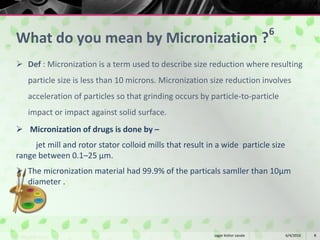

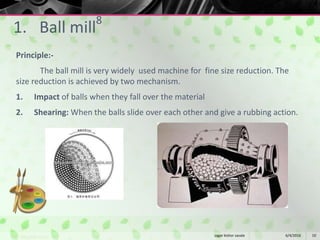

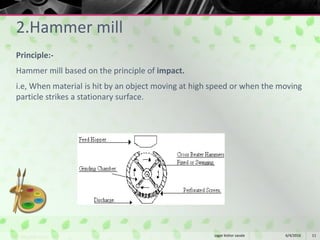

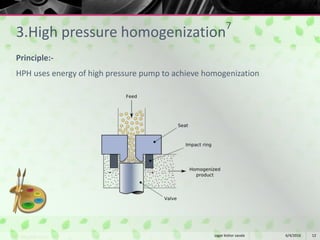

Micronization is a technique used to reduce particle size to less than 10 microns in order to enhance drug solubility and bioavailability. It involves accelerating drug particles through impacts with other particles or solid surfaces using techniques like jet milling or rotor stator colloid mills. The document discusses various methods of micronization including ball milling, high pressure homogenization, and supercritical fluid processes. It provides examples of how these techniques work and notes that micronization is useful for improving solubility of poorly water soluble drugs.

![SOLUBILITY ENHANCEMENT BY

MICRONIZATION

6/4/2016 1sagar kishor savale

Mr. Sagar Kishor Savale

[Department of Pharmaceutics]

avengersagar16@gmail.com

2015-2016

Department of Pharmacy (Pharmaceutics) | Sagar savale](https://image.slidesharecdn.com/solubilityenhancementbymicronization-160604065600/85/Micronization-Solubility-Enhancement-by-Micronization-1-320.jpg)