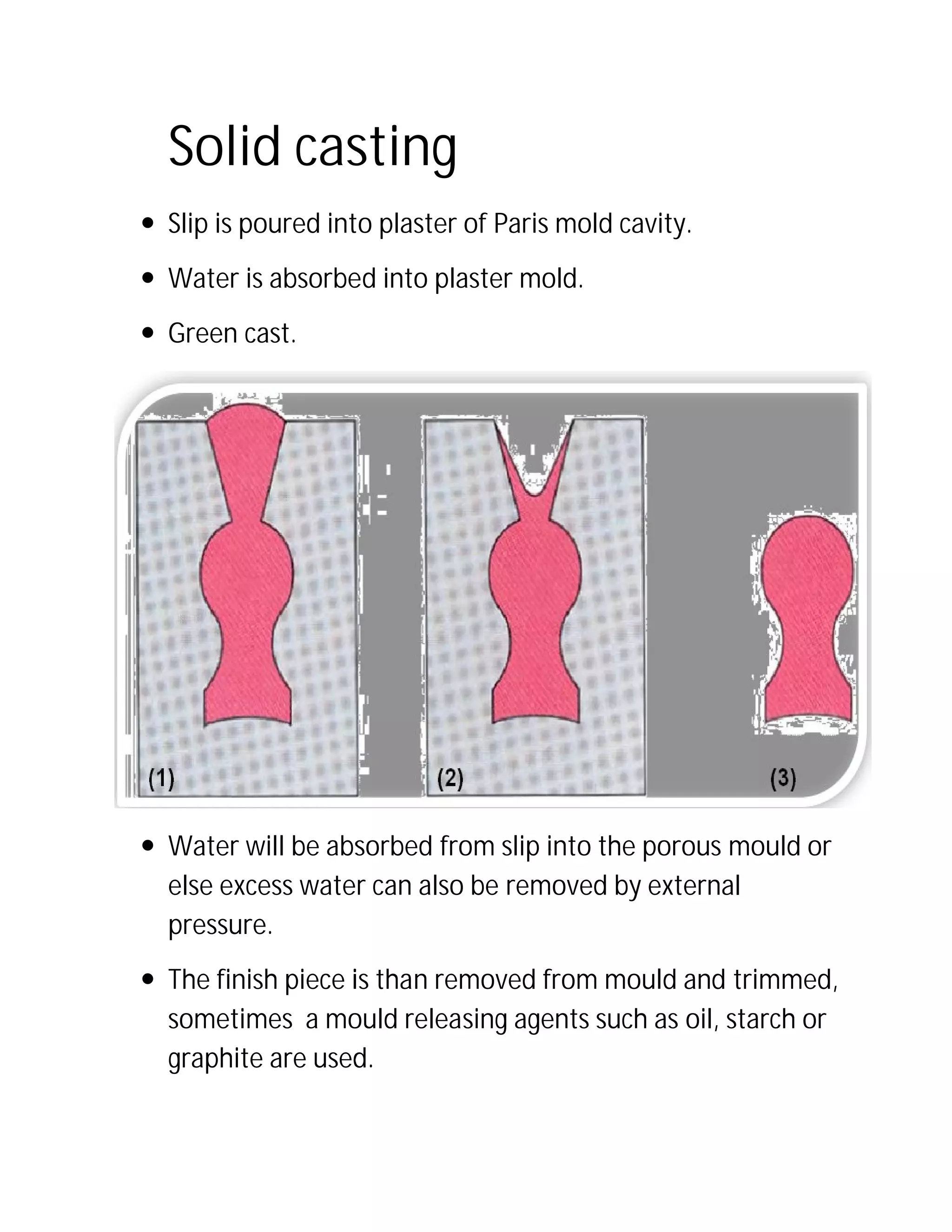

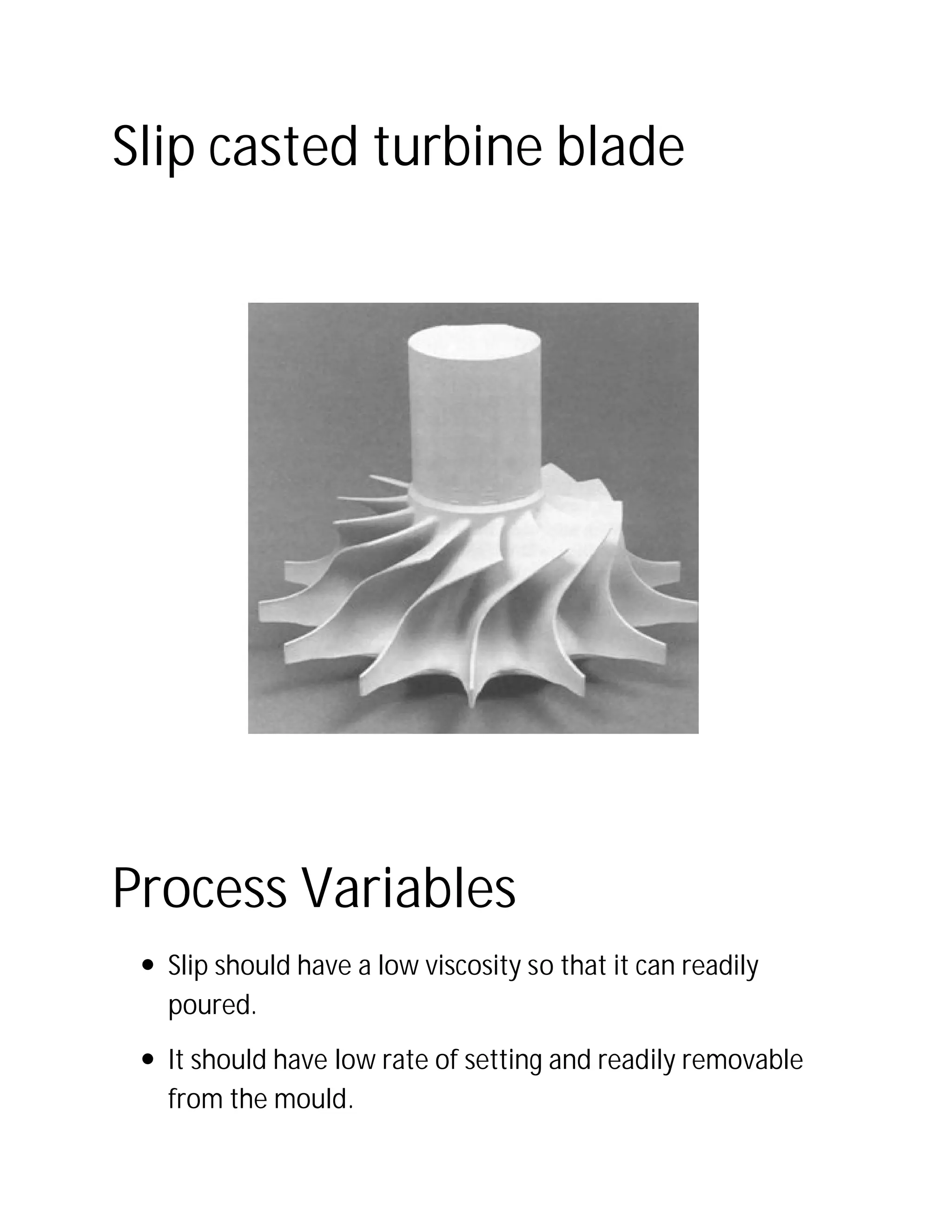

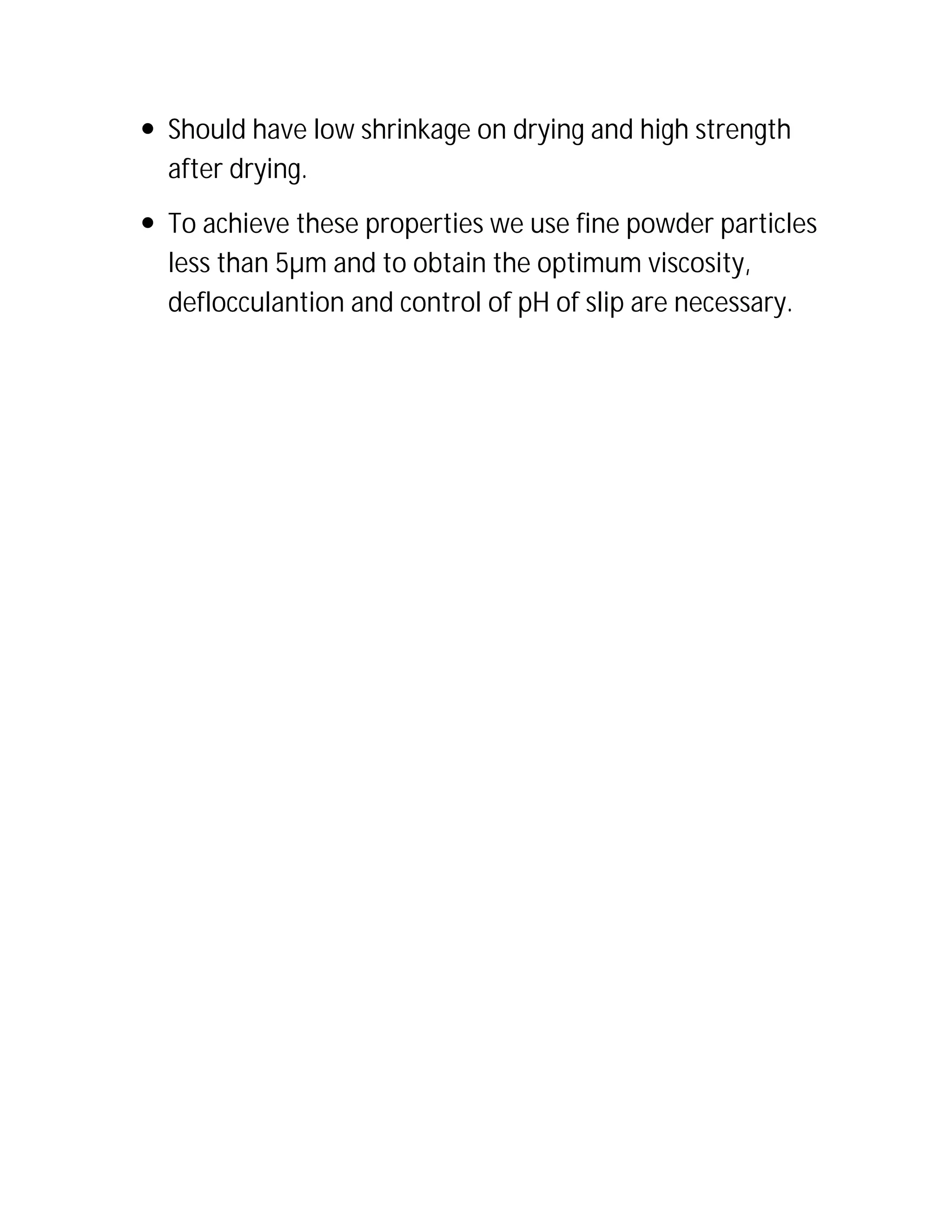

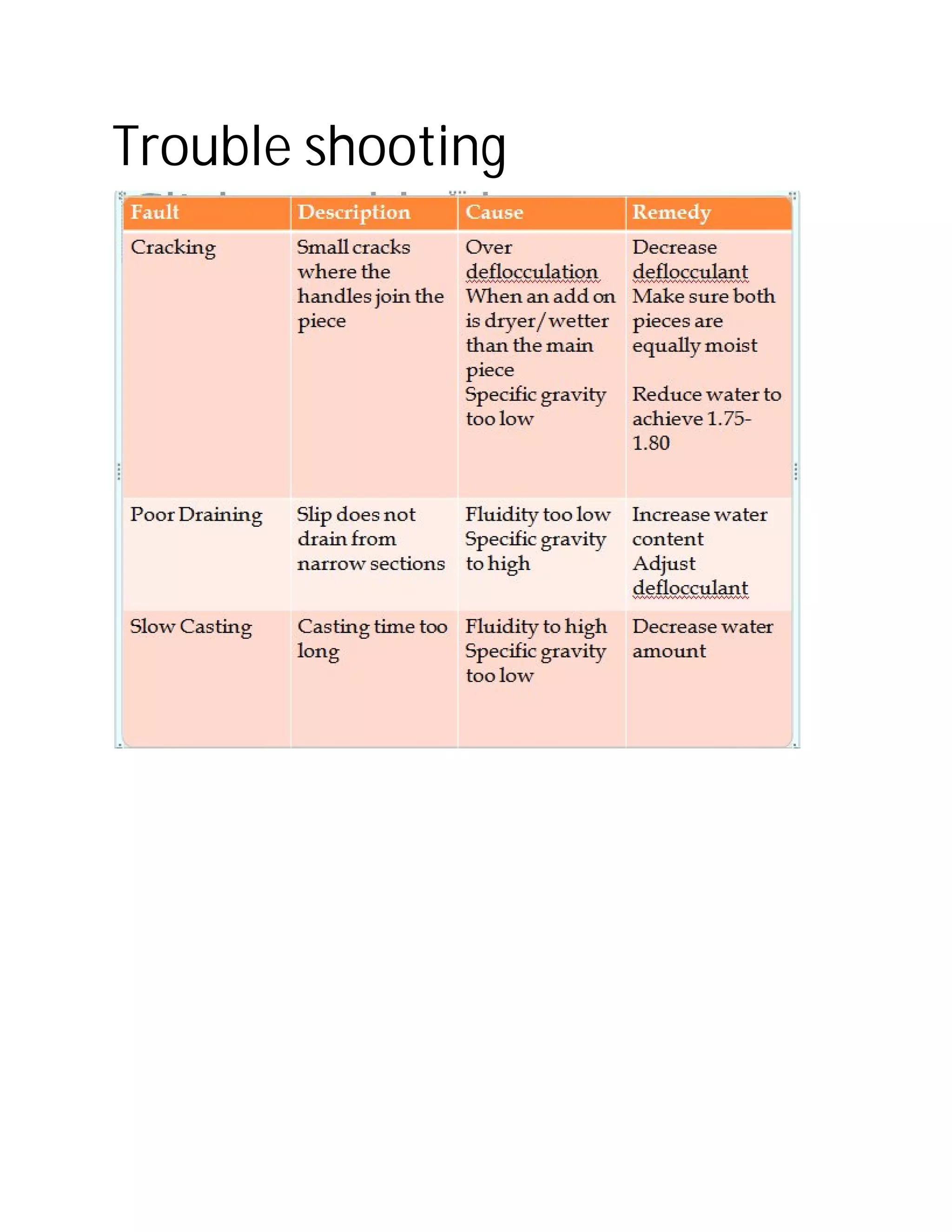

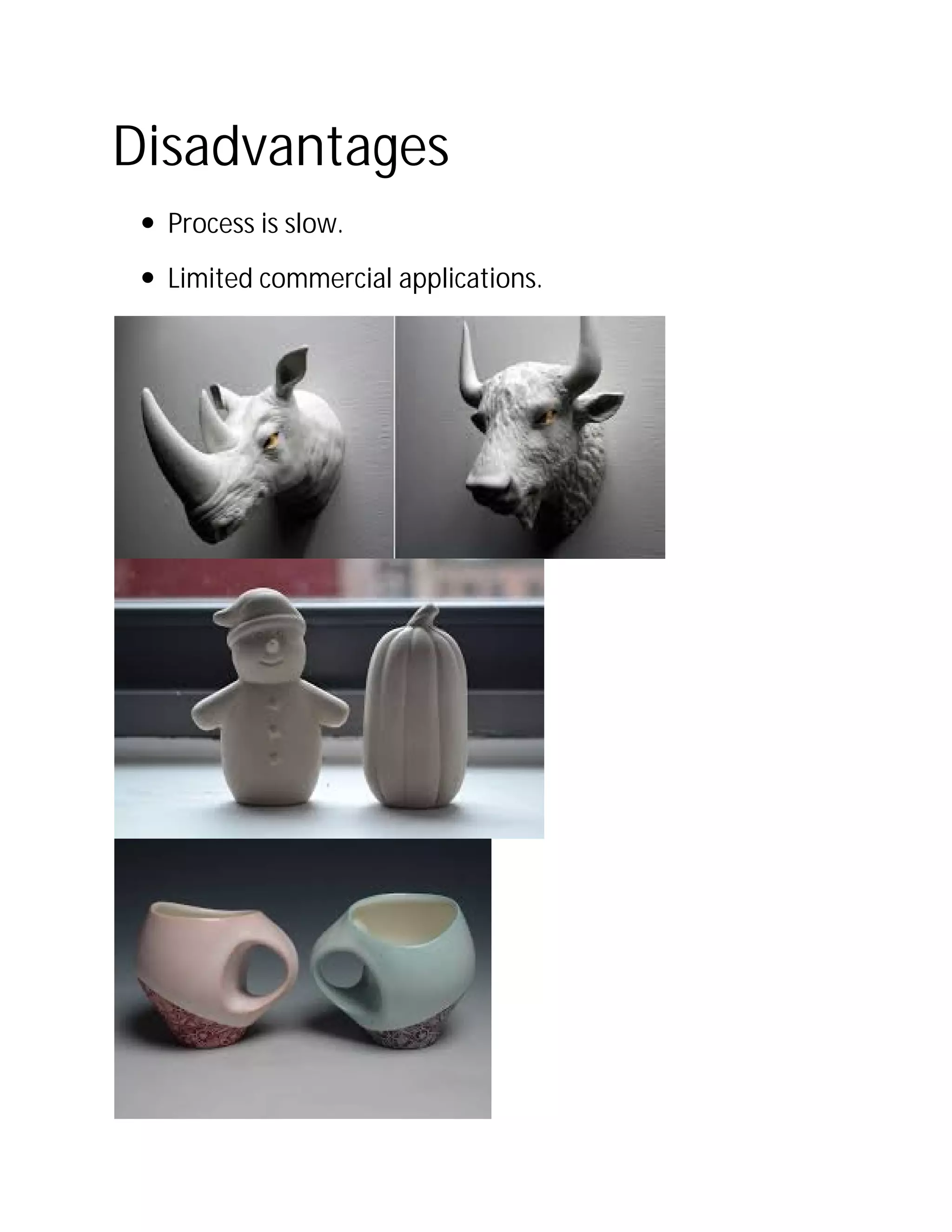

Slip casting is a process used to mass produce ceramic items like figurines, dishes, and flower pots. A liquid suspension of ceramic powder called a slip is poured into a plaster mold. Water from the slip is absorbed by the porous mold, leaving a solid ceramic layer. Excess slip is drained out. The piece is then dried and fired. There are two main methods - drain casting produces hollow items while solid casting allows the entire mold cavity to solidify. Key factors that affect the process include the viscosity and setting rate of the slip as well as shrinkage and strength of the final piece. Slip casting allows intricate shapes and sizes but the process is slow with limited commercial applications.