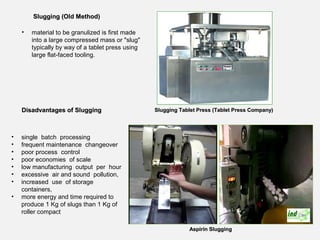

Dry granulation is used to granulate materials that cannot withstand heat or moisture. There are two main dry granulation methods: slugging and roller compaction. Roller compaction is now more commonly used. It involves compressing powder between two rollers to form dense flakes that are then milled into granules. Roller compaction offers continuous processing, better control, and higher output compared to slugging. Key variables of roller compaction include roller pressure, gap, and speed. Dry granulation is suitable for heat- or moisture-sensitive drugs and can improve tablet properties.