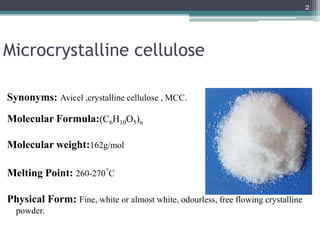

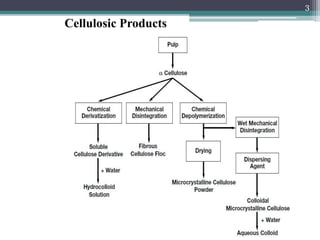

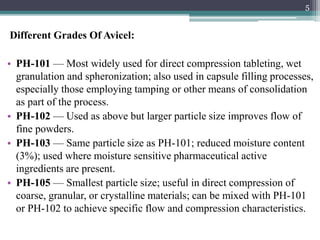

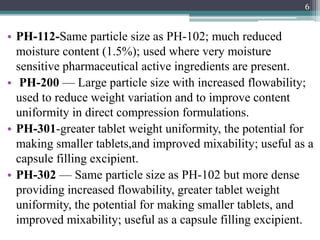

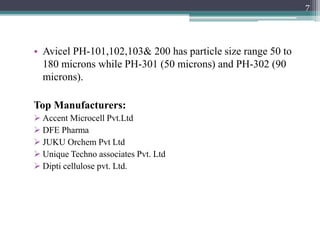

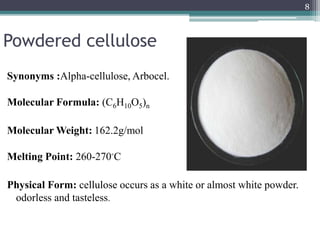

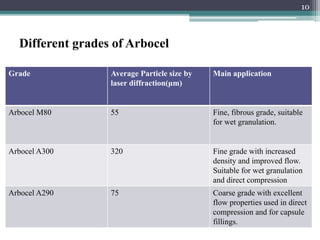

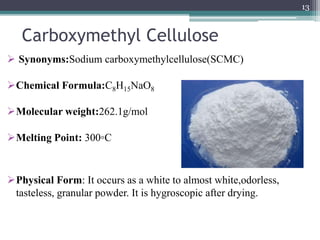

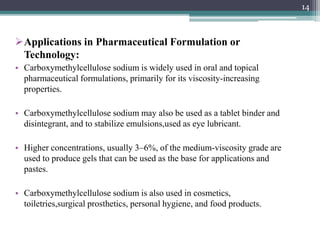

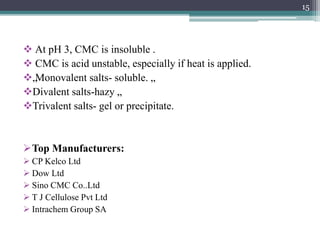

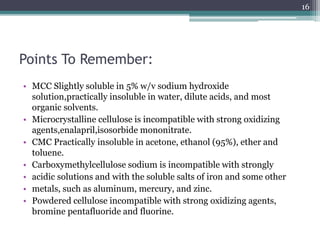

The document discusses pharmaceutically important cellulose, focusing on microcrystalline cellulose (Avicel) and powdered cellulose, including their properties, production, and applications in the pharmaceutical industry. It details various grades of Avicel with specific characteristics suitable for different applications, as well as the chemical nature and uses of powdered cellulose as a bulking agent and tablet diluent. Additionally, the document covers carboxymethyl cellulose, its properties, applications, and compatibility with other substances.