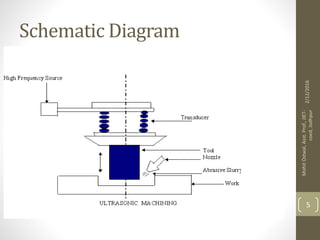

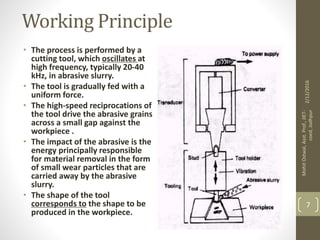

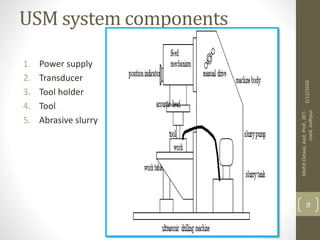

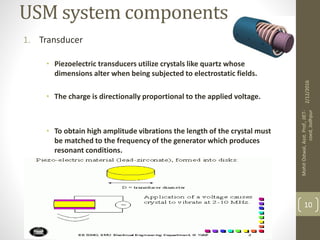

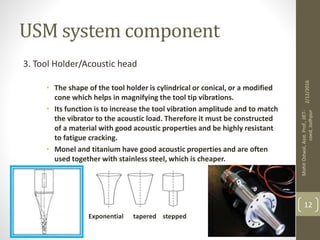

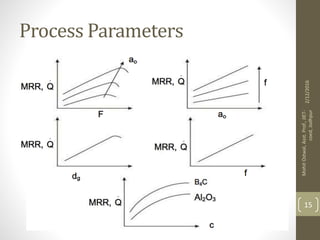

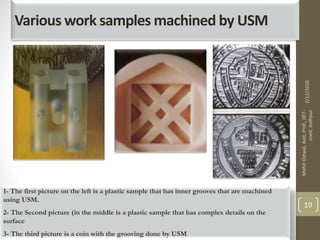

The document discusses ultrasonic machining (USM), which uses high-frequency vibrations and an abrasive slurry to erode material. USM can machine hard and brittle materials by using a vibrating tool to drive abrasive particles against the workpiece. The document outlines the principles, components, process parameters, applications, and advantages/disadvantages of USM. It describes how the tool, transducer, abrasives, and other system parts work together to remove material through brittle fracture caused by abrasive particle impacts. Examples are given of complex features that can be machined using USM.