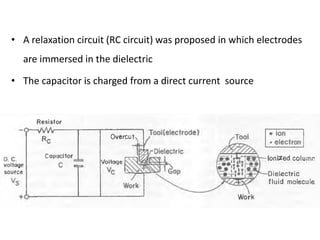

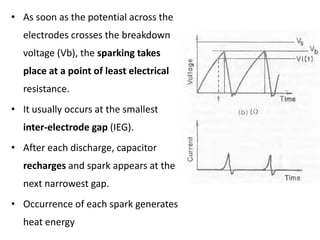

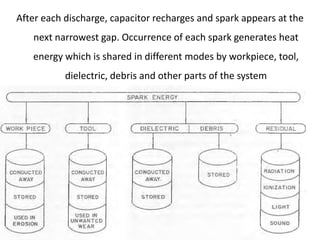

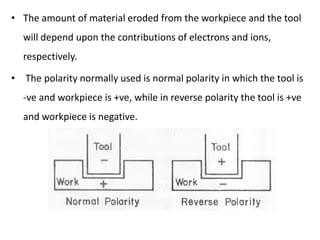

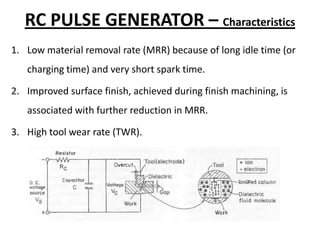

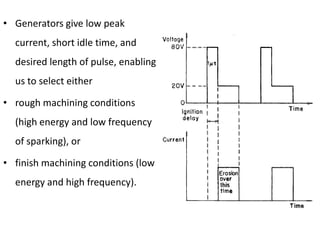

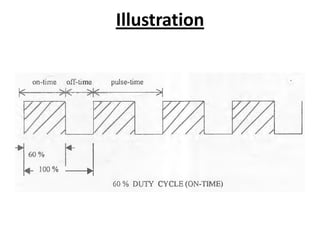

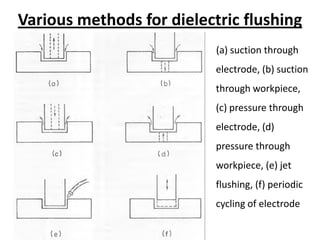

Electric discharge machining (EDM) is a thermoelectric process that uses sparks produced by electric discharges to remove material from conductive workpieces. Short duration sparks erode material by melting and vaporizing small amounts from both the tool and workpiece electrodes. Effective dielectric flushing is needed to remove debris from the gap and improve machining accuracy and surface finish. Process parameters like voltage, current, pulse duration and frequency can be controlled to achieve different material removal rates and surface finishes for roughing and finishing operations. Common electrode materials include graphite, copper and brass due to their machinability and electrical conductivity.