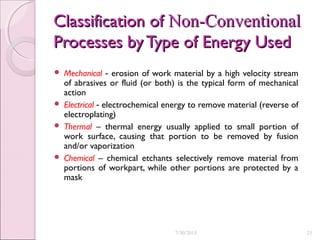

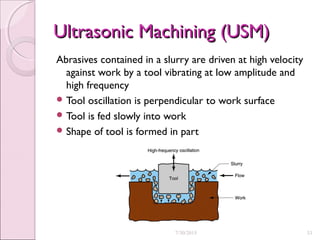

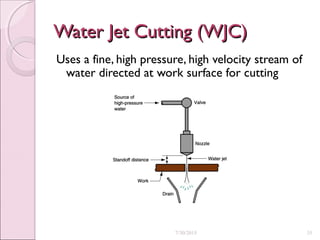

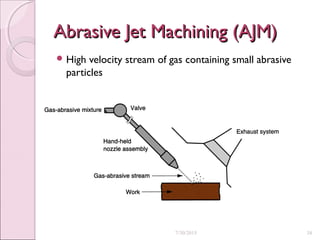

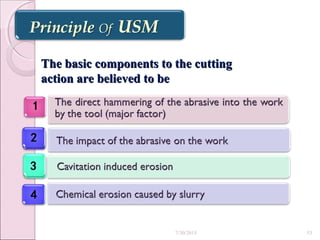

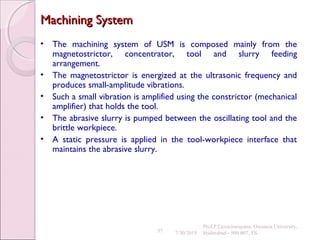

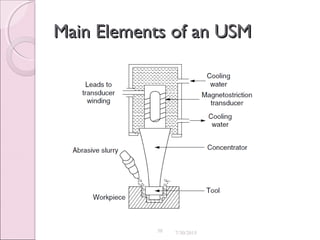

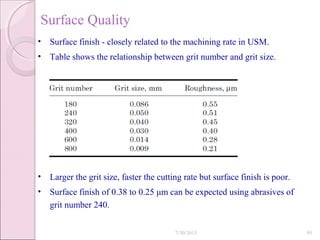

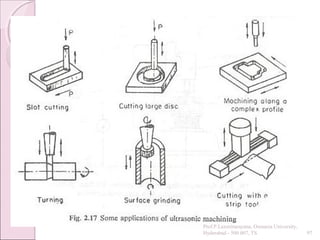

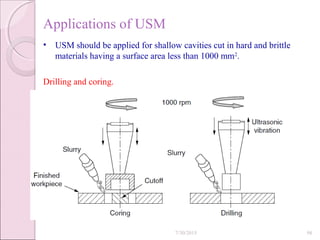

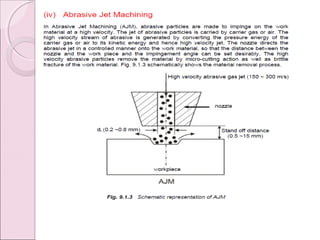

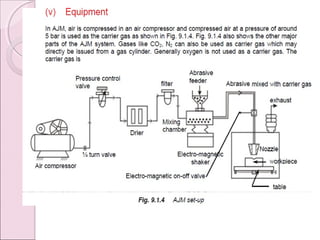

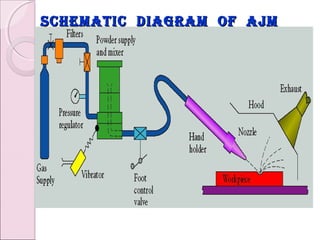

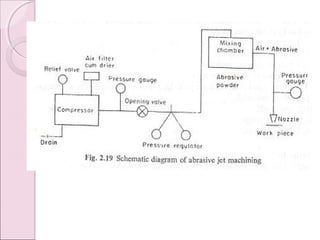

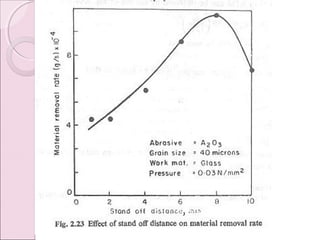

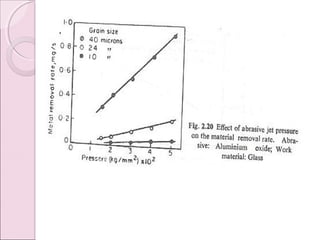

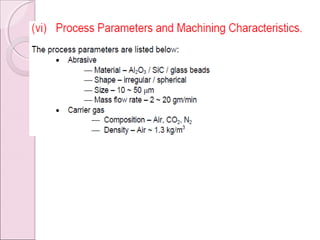

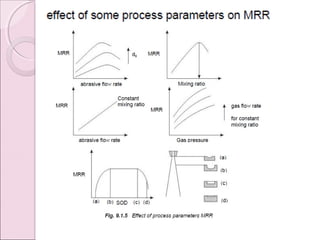

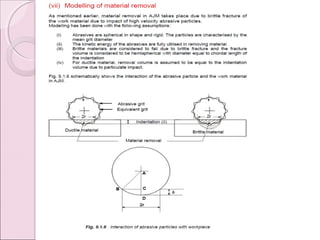

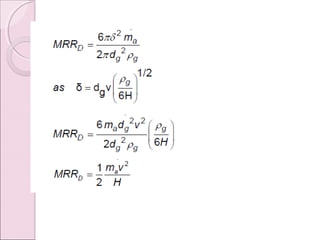

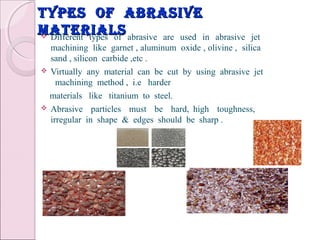

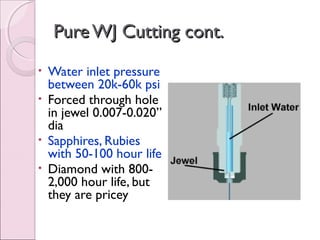

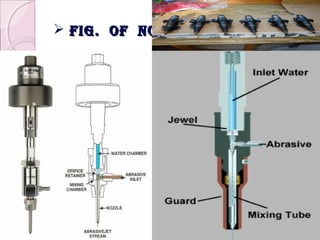

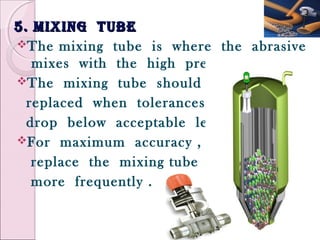

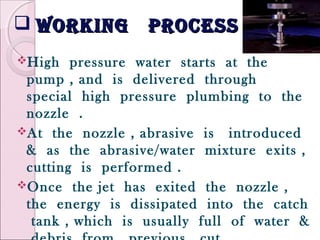

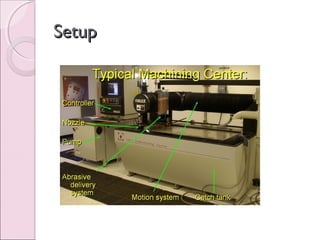

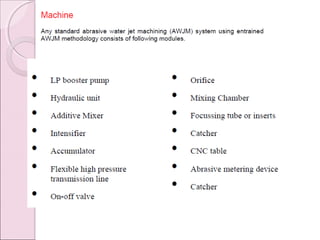

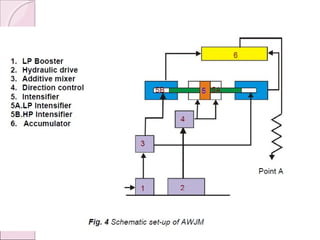

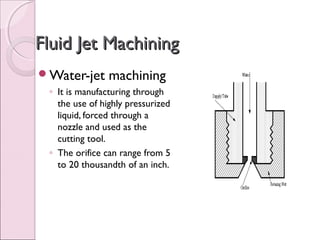

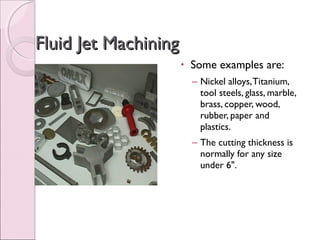

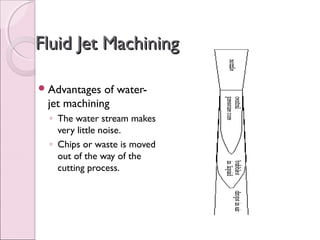

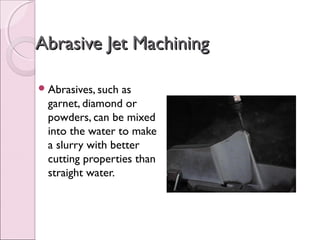

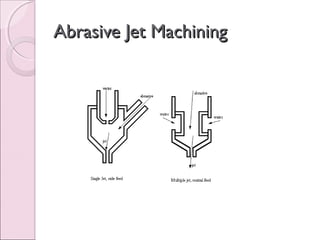

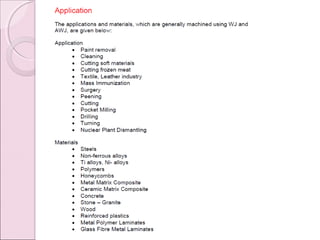

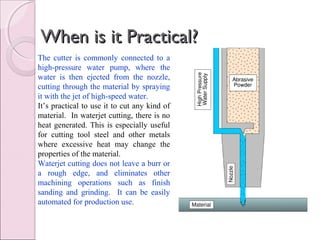

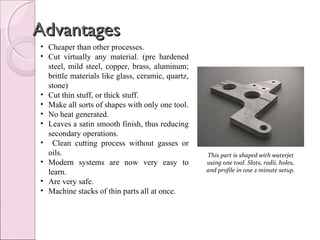

This document discusses conventional and non-conventional machining methods. It begins by defining conventional machining as using a sharp cutting tool for removal of metal. Non-conventional machining does not require physical contact between tool and workpiece and instead uses tools like laser beams or water jets. The document then covers several non-conventional machining processes in more detail like ultrasonic machining, abrasive jet machining, and water jet machining. It concludes by comparing characteristics of conventional and non-conventional machining.