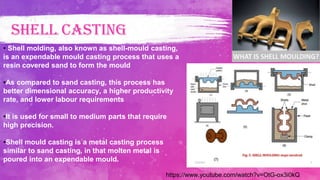

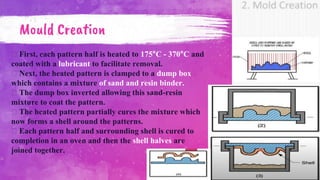

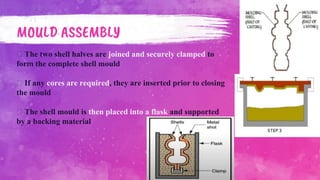

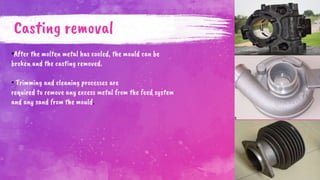

This document provides information about shell casting production technology. It discusses shell casting as a metal casting process where a resin-coated sand forms an expendable mold, allowing for higher precision and productivity than sand casting. The document outlines the shell casting process which involves pattern creation, mold creation by coating a heated pattern with sand-resin mixture, mold assembly, pouring molten metal, cooling, and casting removal. Typical applications include small to medium parts for industries like automotive and defense.