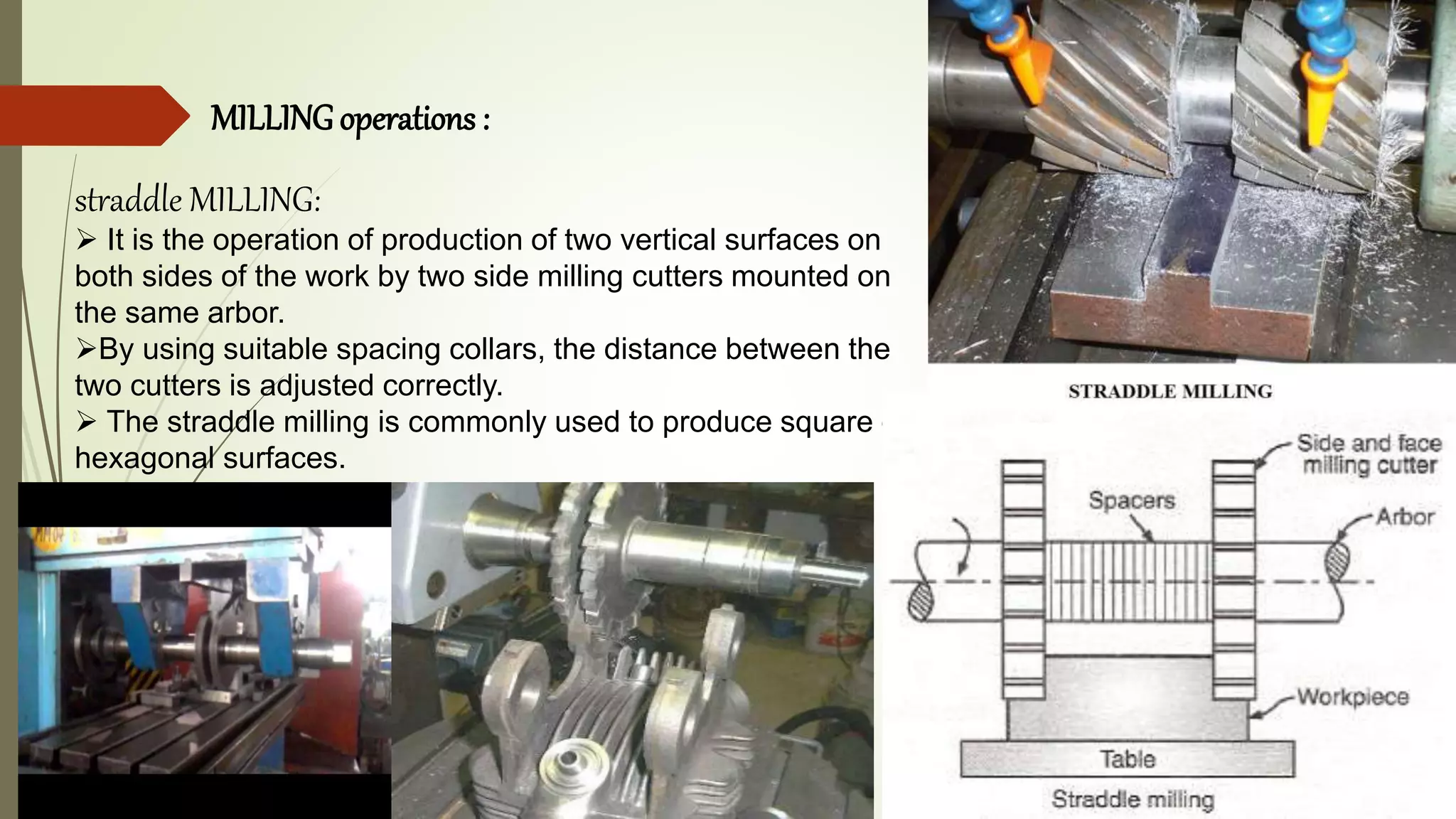

This document discusses different types of milling operations including plain milling, face milling, angular milling, form milling, straddle milling, gang milling, end milling, and keyway milling. It provides details on each operation such as the cutters used, surfaces produced, and applications. The document is authored by Polayya Chintada who is an Assistant Professor and discusses these milling operations for a course on Metal Cutting and Machine Tools.