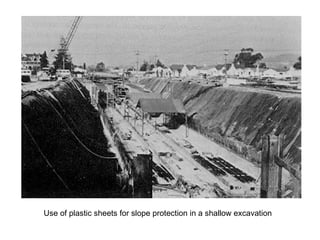

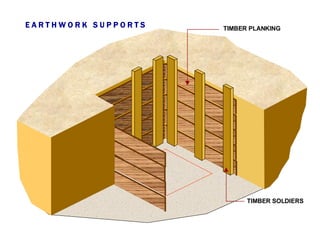

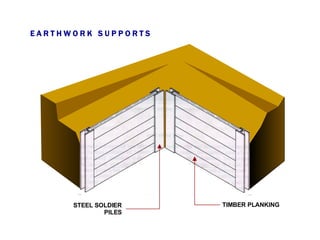

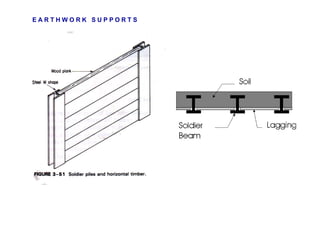

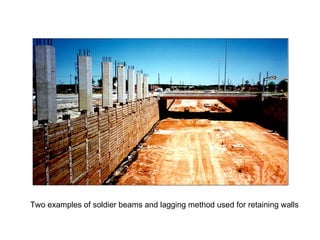

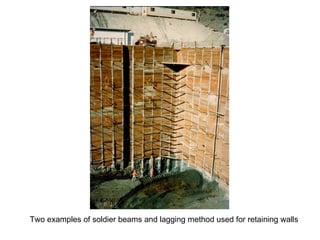

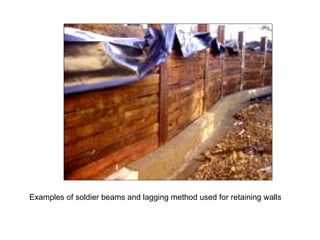

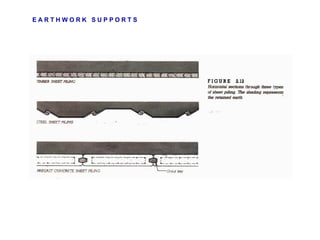

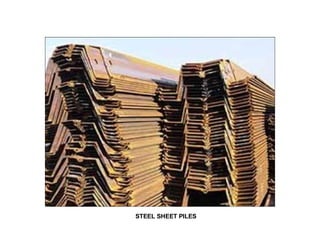

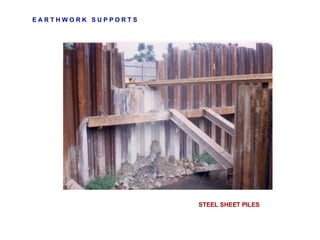

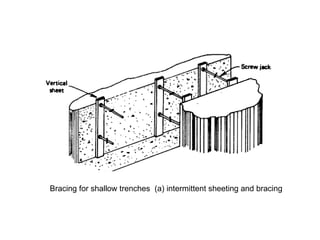

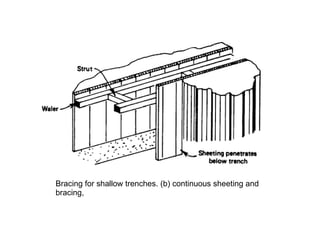

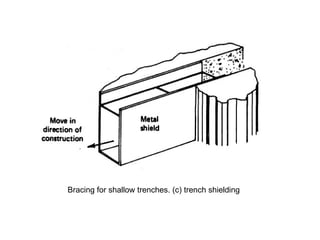

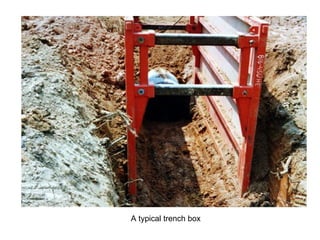

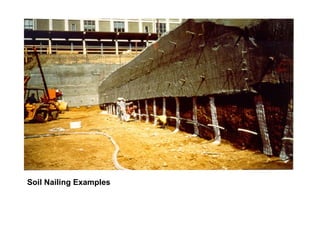

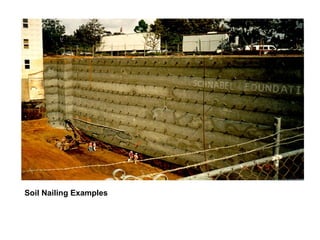

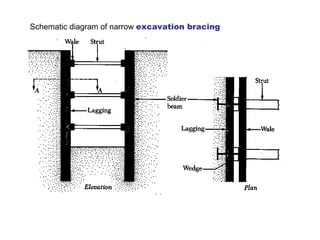

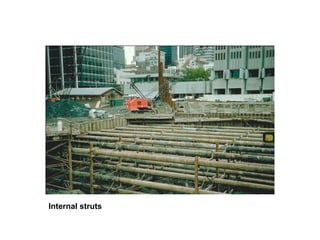

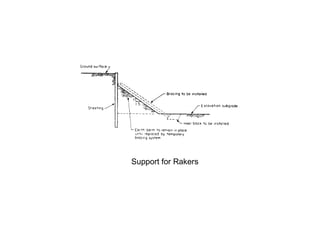

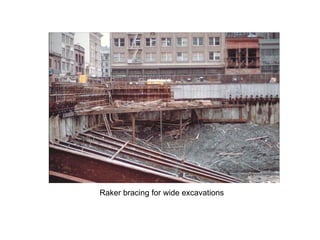

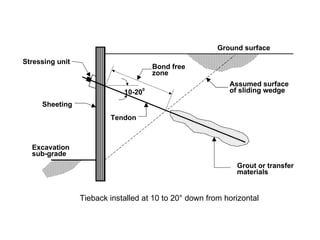

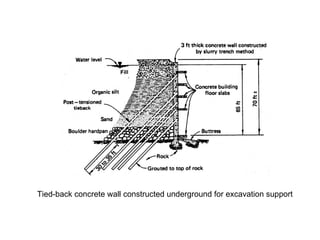

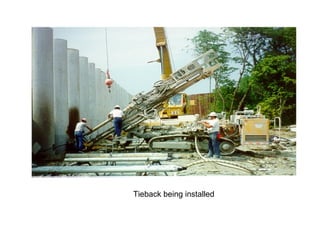

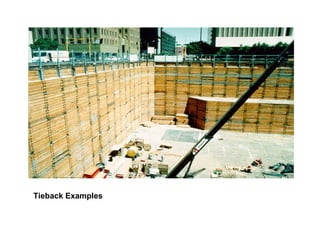

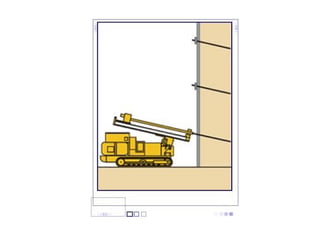

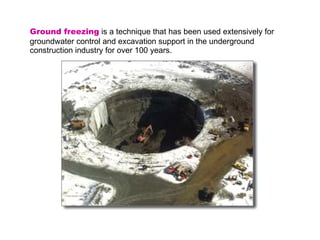

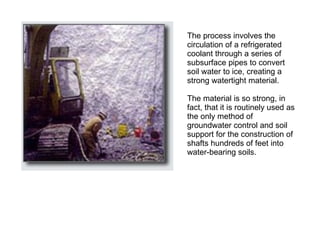

The document discusses different methods for excavation support and retaining walls, including soldier beams and lagging, sheet piling, soil nailing, tiebacks, and ground freezing. It provides examples and diagrams to illustrate soldier beams and lagging, bracing for shallow trenches, soil nailing, raker bracing for wide excavations, tied-back concrete walls, and tieback installation. It also provides more detail on ground freezing, describing it as a technique used for over 100 years for groundwater control and excavation support by circulating refrigerant through subsurface pipes to freeze soil and create a strong, watertight material.